XYC Metalworks

- Lorem donec massaRated 3 out of 5

- Velit aliquet sagittisRated 3 out of 5

- Magna etiam tempor orciRated 3 out of 5

- Tristique et egestas quis ipsumRated 3 out of 5

- Cum sociis natoqueRated 3 out of 5

- Pellentesque elit eget gravidaRated 3 out of 5

Quick Summary

Rhoncus aenean vel elit scelerisque mauris pellentesque pulvinar pellentesque habitant. Ridiculus mus mauris vitae ultricies leo. Ut ornare lectus sit amet. Eu augue ut lectus arcu. Egestas quis ipsum suspendisse ultrices.

Gravida rutrum quisque non tellus orci ac. Egestas dui id ornare arcu odio ut sem nulla. Sed elementum tempus egestas sed sed risus pretium. Lectus sit amet est placerat. Consequat semper viverra nam libero justo laoreet sit amet cursus.

Specs

- Pellentesque: Gravilmusa

- Cum sociis: Natoque

- Tristiquex: Egestas quis ipsum

- Velit aliquet: Sagittis

Pros

- Phasellus vestibulum lorem

- Ridiculus mus mauris vitae

Cons

- Gravida rutrum quisque

- Egestas dui id ornare arcu

Mirror Finish

- Home

- Product Reviews

- Mirror Finish

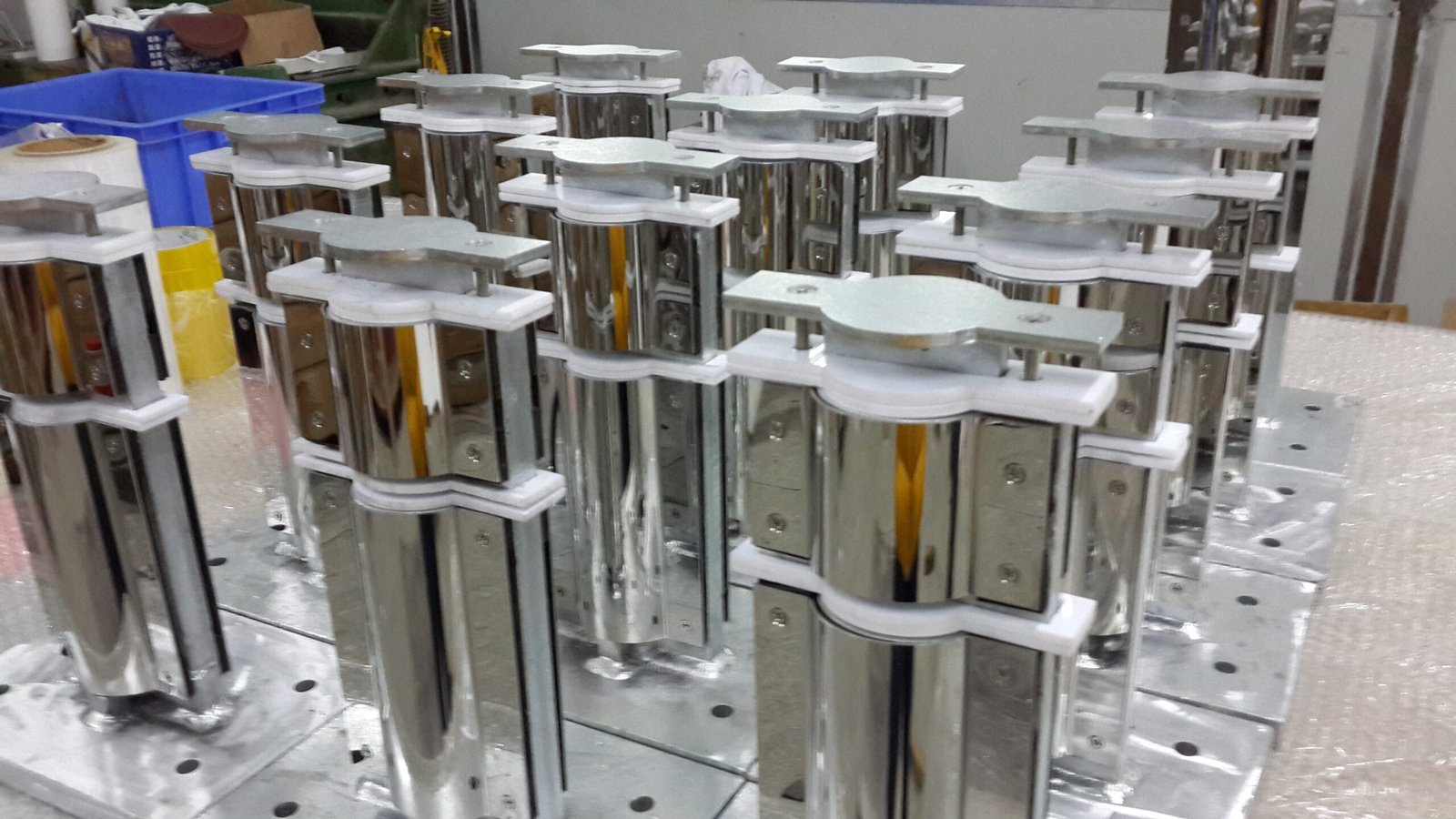

Mirror-polished stainless steel sheets—also known as No. 8 finish or 8K mirror steel—offer a stunning ultra-reflective, glass-like shine achieved through a meticulous grinding and polishing process. At XYC Metalworks, we provide premium custom stainless steel fabrication services, utilizing high-quality 304 and 316 grades to ensure high-performance durability and corrosion resistance. This pristine, high-luster finish is the preferred choice for upscale architectural cladding, interior accents, and artistic installations where elegance and light diffusion are valued.

With their brilliant luster and high reflectivity, these stainless steel sheets are a preferred choice for upscale architectural and interior applications. At XYC Metalworks, we offer premium grades like 304 and 316 to ensure long-term durability and resistance to corrosion—no matter the environment.

- Brochure Download

Key Applications

Versatile Design Potential for Modern Architecture & Industry

Mirror-polished stainless steel sheets are widely used across industries for their aesthetic appeal and structural integrity. They serve both decorative and functional purposes in a range of applications, from commercial interiors to high-end automotive finishes.

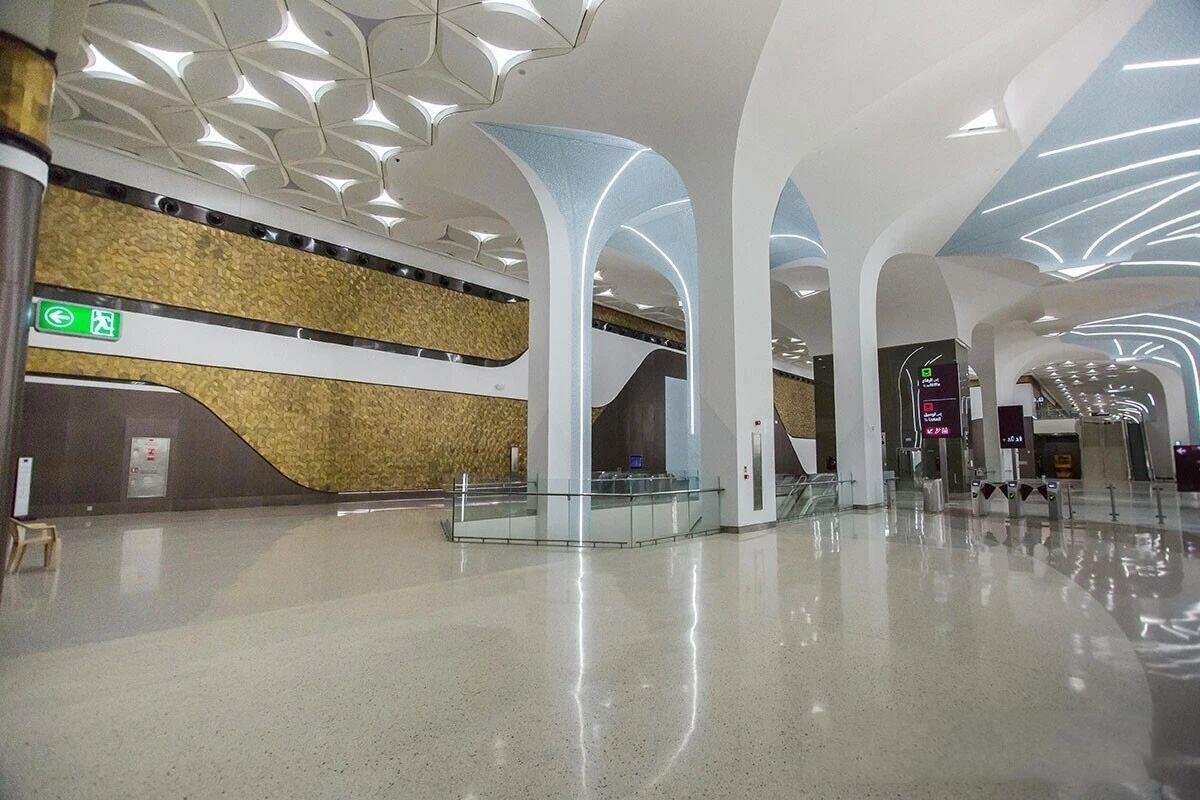

Architecture & Interior Design: Ideal for cladding walls, ceilings, columns, and partitions in residential, commercial, and hospitality environments. Their mirror effect enhances light diffusion and gives spaces a sleek, modern appearance.

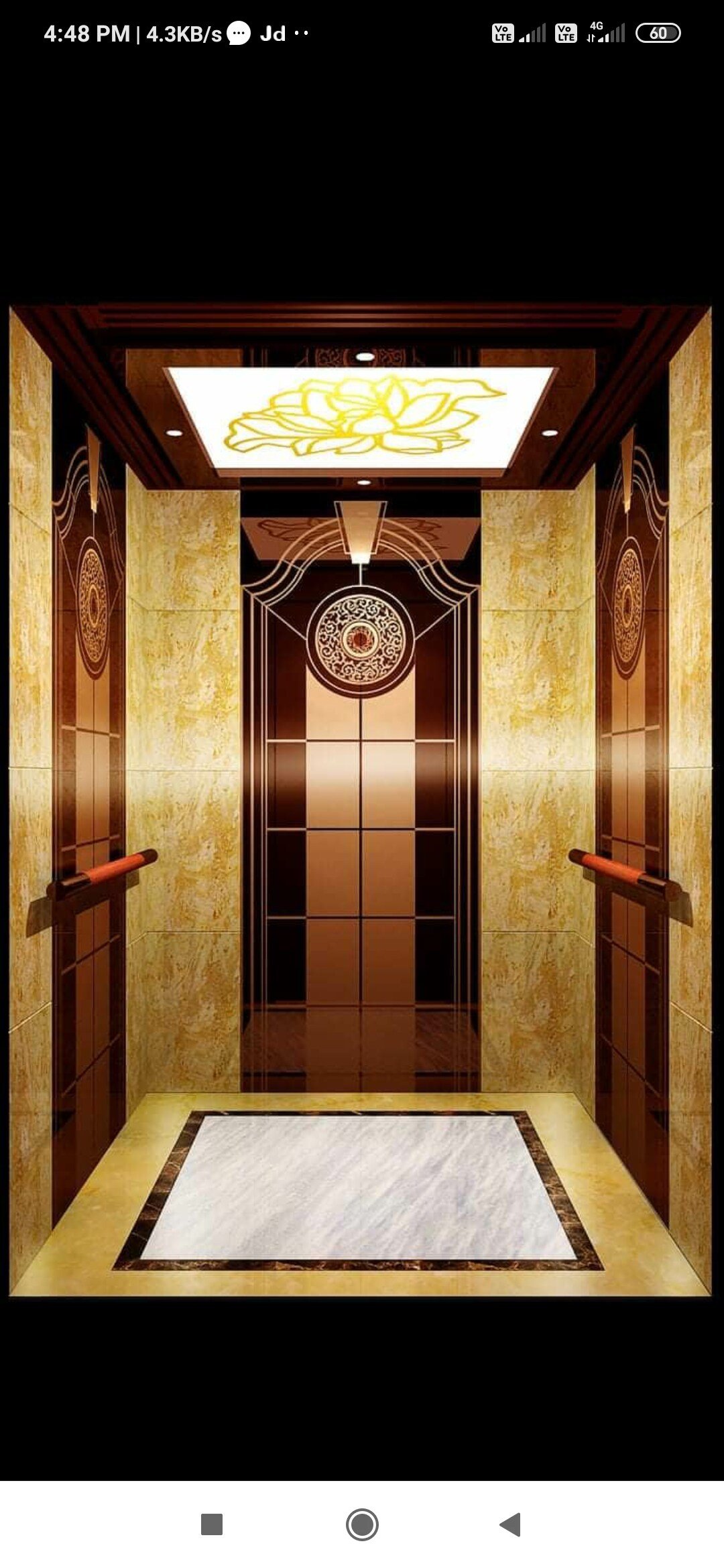

Furniture Design: Incorporating mirror stainless steel into furniture elements such as tabletops, cabinets, and countertops creates a stylish, contemporary look while offering durable surfaces that resist wear.

Retail Displays: Used extensively in luxury retail stores, mirror stainless steel enhances product visibility and adds a sense of sophistication to showcases, fixtures, and point-of-sale displays.

Automotive Components: From interior trim to decorative panels, mirror-polished stainless steel contributes to a premium feel in high-end vehicles, combining visual elegance with durable performance.

Signage & Branding: Favored by designers for high-visibility logos, signs, and brand elements in upscale commercial spaces. The polished finish projects professionalism and prestige.

Artistic Installations: Artists and sculptors use mirror-finish stainless steel for modern installations and public art, leveraging its reflective surface to interact with light and space dynamically.

Kitchen Backsplashes: Popular in residential kitchens, restaurants, and cafeterias for their hygienic surface and reflective charm. They are easy to clean and resistant to heat and moisture.

Mirror Frames & Cabinet Accents: Provides a sleek, high-gloss accent to mirror frames, shelving units, and cabinetry—enhancing both function and visual impact in modern interiors.

Technology & Electronics: Used in casings, panels, and accessories for tech products and modern appliances, thanks to its futuristic appearance and durability.

Exterior Cladding & Facades: Not only enhances a building’s visual identity but also improves energy efficiency by reflecting sunlight, contributing to passive lighting strategies in green architecture.

Product Specifications

Item | Details |

Standard | “JIS, AISI, ASTM, GB, DIN, EN” |

Thickness | 0.22 mm – 2.5 mm |

Width | “1000mm, 1219mm, 1240mm, 1250mm, 1500mm” |

Length | Custom cut (up to 6000 mm max) |

Tolerance | ±1% |

Grades | “304, 316, 201, 430, etc.” |

Technique | Cold Rolled |

Finish | “BA, 2B + No.8 Mirror Polishing, PVD Coating” |

Available Colors | “Silver, Gold, Black, Blue, Copper, Rose Gold, Champagne” |

Edges | “Mill Edge, Slit Edge” |

Applications | “Wall Panels, Ceilings, Elevators, Facades, Background Decor” |

Packing | PVC Film + Waterproof Paper + Wooden Crate |

Color Options

Enhance Design with Distinctive Hues

Mirror-finish stainless steel is available in a rich spectrum of PVD-coated colors that elevate both classic and contemporary aesthetics. From timeless silver to luxurious rose gold, and bold hues like black or blue, there’s a finish to complement every design vision. Whether you’re creating a minimalist office interior or a dramatic architectural statement, color-coated mirror sheets offer the versatility to align with your project’s branding, tone, and atmosphere.

What is Mirror Finish Stainless Steel?

Mirror finish stainless steel undergoes a precision polishing process using fine abrasives to produce a highly reflective surface with minimal grain or distortion. This No.8 finish transforms ordinary stainless steel into a brilliant, mirror-like material that enhances lighting, modernizes aesthetics, and simplifies cleaning. Due to its smooth surface and hygienic properties, it’s especially valued in kitchens, hospitality, retail, and public installations. The finish is both decorative and practical—combining form with function.

Other Polished Stainless Steel Finishes

Explore Alternative Surface Styles

In addition to the mirror finish, stainless steel can be finished in a variety of textures to suit different design requirements:

Brushed (Hairline) Finish: Subtle, linear grain for a modern industrial look.

Satin Finish: Soft, non-reflective surface ideal for understated elegance.

Vibration Finish: Dynamic, swirling texture that adds character and depth.

Each finish enhances the adaptability of stainless steel for customized designs, from luxury interiors to rugged commercial environments.

Key Benefits of Mirror-Finish Stainless Steel Sheets

✔ Elegant Visual Appeal: The mirror-like surface delivers a refined, luxurious look—perfect for premium interiors and architectural features.

✔ Versatile Design Integration: Adapts to a wide range of styles, from sleek modernism to classical detailing, and works harmoniously with glass, wood, stone, or lighting effects.

✔ Exceptional Durability: Engineered from corrosion-resistant stainless steel grades such as 304 and 316, ideal for demanding indoor and outdoor environments.

✔ Wide Applicability: Used in architecture, furniture, kitchens, elevators, electronics, signage, and more—thanks to its unique blend of beauty and function.

✔ Long-Lasting Performance: The high-gloss finish resists oxidation, staining, and scratching (when handled properly), ensuring it maintains its shine for years.

✔ Easy to Maintain: Smooth, non-porous surface allows for effortless cleaning with mild detergents—ideal for hygienic or high-traffic spaces.

✔ Enhances Lighting: The reflective surface amplifies both natural and artificial light, improving ambiance and visual depth in enclosed environments.

✔ Fully Customizable: Available in multiple thicknesses, grades, finishes, and colors to suit bespoke design specifications or industrial performance criteria.

Maintenance Tips

How to Maintain Mirror-Finish Stainless Steel Surfaces

To preserve the brilliance and integrity of mirror-polished stainless steel, follow these best practices:

Clean Regularly: Use a soft microfiber cloth with warm water or mild soap. Avoid harsh chemicals or abrasive sponges.

Prevent Scratches: Handle with care; avoid contact with sharp or gritty objects.

Dry Immediately: After cleaning, wipe surfaces dry to prevent water spots or streaks.

Polish Occasionally: Use a non-abrasive stainless steel polish to refresh the shine when needed.

Avoid Chlorides: Rinse off any contact with salt or chlorine-based cleaners to prevent tarnishing.

Storage & Transport: Use protective layers when storing or moving sheets to avoid surface damage.

Anti-Fingerprint Coating: Apply a protective wax or coating to reduce visible smudges on high-touch areas.

Stubborn Stains: Treat gently with a baking soda paste; rinse thoroughly and dry completely.

FAQs

Q1: What is mirror-polished stainless steel?

A: A: It is stainless steel polished to a No. 8 grade, resulting in a smooth, highly reflective, glass-like surface ideal for both decorative and functional applications.

Q2: How is the No. 8 mirror finish achieved?

A: The finish is achieved through progressive polishing using ultra-fine abrasives to eliminate surface defects, producing a high-luster, distortion-free reflective surface.

Q3: Is mirror-polished stainless steel durable?

A: Yes. It offers excellent resistance to corrosion, tarnishing, and wear, especially when fabricated from high-quality 304 or 316 grades.

Q4: Where is mirror-finish stainless steel commonly used?

A: It is widely used in architecture, interior décor (ceilings, walls), luxury furniture, retail displays, elevator interiors, and artistic installations.

Q5: How should I clean and maintain mirror stainless steel?

A: Gently clean with a soft microfiber cloth and warm water or mild soap. Avoid abrasive sponges and harsh chemicals to prevent scratching the high-gloss surface.

Q6: Can I customize the color of mirror-polished sheets?

A: Absolutely. Using advanced PVD coating, XYC Metalworks offers a rich spectrum of colors including Gold, Rose Gold, Black, Blue, Copper, and Champagne.

Q7: Does mirror stainless steel help with interior lighting?

A: Yes, its highly reflective surface amplifies both natural and artificial light, improving ambiance and adding visual depth to enclosed environments.

Q8: Can mirror-polished stainless steel be used for exterior cladding?

A: Yes. It enhances a building’s visual identity and can improve energy efficiency by reflecting sunlight, contributing to green architectural strategies.

Q9: What is the difference between 304 and 316 mirror steel?

A: While both are durable, 316 grade contains molybdenum for enhanced protection in harsh, coastal, or marine environments.

Q10: Are other finishes available if I don't want a mirror effect?

A: Yes. XYC Metalworks also provides brushed (hairline), satin, and vibration finishes to complement different design requirements.

Need help choosing the right mirror-polished stainless steel for your next project?

Contact XYC Metalworks for expert consultation, samples, or custom fabrication support.

Industry Expertise

Our highly skilled team knows how to optimally produce the metal finish and guarantees to create a finish that is in line with your aspirations.

High-Quality Materials

We employ superior quality metals for captivating and enduring metal finishes giving architectural or interior design projects longevity.

Custom Solutions

The decorative panels can be produced in the preferred or desired hue, surface texture, and weave structure that you desire for your project.

Exceptional Service

Making customers content is always our goal, and effective communication, problem solving, and timely help guarantee a smooth project process.

Sustainable Practices

Such as using environmentally friendly materials, recycling, and reducing waste, to achieve aesthetically attractive and sustainable metal finishes.

Competitive Pricing

Our patina finish services are affordable while still providing high quality and we ensure that our prices are amongst the fairest in the market today.

Start Your Next Iconic Project

Contact our engineering team today to get a custom quote for your project or to schedule a factory tour.

Contact Form

Headquarter (China)

XYC Metalworks Co., Ltd

- No.1 Dashi Industry Zone, Lishui, Nanhai, Foshan, Guangdong, China

- +86 18923114885

- +86 18923114885

- Sales@xycmetalworks.com

- www.xycmetalworks.com