XYC Metalworks

- Lorem donec massaRated 3 out of 5

- Velit aliquet sagittisRated 3 out of 5

- Magna etiam tempor orciRated 3 out of 5

- Tristique et egestas quis ipsumRated 3 out of 5

- Cum sociis natoqueRated 3 out of 5

- Pellentesque elit eget gravidaRated 3 out of 5

Quick Summary

Rhoncus aenean vel elit scelerisque mauris pellentesque pulvinar pellentesque habitant. Ridiculus mus mauris vitae ultricies leo. Ut ornare lectus sit amet. Eu augue ut lectus arcu. Egestas quis ipsum suspendisse ultrices.

Gravida rutrum quisque non tellus orci ac. Egestas dui id ornare arcu odio ut sem nulla. Sed elementum tempus egestas sed sed risus pretium. Lectus sit amet est placerat. Consequat semper viverra nam libero justo laoreet sit amet cursus.

Specs

- Pellentesque: Gravilmusa

- Cum sociis: Natoque

- Tristiquex: Egestas quis ipsum

- Velit aliquet: Sagittis

Pros

- Phasellus vestibulum lorem

- Ridiculus mus mauris vitae

Cons

- Gravida rutrum quisque

- Egestas dui id ornare arcu

Anodized

- Home

- Product Reviews

- Anodized

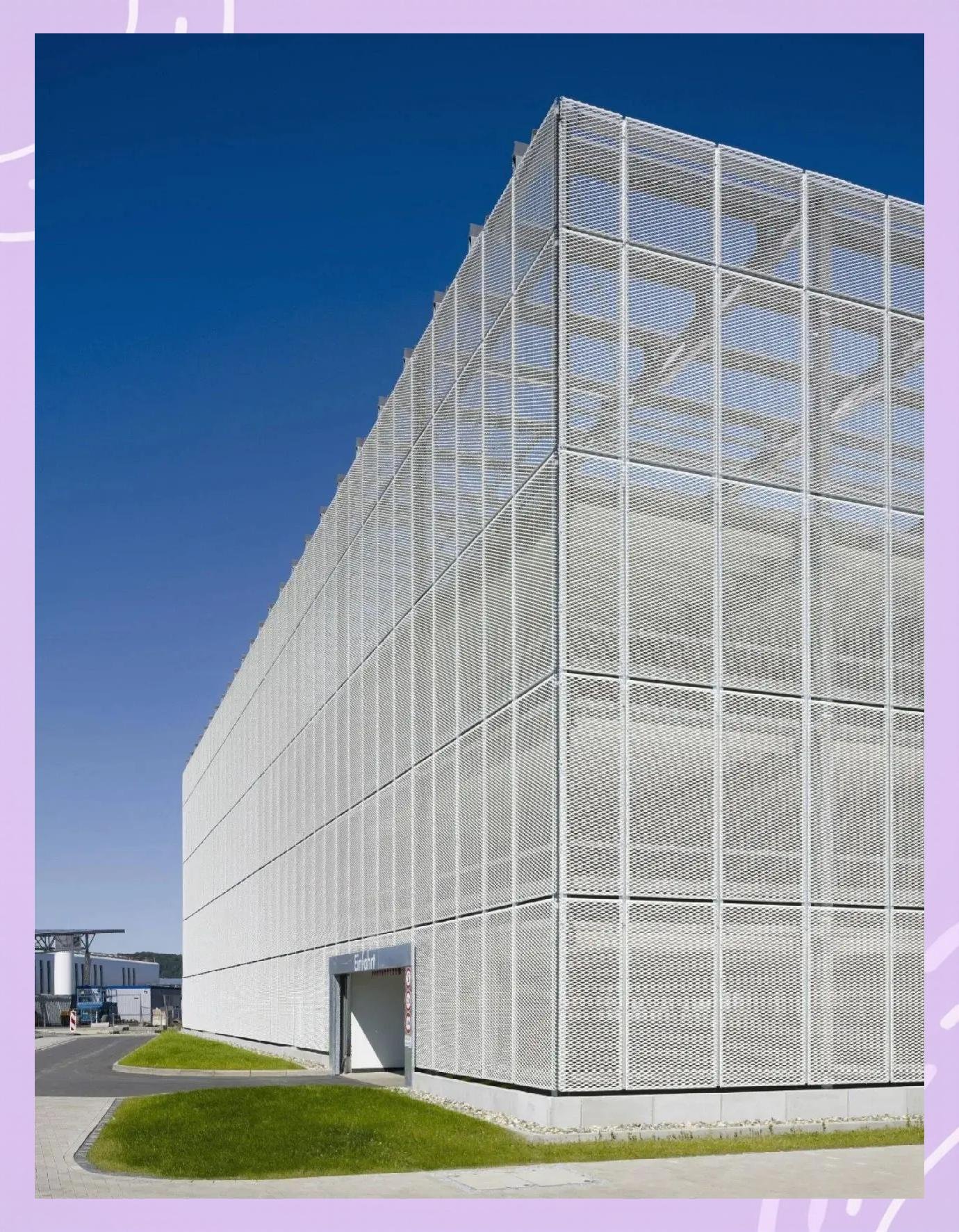

Anodized Aluminium Sheet Metal from XYC Metalworks combines aesthetic brilliance with industrial-grade durability. Precision-engineered and chemically treated through an advanced electrochemical process, our sheets feature a hardened, vibrant metallic finish that is ideal for architectural façades, electronics enclosures, and automotive trim. Whether you require Architectural Aluminium Cladding for coastal projects or high-performance components for industrial use, our Anodized Aluminium Solutions provide unmatched protection and design flexibility.

Whether you’re designing sleek building façades or high-performance enclosures, anodized aluminium adds both protection and design flexibility. Its elegant finish and low-maintenance surface make it a smart, cost-effective choice for projects where beauty and performance must last.

- Brochure Download

Key Applications

Versatile Use Across Industries

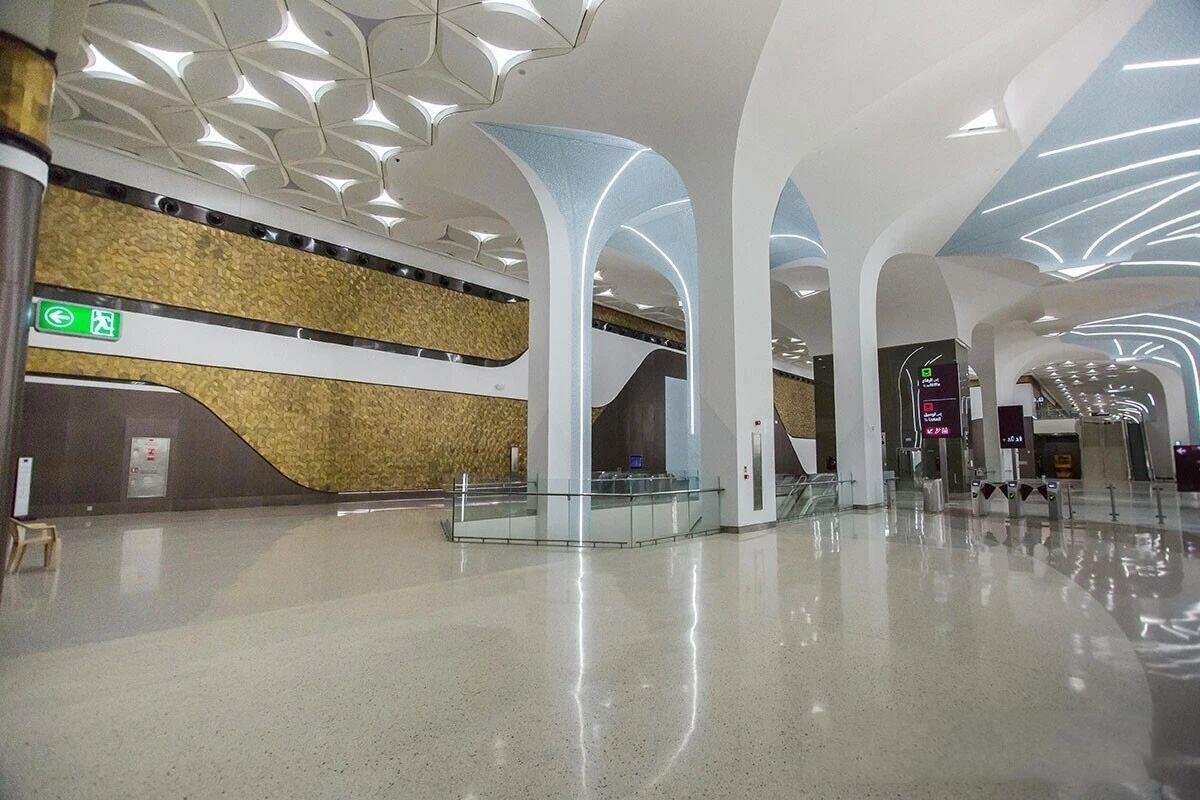

Architectural Cladding & Finishes

Anodized aluminium enhances building exteriors with a modern aesthetic and long-term weather resistance. Its fade-proof finish and robust performance make it perfect for façades, curtain walls, ceilings, and column wraps.

Electronics Enclosures

The insulating properties and surface hardness of anodized aluminium make it ideal for protecting sensitive components. Its sleek appearance adds sophistication to consumer electronics, control boxes, and precision instruments.

Automotive Trim & Interior Panels

Lightweight, corrosion-resistant, and visually striking, anodized aluminium is a favorite for automotive interior accents, gear trims, dashboard panels, and exterior decorative elements.

Signage & Branding Displays

High visibility meets high durability. Anodized aluminium is widely used for outdoor signs, plaques, and brand displays thanks to its resistance to fading, corrosion, and environmental damage.

Industrial Machinery & Equipment Panels

In demanding environments, anodized aluminium excels. Its hard surface layer resists abrasion and chemicals, making it suitable for machine covers, control panels, and protective housings.

Aerospace Components

Used in aircraft panels, housings, and fasteners, anodized aluminium delivers a crucial balance of lightweight strength and oxidation resistance, ensuring reliability under extreme conditions.

Solar Panel Frames

Its weatherproof and UV-resistant properties make anodized aluminium ideal for solar PV framing systems, offering long-term stability with minimal weight.

Interior Design Features

From decorative ceiling panels to contemporary furniture cladding, anodized aluminium brings metallic luster and durability into interior applications with timeless appeal.

Marine Applications

Anodized aluminium is highly resistant to saltwater corrosion, making it suitable for boat fittings, marine enclosures, and coastal architectural elements.

Specifications

Parameter | Value |

Standards | GB/T 24001-2016, GB/T 19001-2016, ASTM, JIS, EN |

Thickness | 0.2 mm – 3.0 mm |

Width | 30 mm – 1850 mm (Customizable) |

Length | 1220 mm – 3000 mm (Customizable) |

Tolerance | ±1% |

Alloys | 1050, 1060, 1100, 3003, 3105, 5052 |

Processing | Cold Rolled |

Finish | Anodized |

Available Colors | Silver, Champagne, Gold, Rose Gold, Black, Blue, and more |

Edge Options | Mill Edge, Slit Edge |

Applications | Ceiling, Wall Panel, Furniture, Interior Decoration |

Packaging | PVC Film + Waterproof Paper + Wooden Case |

Color Range & Aesthetic Options

Vivid. Stable. Eco-Friendly.

Anodized aluminium maintains its metallic character while offering a broad color palette. Unlike painted surfaces, anodizing embeds color into the oxide layer — ensuring it won’t peel or flake.

Available in silver, black, gold, champagne, blue, and custom tones, it brings color versatility with industrial-grade toughness.

Scratch-Resistant & UV-Stable

No Hazardous Byproducts

Colorfast & Uniform Finish

Materials Suitable for Anodizing

While anodizing is most common with aluminium, it can also be applied to:

Aluminium: The primary and most effective substrate.

Titanium: Enhances corrosion resistance and allows for brilliant color effects.

Magnesium: Improves resistance to corrosion; limited use.

Niobium & Tantalum: For decorative and high-purity industrial uses.

Zinc: Occasionally anodized for corrosion control and appearance.

Each metal type may require adjustments in electrolyte composition, temperature, or voltage during processing.

Commercial Benefits of Anodized Aluminium

Corrosion Resistance

The anodized oxide layer offers superior resistance to moisture, chemicals, and UV exposure — making it ideal for outdoor and industrial environments.

Design Flexibility

Choose from a wide spectrum of colors and finishes to meet specific branding or aesthetic requirements without compromising on function.

Durability in Harsh Conditions

Anodized aluminium withstands extreme temperatures, abrasion, and chemical exposure — delivering performance in aerospace, marine, and manufacturing sectors.

Lightweight Performance

At nearly one-third the weight of stainless steel, aluminium reduces structural loads while maintaining strength — crucial for automotive and aerospace industries.

Environmentally Friendly

The anodizing process is non-toxic, produces no hazardous waste, and does not use heavy metals, making it safe and sustainable.

Low Maintenance

With its non-porous surface, anodized aluminium resists fingerprints, dirt, and stains, requiring minimal cleaning over time.

Enhanced Surface Hardness

The hardened surface improves wear resistance and surface integrity, extending product lifespan.

Electrical Insulation

Anodized aluminium naturally insulates against electricity, which is advantageous in electrical enclosures and electronic device components.

Frequently Asked Questions (FAQs)

Q1: What is Anodized Aluminium Sheet Metal and how is it made?

A: It is aluminum that has undergone an electrochemical process to form a protective, integrated oxide layer. Unlike paint, this layer is embedded in the metal, ensuring it won’t peel, flake, or chip.

Q2: Why is anodizing preferred for Architectural Aluminium Cladding in coastal cities like Hong Kong?

A: The anodized layer offers superior resistance to saltwater corrosion and humidity. It maintains its integrity in harsh marine environments with minimal wear or fading.

Q3: Can I customize the color of my Anodized Aluminium Sheet Metal?

A: Yes. We offer a broad palette including Silver, Gold, Champagne, and Black in both matte and gloss finishes to meet your specific branding or design needs.

Q4: Is the color of colored aluminium stable under UV exposure?

A: Absolutely. Our anodizing process creates UV-stable finishes that are highly resistant to fading, making them perfect for high-visibility outdoor signage and building façades.

Q5: Does anodized aluminium provide electrical insulation?

A: Yes. The anodized oxide layer is non-conductive, providing natural electrical insulation which is ideal for electronics enclosures and sensitive device components.

Q6: How does the weight of anodized aluminium compare to stainless steel?

A: Anodized aluminium is nearly one-third the weight of stainless steel. This significantly reduces structural loads on buildings while maintaining high strength.

Q7: Is the anodizing process environmentally friendly?

A: Yes, it is a sustainable material choice. The process is non-toxic, produces no hazardous waste, uses no heavy metals, and the final product is 100% recyclable.

Q8: What is the surface hardness of Anodized Aluminium Sheet Metal?

A: The electrochemical process creates a hardened surface that significantly improves wear and abrasion resistance, extending the product’s lifespan in demanding industrial environments.

Q9: How do I clean and maintain anodized surfaces?

A: Maintenance is minimal. The non-porous surface resists fingerprints and dirt; simply use a soft cloth and mild detergent to keep the finish looking new.

Q10: What industries benefit most from Anodized Aluminium Solutions?

A: Due to its versatility, it is widely used in aerospace, marine construction, automotive accents, consumer electronics, and modern architectural design .

Let’s Build Something Brilliant

Need anodized aluminium sheet solutions for your next project? From custom sizes to exclusive colors and tailored finishes, XYC Metalworks offers unmatched expertise and production capacity.

📩 Contact us today to get a quote or request a sample

Industry Expertise

Our highly skilled team knows how to optimally produce the metal finish and guarantees to create a finish that is in line with your aspirations.

High-Quality Materials

We employ superior quality metals for captivating and enduring metal finishes giving architectural or interior design projects longevity.

Custom Solutions

The decorative panels can be produced in the preferred or desired hue, surface texture, and weave structure that you desire for your project.

Exceptional Service

Making customers content is always our goal, and effective communication, problem solving, and timely help guarantee a smooth project process.

Sustainable Practices

Such as using environmentally friendly materials, recycling, and reducing waste, to achieve aesthetically attractive and sustainable metal finishes.

Competitive Pricing

Our patina finish services are affordable while still providing high quality and we ensure that our prices are amongst the fairest in the market today.

Start Your Next Iconic Project

Contact our engineering team today to get a custom quote for your project or to schedule a factory tour.

Contact Form

Headquarter (China)

XYC Metalworks Co., Ltd

- No.1 Dashi Industry Zone, Lishui, Nanhai, Foshan, Guangdong, China

- +86 18923114885

- +86 18923114885

- Sales@xycmetalworks.com

- www.xycmetalworks.com