XYC Metalworks

An Architect’s Guide to PVD Coating: Why It’s the Superior Finish for High-Traffic Luxury Spaces

- Home

- Insights

- Technical & Material Guides

- An Architect’s Guide to PVD Coating: Why It’s the Superior Finish for High-Traffic Luxury Spaces

Table of Contents

In high-traffic luxury spaces—hotel lobbies, retail flagships, transportation hubs—architects face a critical challenge: a finish must be stunning, but it must also be tough. Traditional finishes often force a compromise between aesthetics and durability. PVD coating eleganty solves this, offering a robust, long-lasting surface that achieves the highest level of aesthetic refinement. It is not just a coating; it is a permanent fusion of color and resilience.

What is PVD Coating? (And Why is it Different?)

PVD stands for Physical Vapor Deposition. It is a high-tech finishing process conducted in a high-vacuum chamber.

Unlike traditional electroplating or painting, which simply “sit on” the base metal, PVD is a molecular bond. A solid target material (like titanium or zirconium) is vaporized into a plasma and then precisely deposited onto the stainless steel substrate.

The result? The finish isn’t a layer on the steel; it becomes part of the steel’s surface. This atomic-level bond is the secret to its superior performance.

Beyond Paint & Plating: Why PVD is the Superior Choice

For specifiers, the choice of finish impacts the project’s long-term success. PVD consistently outperforms older methods:

PVD vs. Paint/Powder Coating: Paint is a liquid application that can chip, peel, and fade. PVD is a bonded metal finish that retains the true metallic luster of the underlying brushed or mirrored steel and is exceptionally resistant to chipping.

PVD vs. Electroplating: Electroplating involves a chemical bath with significant environmental concerns. PVD is a dry, environmentally-friendly “Green” process. More importantly, PVD finishes are demonstrably harder, more scratch-resistant, and provide far greater corrosion resistance.

The Architect’s Dual Advantage: Aesthetic Freedom & “High-Traffic” Durability

PVD delivers on the two promises most critical to architects:

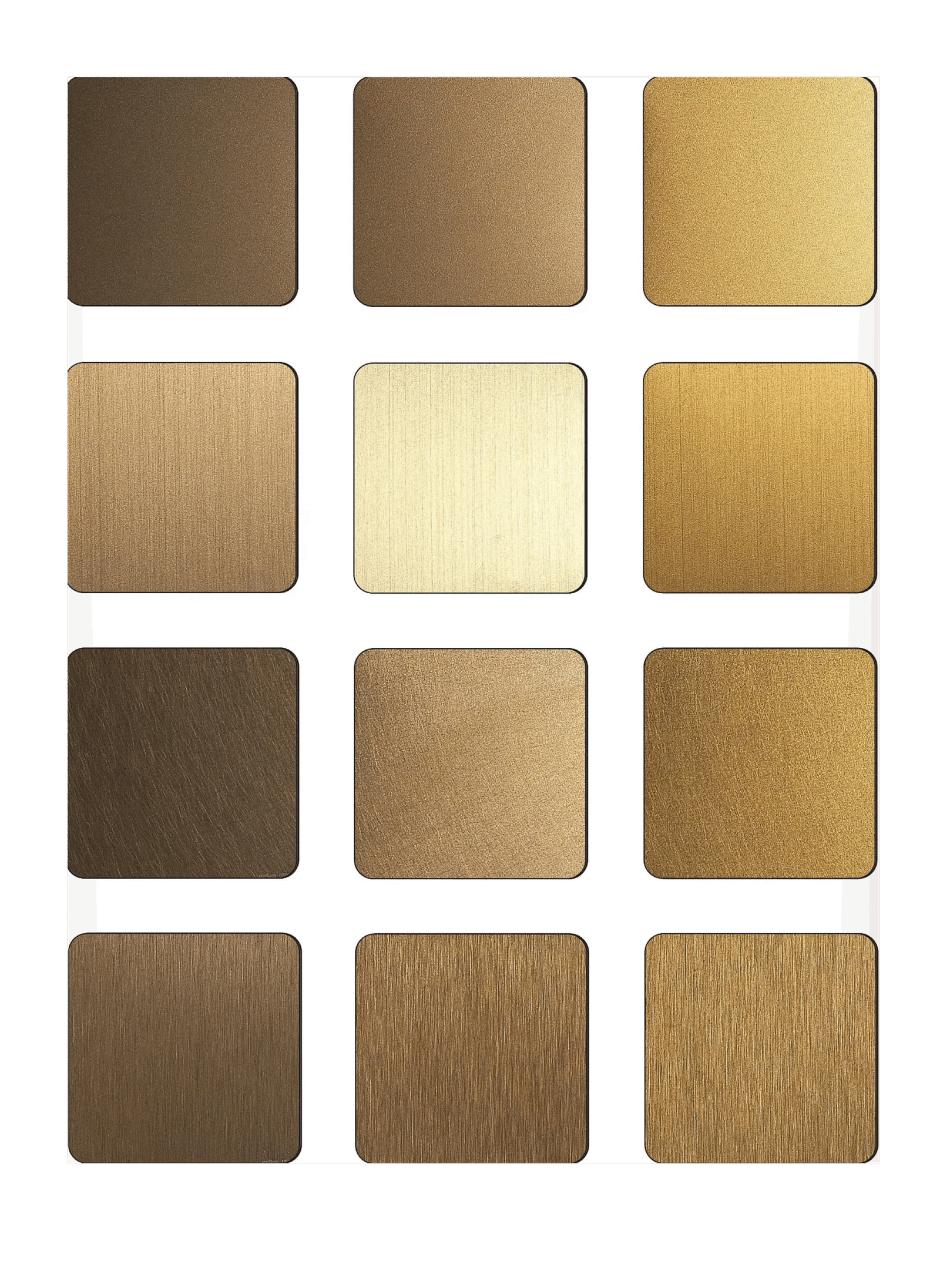

1.The “Luxury”: A Limitless Aesthetic PaletteThe PVD process allows for a vast range of colors and textures without compromising the integrity of the metal. At XYC Metalworks, we can apply PVD finishes to a wide array of base textures:

Classic Finishes: From timeless Gold, Rose Gold, and Bronze to contemporary Black and Champagne.

Base Textures: The color can be applied over any stainless steel finish, including Brushed (Hairline), Satin, Mirror Polished, or Matte (Bead-blasted).

2. The “High-Traffic”: Unmatched Durability This is where PVD truly shines in commercial applications. The finish is:

Abrasion & Scratch Resistant: Up to 10 times harder than traditional finishes.

Corrosion & Chemical Resistant: Ideal for high-touch areas (handrails, elevator doors) and harsh environments.

UV Resistant: The color will not fade over time, even in direct sunlight, making it suitable for exterior facades.

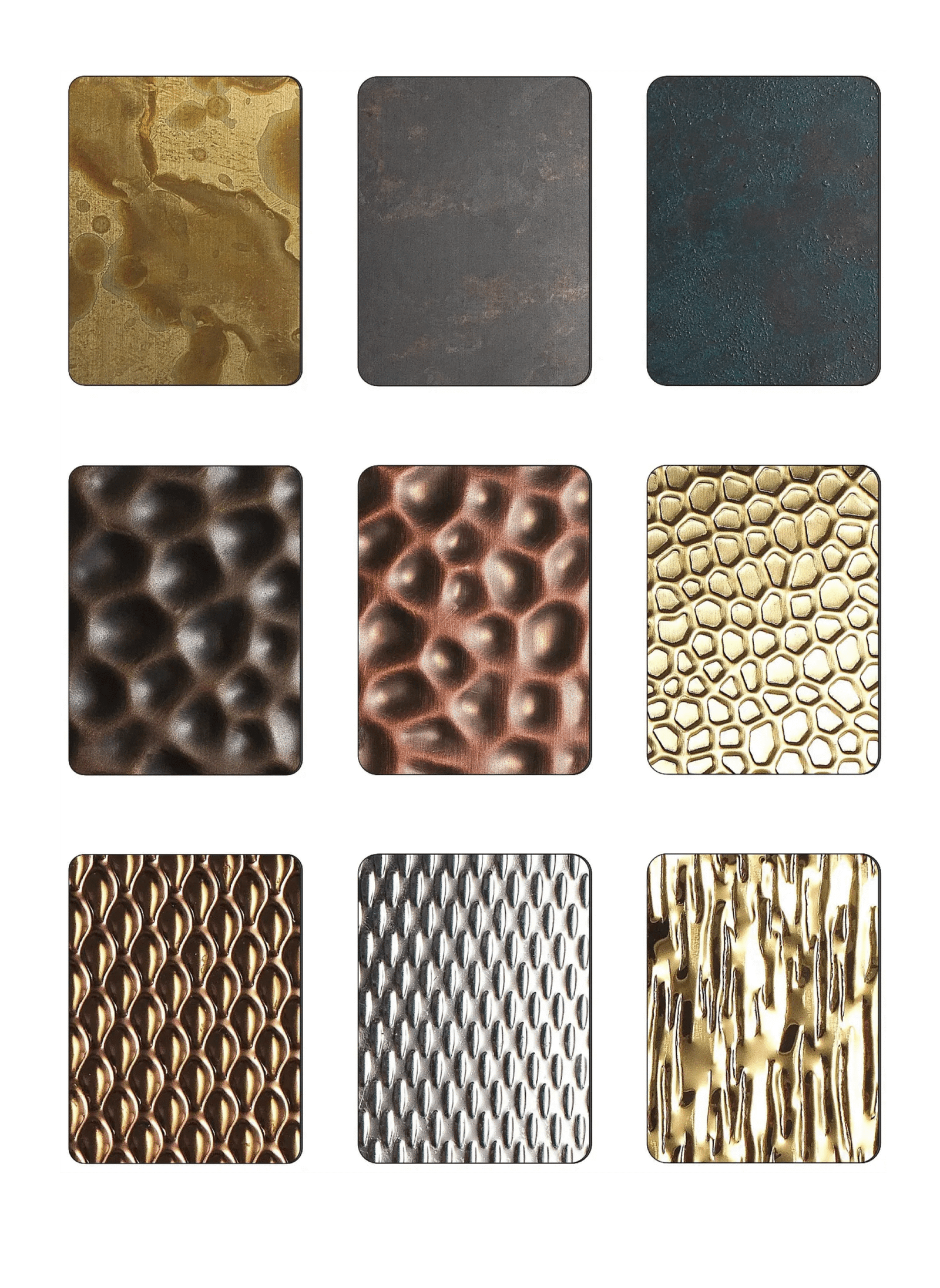

Beyond the Basics: PVD on Specialty Finishes

As premier fabrication partners, our expertise goes further. PVD is not limited to flat, smooth sheets. We can combine this durable coating with complex, artistic surfaces—a capability that opens new doors for visionary design. This includes applying PVD coatings to:

Embossed & Hammered Sheets

Antique & Patina Finishes

Laser-Cut & Etched Patterns

This combination of texture and durable color allows architects to create truly unique, hard-wearing surfaces that were previously impossible to achieve.

Conclusion: PVD coating is no longer an “either/or” choice between beauty and strength; it is a “both/and” solution. It empowers architects to specify bold metallic colors for the most demanding environments, confident that the finish will endure. For your next landmark project, consider the permanent, proven solution.

Search

Recent Comments

Recent Posts

- An Architect’s Guide to PVD Coating: Why It’s the Superior Finish for High-Traffic Luxury Spaces November 21, 2025

- From 0 to 50,000+: The Quality Control & Mass Production of 3D Gold Panels for the Doha Metro November 21, 2025

- From Mock-up to Masterpiece: A Case Study in Precision Metalwork for the NBK HQ November 21, 2025

- More Than a Cover: How Column Cladding is Redefining Commercial Lobbies November 21, 2025

- Why We Build it Twice: The Critical Role of the 1:1 Mock-up in Our Process November 21, 2025