XYC Metalworks

- Lorem donec massaRated 3 out of 5

- Velit aliquet sagittisRated 3 out of 5

- Magna etiam tempor orciRated 3 out of 5

- Tristique et egestas quis ipsumRated 3 out of 5

- Cum sociis natoqueRated 3 out of 5

- Pellentesque elit eget gravidaRated 3 out of 5

Quick Summary

Rhoncus aenean vel elit scelerisque mauris pellentesque pulvinar pellentesque habitant. Ridiculus mus mauris vitae ultricies leo. Ut ornare lectus sit amet. Eu augue ut lectus arcu. Egestas quis ipsum suspendisse ultrices.

Gravida rutrum quisque non tellus orci ac. Egestas dui id ornare arcu odio ut sem nulla. Sed elementum tempus egestas sed sed risus pretium. Lectus sit amet est placerat. Consequat semper viverra nam libero justo laoreet sit amet cursus.

Specs

- Pellentesque: Gravilmusa

- Cum sociis: Natoque

- Tristiquex: Egestas quis ipsum

- Velit aliquet: Sagittis

Pros

- Phasellus vestibulum lorem

- Ridiculus mus mauris vitae

Cons

- Gravida rutrum quisque

- Egestas dui id ornare arcu

Aluminium

- Home

- Product Reviews

- Aluminium

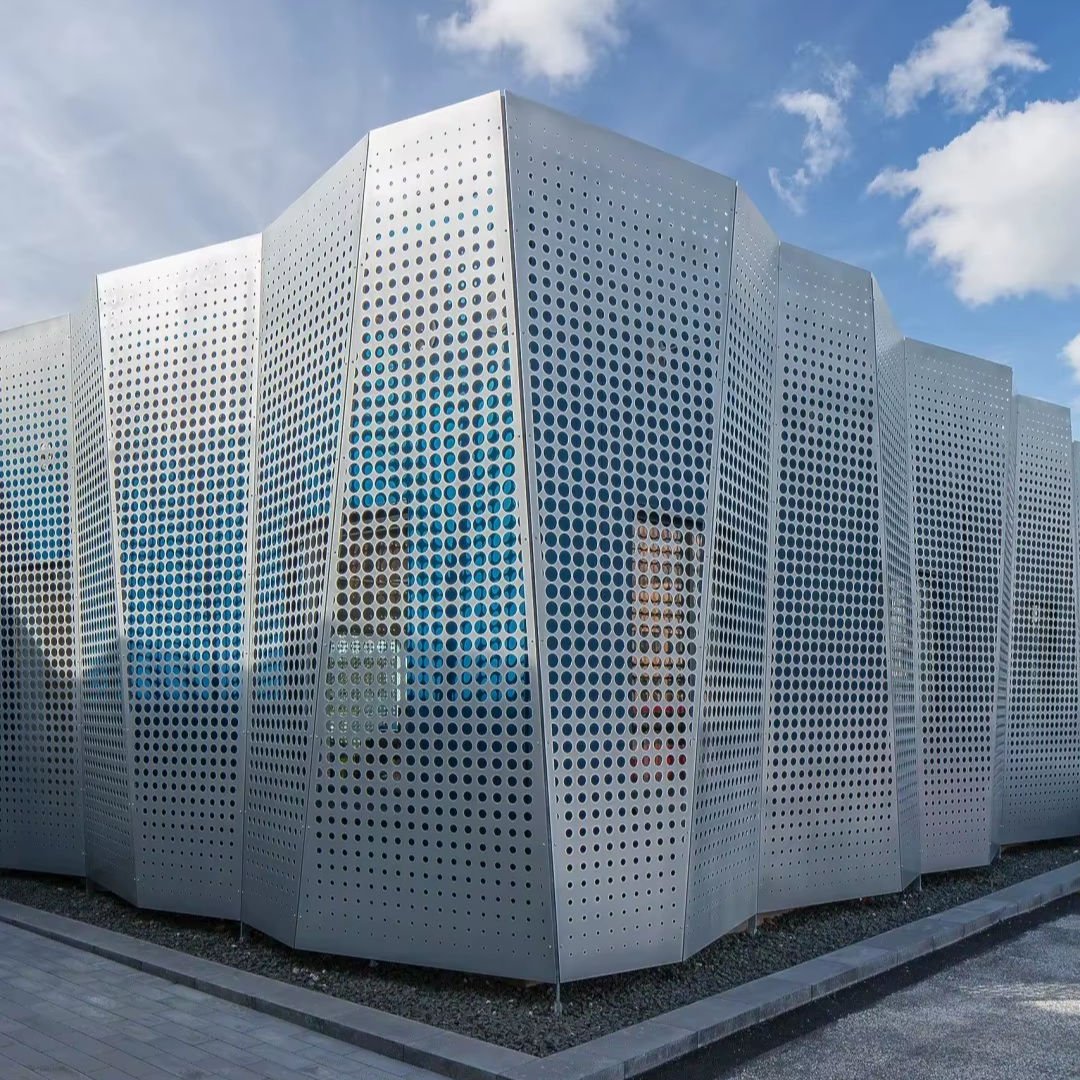

XYC Metalworks: Premium Custom Aluminum Fabrication for Engineered Solution

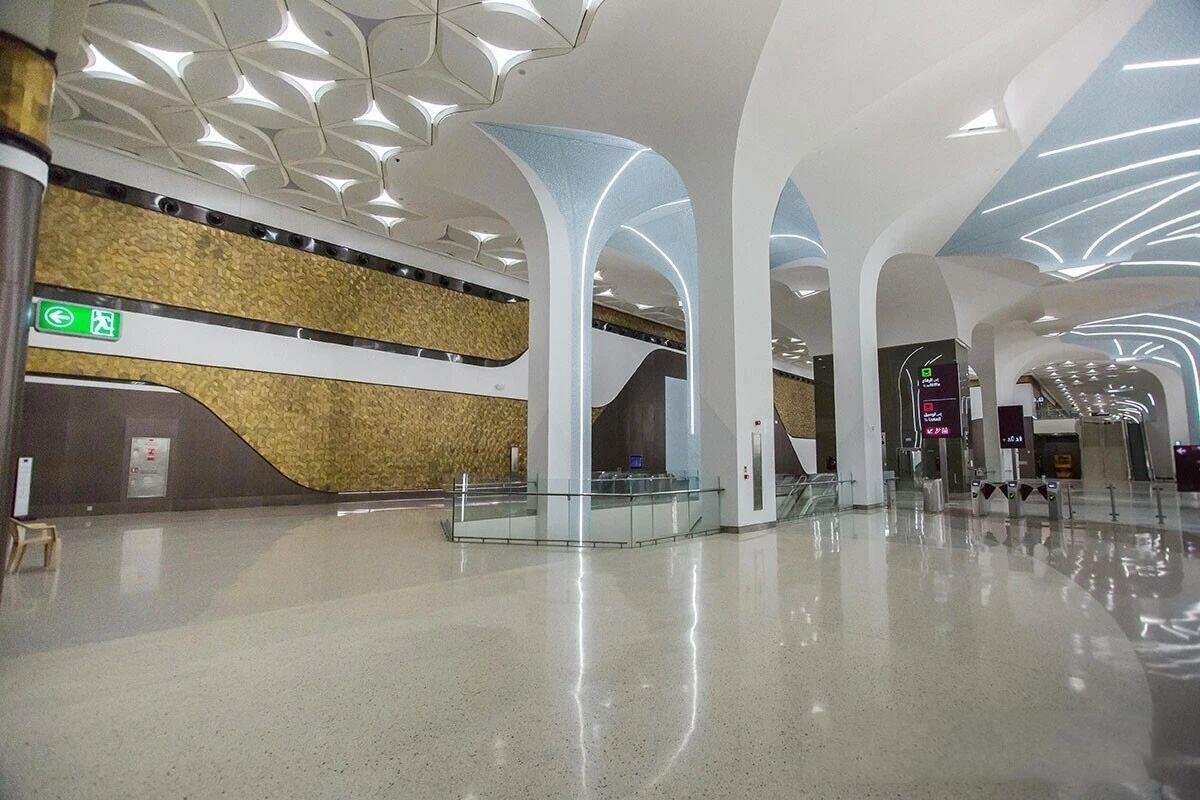

As a premier custom aluminum fabrication company, XYC Metalworks specializes in creating bespoke architectural aluminum solutions for major engineering and architectural projects. This page serves as an educational guide to the foundational aluminum materials we expertly utilize—primarily high-quality alloys 1100, 3003, 5052, and 6061.

While this information is provided for your reference and selection, our core service is to partner with you. Our team will analyze the specific details and requirements of your project to recommend and fabricate the most suitable aluminum products, ensuring optimal performance, durability, and aesthetics for your application.

We use the highest quality aluminum products, including aluminum sheets (coils, flat sheets), plates, and tubes. Renowned for their exceptional light weight, high strength-to-weight ratio, and superior corrosion resistance, our products are the ideal choice for architectural, decorative, marine, and manufacturing applications.

- Brochure Download

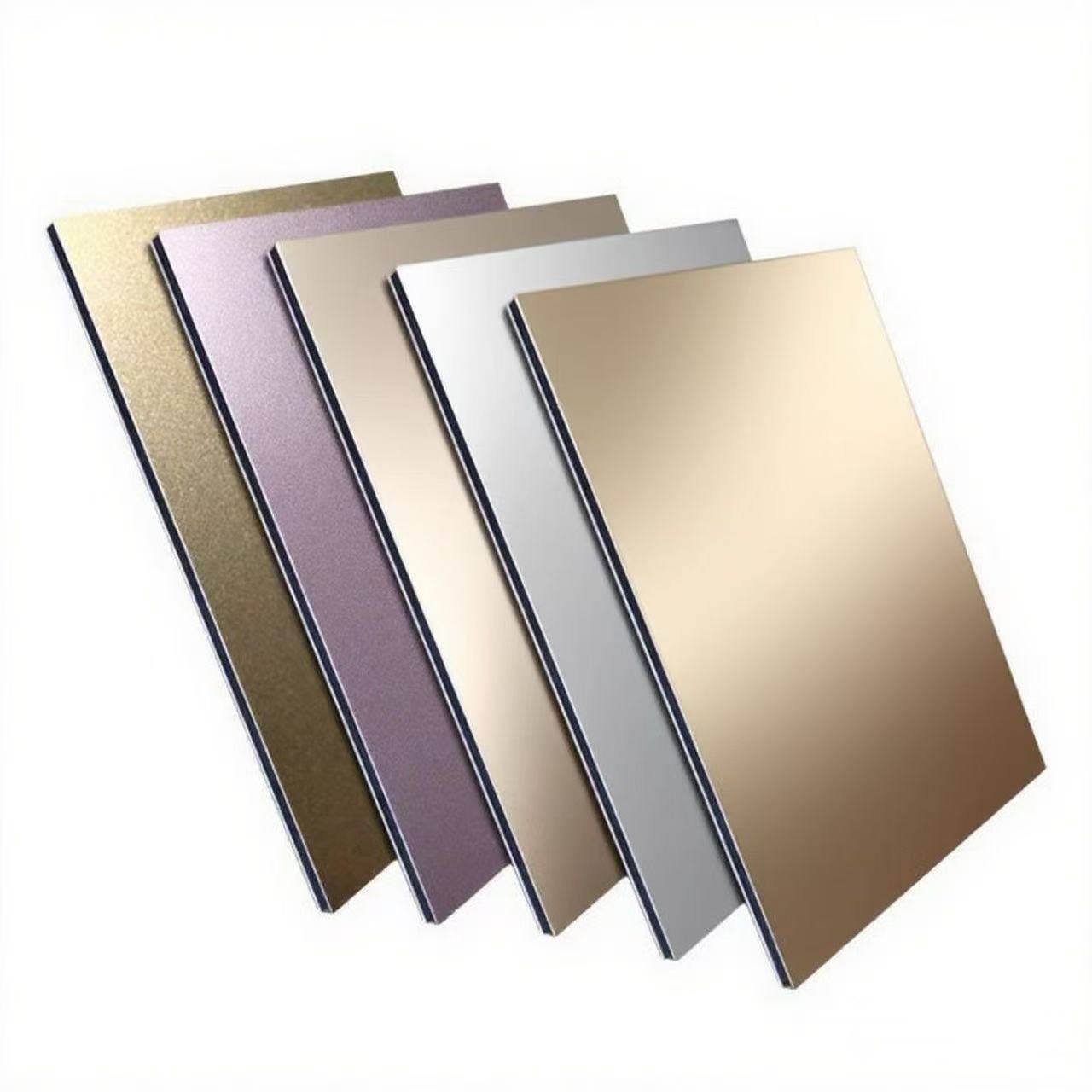

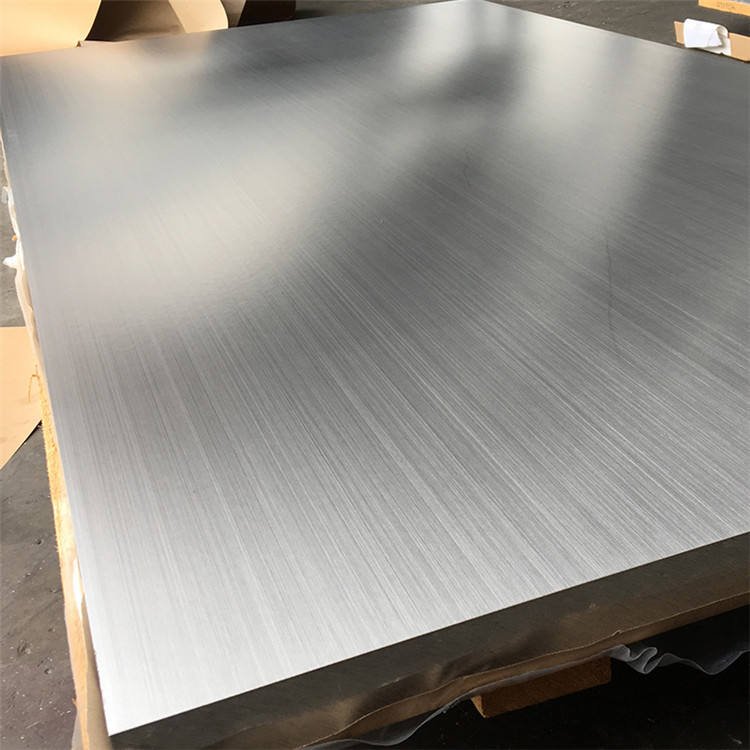

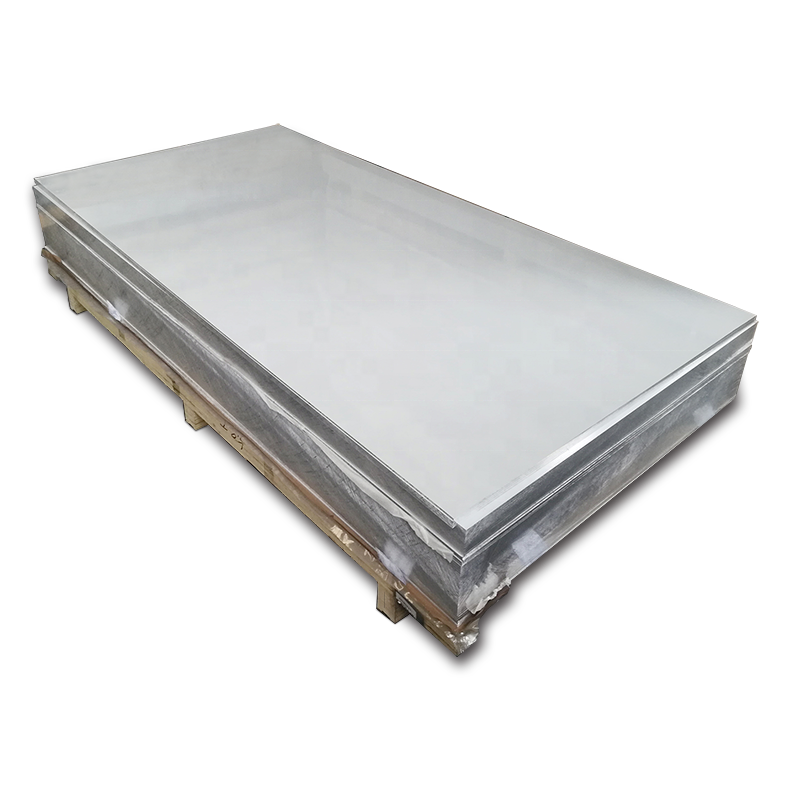

Aluminum Sheet & Plate

The aluminum sheets and plates supplied by XYC Metalworks offer an outstanding service life and superior natural resistance to corrosion. Aluminum naturally forms a protective oxide layer, making it highly resistant to weathering and various environmental factors. Its high strength, excellent formability, and significant lightweight properties ensure product reliability while saving on structural load and delivering lasting performance.

Common Grades & Properties

We specialize in the most widely used aluminum alloys:

Grade 1100 Aluminum

Composition: Commercially pure aluminum (min. 99.0%).

Properties: Excellent formability and workability, high corrosion resistance, and high thermal/electrical conductivity. It is non-heat-treatable.

Applications: Food processing equipment, chemical storage, fin stock, and decorative/architectural applications where formability is key.

Grade 3003 Aluminum

Composition: Aluminum alloyed with Manganese (approx. 1.2%).

Properties: About 20% stronger than 1100. Excellent workability and corrosion resistance. Good weldability.

Applications: The most widely used aluminum alloy. Common for cookware, fuel tanks, roofing, siding, and general sheet metal work.

Grade 5052 Aluminum

Composition: Aluminum alloyed with Magnesium (approx. 2.5%).

Properties: The highest strength of the common non-heat-treatable grades. Excellent corrosion resistance, especially in marine (saltwater) environments. Good formability and weldability.

Applications: Marine hardware, boat hulls, fuel tanks, enclosures, and architectural components in coastal areas.

Grade 6061 Aluminum

Composition: Aluminum alloyed with Magnesium and Silicon.

Properties: A heat-treatable alloy with excellent strength, good corrosion resistance, and good machinability and weldability.

Applications: The most versatile of the heat-treatable alloys. Used for structural applications, bridge components, automotive parts, and machine parts.

Sheet & Plate Specifications

| Parameter | Details |

| Alloy Grades | 1100, 3003, 5052, 6061, 5083, 7075, etc. |

| Temper | O, H14, H22, H32, H34, T4, T6, T651, etc. |

| Thickness | 0.2mm – 350mm |

| Standard Size | 1000mm x 2000mm, 1219mm x 2438mm, 1500mm x 3000mm (Custom cutting available) |

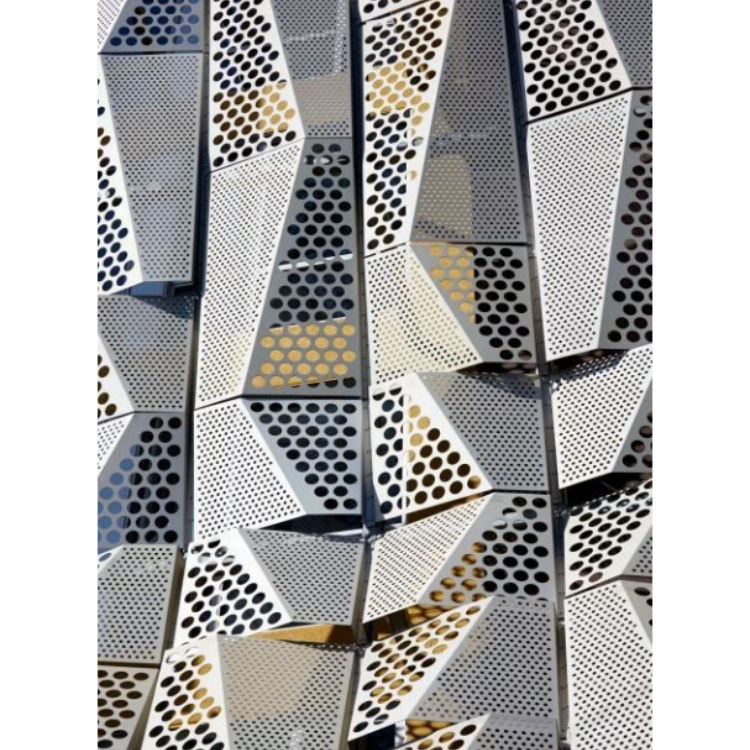

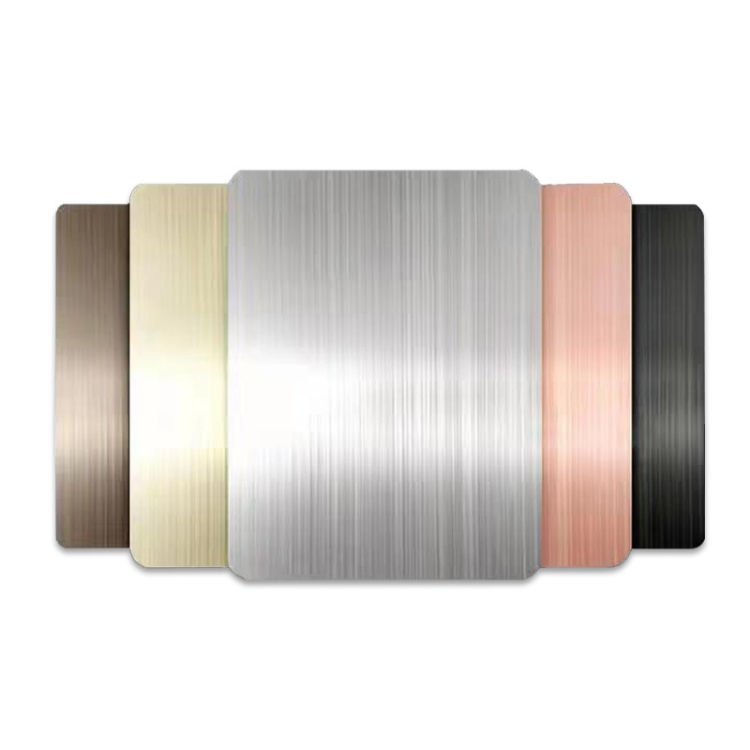

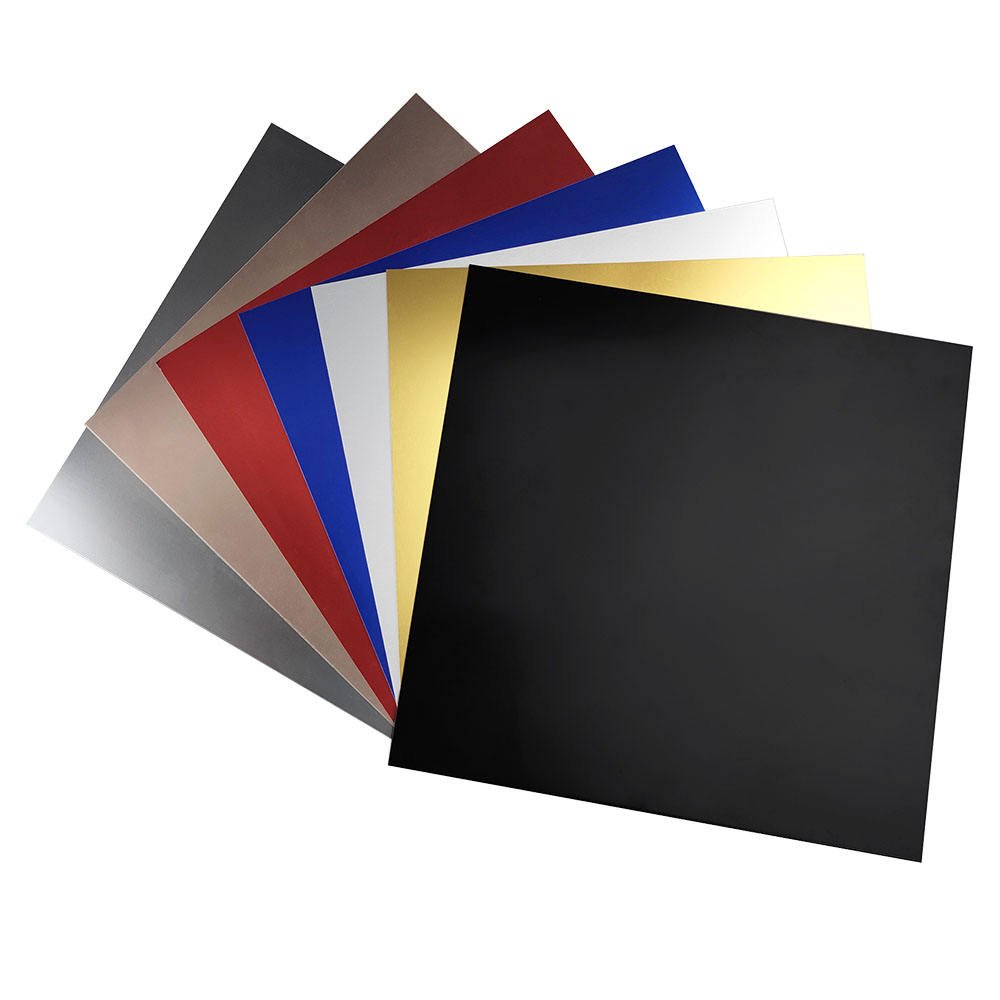

Wide Range of Surface Finishes

We offer a variety of surface treatments to meet your aesthetic and functional needs:

Mill Finish: The natural, as-rolled finish of the aluminum.

Brushed / Hairline (HL): A smooth, continuous-grain finish ideal for decorative and architectural applications.

Anodized Finish: An electrochemical process that forms a durable, protective oxide layer. It is corrosion-resistant and can be dyed in various colors (e.g., silver, black, bronze).

PVDF-Coated Finish: A high-performance liquid paint coating ideal for exterior architectural facades, offering superior weather and UV resistance.

Powder-Coated Finish: A durable, electrostatic-applied dry powder finish available in a nearly limitless range of colors.

Polished (Mirror): A highly polished, reflective surface with a strong decorative effect.

Aluminum Sheet vs. Plate

Aluminum Sheet: Typically refers to material less than 6.35mm (0.25 inches) thick. It is lighter and suitable for applications where formability and weight are key, such as architectural cladding, roofing, automotive body panels, and signage.

Aluminum Plate: Refers to material 6.35mm (0.25 inches) or thicker. It offers greater strength and is suitable for heavy-duty structural applications like boat hulls, storage tanks, and structural supports.

Aluminum Tubes

In addition to flat-rolled products, XYC Metalworks offers a wide range of aluminum tubes for structural support, fluid conveyance, and decorative applications. Our tubes are available in common alloys like 6061 and 6063, ensuring consistent and exceptional quality.

Main Types

1.Extruded (Seamless) Tube

2.Process: Manufactured by pushing a solid aluminum billet through a die, resulting in no welded seam.

Properties: Offers a smooth, seamless surface and good strength. Ideal for pressure applications and complex or custom shapes (profiles).

Standards: ASTM B221

3.Welded Tube

4.Process: Formed from an aluminum coil and joined with a longitudinal weld.

Properties: Highly efficient to produce and cost-effective. The primary choice for structural and decorative applications where high pressure tolerance is not needed.

Standards: ASTM B313, B547

Tube Specifications

Parameter | Details |

Shape | Round, Square, Rectangular, Custom Profiles |

Alloy Grade | 6061, 6063, 3003, 5052 |

Wall Thickness (WT) | 0.5mm – 20mm (depending on type) |

Length | Standard 6 meters (Custom cutting available) |

Surface | Mill Finish, Anodized, Powder Coated, Brushed |

Applications | Architectural railings, handrails, door frames, window frames, structural framing, tents, and furniture. |

Why Choose XYC Metalworks?

Superior Corrosion Resistance: Aluminum naturally generates a protective oxide coating, making it ideal for long-term use in most environments, including marine applications (5052).

Exceptional Strength-to-Weight Ratio: Aluminum offers significant strength at a fraction of the weight of steel, reducing structural load and improving handling.

Excellent Formability: Aluminum is highly malleable and can be easily formed, bent, and cut, allowing for complex custom fabrications.

Aesthetic Versatility: With finishes from anodized to PVDF-coated and polished, aluminum offers limitless possibilities for modern architecture and design.

Ease of Fabrication: Aluminum is readily welded, cut, and machined, allowing it to meet the precise needs of any custom project.

Low Maintenance & Recyclable: Aluminum is easy to clean and requires minimal upkeep. It is also 100% recyclable without any loss of quality, making it an environmentally friendly material.

Frequently Asked Questions (FAQs)

Q1: What are the primary applications for Custom Aluminum Sheets and Plates?

A: Aluminum sheets are widely used in architectural aluminum solutions like roofing and facades, while thicker plates support heavy-duty structural applications.

Q2: How do I choose between Aluminum Alloy Grades 3003 and 5052?

A: Grade 3003 is excellent for general formability. However, if your project requires higher strength or exposure to saltwater, we recommend Aluminum Alloy Grade 5052.

Q3: What makes Aluminum Alloy Grade 6061 different for fabrication?

A: Aluminum Alloy Grade 6061 is heat-treatable, offering superior strength and machinability for structural bridge components and automotive parts.

Q4: Does XYC Metalworks provide custom aluminum fabrication for tubes?

A: Yes, we offer a wide range of custom aluminum tubes (seamless and welded) in alloys like 6061 and 6063 for railings and structural framing.

Q5: What does aluminum "temper" mean in metal engineering?

A: Temper refers to the hardness and strength achieved through thermal treatment or work-hardening, such as ‘O’ (soft) or ‘T6’ (heat-treated).

Q6: Will aluminum rust in outdoor architectural projects?

A: No, aluminum does not contain iron and cannot rust. It forms a natural protective oxide layer that resists weathering and environmental factors.

Q7: What is the difference between an aluminum sheet and a plate?

A: The primary difference is thickness: material under 6.35mm is a sheet, while material 6.35mm and over is considered a plate.

Q8: Can your aluminum products be customized with specific surface finishes?

A: Absolutely. We offer various finishes including Anodized, PVDF-coated for facades, and high-gloss Mirror polishing to meet your aesthetic needs.

Q9: What is the benefit of extruded (seamless) aluminum tubes?

A: Extruded tubes offer a seamless surface and are ideal for pressure applications and complex custom aluminum fabrication shapes.

Q10: Is aluminum an environmentally friendly material for construction?

A: Yes, aluminum is 100% recyclable without losing quality. Recycling it uses only 5% of the energy needed for primary production.

Secure Your Site with Confidence

Looking for reliable, stylish, and durable bollard solutions? Contact XYC Metalworks today for specifications, finish samples, installation drawings, or a customized quote.

Industry Expertise

Our highly skilled team knows how to optimally produce the metal finish and guarantees to create a finish that is in line with your aspirations.

High-Quality Materials

We employ superior quality metals for captivating and enduring metal finishes giving architectural or interior design projects longevity.

Custom Solutions

The decorative panels can be produced in the preferred or desired hue, surface texture, and weave structure that you desire for your project.

Exceptional Service

Making customers content is always our goal, and effective communication, problem solving, and timely help guarantee a smooth project process.

Sustainable Practices

Such as using environmentally friendly materials, recycling, and reducing waste, to achieve aesthetically attractive and sustainable metal finishes.

Competitive Pricing

Our patina finish services are affordable while still providing high quality and we ensure that our prices are amongst the fairest in the market today.

Start Your Next Iconic Project

Contact our engineering team today to get a custom quote for your project or to schedule a factory tour.

Contact Form

Headquarter (China)

XYC Metalworks Co., Ltd

- No.1 Dashi Industry Zone, Lishui, Nanhai, Foshan, Guangdong, China

- +86 18923114885

- +86 18923114885

- Sales@xycmetalworks.com

- www.xycmetalworks.com