XYC Metalworks

Finishes

- Home

- Finishes

Discover the perfect harmony of durability and design with XYC Metalworks’ advanced sheet metal surface finishes. Whether you’re working with stainless steel or aluminium, our expertly crafted finishes are engineered to enhance both aesthetics and functionality—providing long-lasting performance without visible deterioration for decades.

Explore the full potential of stainless steel and aluminium with our diverse range of surface finishes. From contemporary elegance to classic textures, each finish offers visual distinction alongside exceptional corrosion resistance and environmental durability.

- Brochure Download

Surface Finish Categories

Explore Our Range of Styles Sheet metal finishes serve not only as decorative elements but also as functional enhancements. Each finish type brings unique visual effects and performance advantages—from improved aesthetics and surface protection to extended longevity.

However, finishes vary in cost, functionality, and characteristics, so choosing the right finish depends on your specific project requirements.

Popular Sheet Metal Finishes

Hairline Finish A refined linear texture featuring directional brush strokes that enhance the surface with a sleek, professional look. This finish effectively masks scratches and is ideal for high-traffic commercial and architectural applications.

Sandblasted Finish Achieve a matte, tactile texture through fine abrasive blasting. This industrial-inspired finish offers subtle depth and is perfect for minimalist, modern, and urban-themed designs.

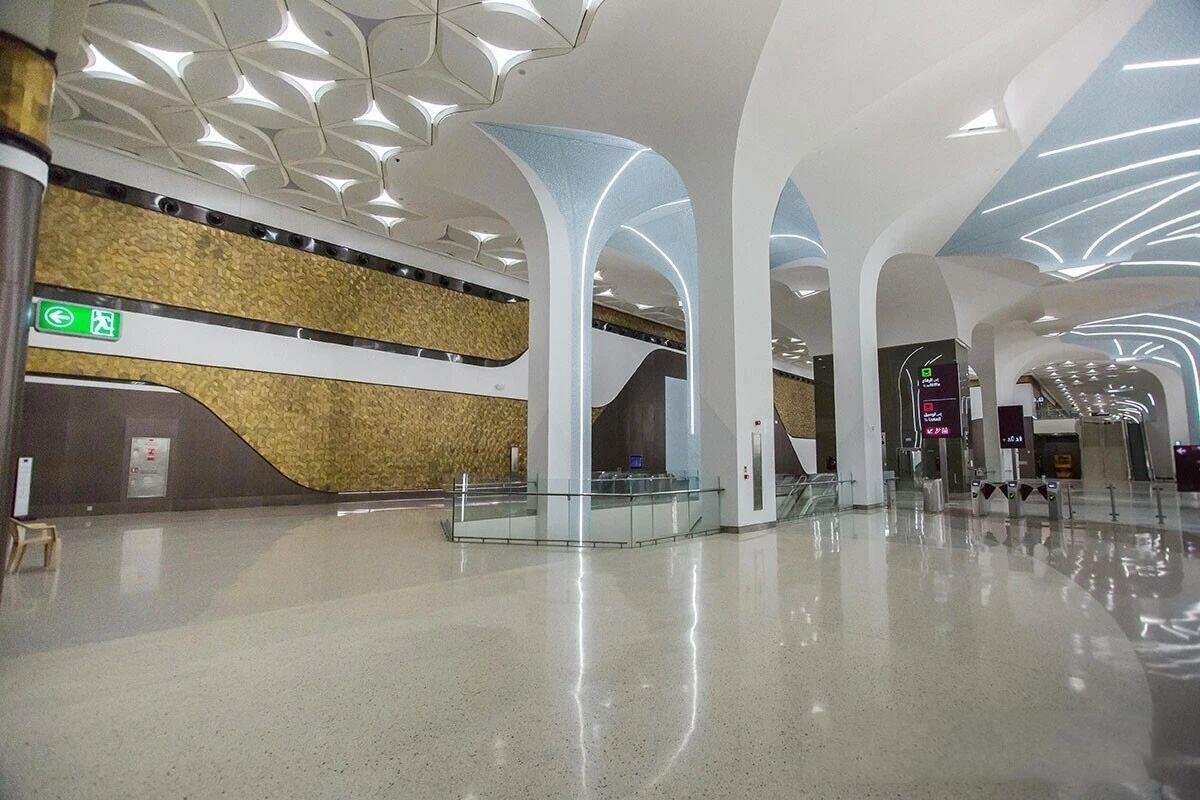

Mirror Finish Create a highly reflective, polished surface that delivers maximum visual impact. Mirror finishes add luxury and sophistication, commonly used in high-end architecture, elevators, and decorative panels.

Satin Finish Balanced between gloss and matte, satin finishes deliver a smooth, even appearance. With excellent resistance to smudges and scratches, it’s a versatile choice for interiors, appliances, and architectural facades.

Vibration Finish A non-directional swirl pattern that introduces artistic movement and a unique character to metal surfaces. Ideal for contemporary and avant-garde architectural designs seeking a bold statement.

Patina Finish Introduce artistic heritage and timeless character with a patina finish. This oxidized surface adds color variation and vintage appeal, often used in feature walls, signage, and bespoke décor elements.

Liquid Metal (Bonded Metal) Finish A cutting-edge solution that applies a bonded liquid metal layer over a base material, offering the appearance of solid cast metal with lightweight advantages. Perfect for luxury interiors and premium exterior cladding.

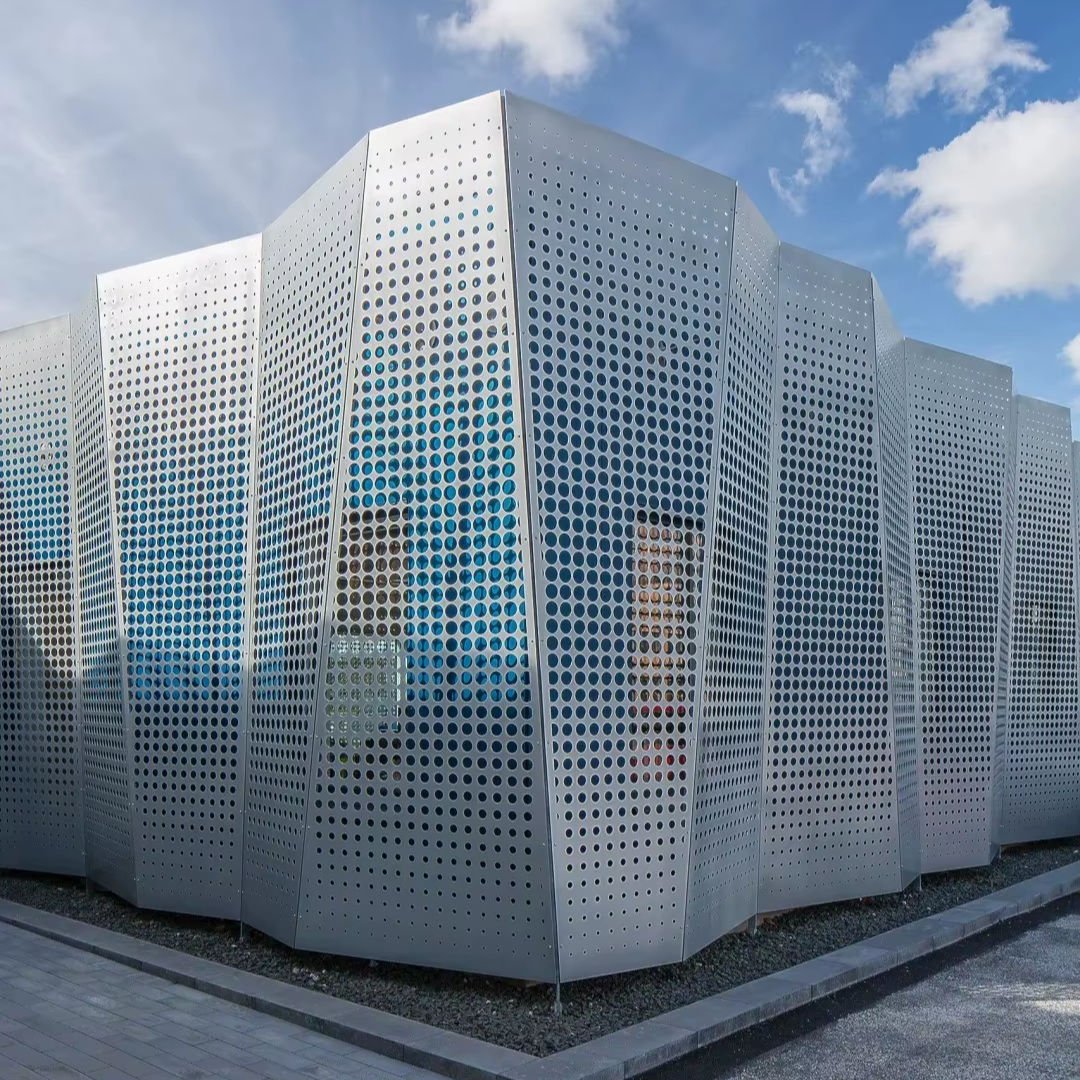

PVDF-Coated Finish A high-performance finish featuring a Polyvinylidene Fluoride (PVDF) coating that resists weathering, corrosion, and color fading. Widely used in aluminum façade systems and architectural curtain walls.

Anodized Finish A protective oxide layer formed through an electrolytic process enhances corrosion resistance and allows vibrant color options. Anodized aluminium is ideal for outdoor façades, sunshades, and curtain walls.

Why Surface Finish Matters

From visual goals to functional demands, surface finishing is a crucial element of architectural sheet metal design. Choosing the right finish influences not only the appearance but also durability, maintenance, and environmental performance.

Key Considerations:

Define Project Goals: Identify functional and aesthetic objectives, including resistance to wear, weather, and corrosion, as well as your preferred surface texture and appearance.

Understand Material Behavior: Recognize the inherent strengths of stainless steel (durability, corrosion resistance) and aluminium (lightweight, formability), and how finishes interact with these properties.

Assess Environmental Conditions: Evaluate the environmental exposure—UV rays, humidity, chemicals—to determine the required protection level your finish must deliver.

Compare Finish Options: Different finishes serve different roles. For instance, a mirror finish delivers glamor, while anodized or PVDF finishes offer advanced protection for exterior environments.

Consider Maintenance Needs: Determine how much maintenance is acceptable for your application. Mirror and polished finishes may need frequent cleaning, while satin and coated surfaces are lower maintenance.

Align with Aesthetic Vision: Ensure the finish complements the overall design language. Finishes contribute to architectural storytelling and should enhance the space’s visual identity.

Budget Wisely: Weigh the initial cost against long-term value. Some high-performance finishes might cost more upfront but offer significant savings through longevity and lower maintenance.

Explore Customization: Many finishes can be customized in terms of color, pattern, or texture, allowing for a personalized and distinctive architectural statement.

Understand Application Methods: Know the technical requirements for applying each finish. Some need specialized equipment or controlled environments to ensure uniform quality.

Seek Professional Guidance: Consult with material experts or manufacturers (like XYC Metalworks) to understand what works best for your unique project—both in terms of application feasibility and expected performance.

Test Samples: Request samples for real-world evaluation. Testing finishes on-site helps verify color, texture, reflectivity, and performance under specific conditions.

Benefits of Sheet Metal Finishes in Architecture

Sheet metal finishes enhance both the appearance and performance of stainless steel and aluminium elements in architectural projects. Key benefits include:

✔ Durability: Resists corrosion, scratches, and UV damage—ideal for both interior and exterior use.

✔ Design Flexibility: Formable and customizable to suit intricate designs, curves, and unique profiles.

✔ Aesthetic Impact: From sleek modernism to industrial minimalism, finishes elevate the visual tone of your project.

✔ Low Maintenance: Finishes are engineered to minimize upkeep, resist fading, and maintain a clean look over time.

✔ Energy Efficiency: Reflective finishes can reduce heat absorption, improving building energy performance.

✔ Sustainability: Aluminium and stainless steel are fully recyclable, supporting LEED certifications and green building standards.

✔ Fire Resistance: Non-combustible properties make these finishes suitable for applications requiring elevated fire safety.

✔ Long-Term Value: While some finishes come at a premium, their extended lifespan and reduced maintenance lead to lower lifecycle costs.

Our architectural metal sheet & panels collection is characterized by a comprehensive range of advanced innovative products for the enhancement of architectural development. Through decorative screens to functional balustrades and bespoke statues, we offer aesthetics together with durability, making the opportunities for creative design applications endless.

Finish and Pattern Options

Surface Finishes Available

Run ashet metal design that is eniched with our widerange of finishes and patterms, providing you with an excitingjourney. Fram the vivid appeal ofwateripplemetal to the advancedaccuracy of laser-cutand corugated vanants, our assortment provides a range that can enhance your proiect’s aesthetic experience from an artistit as wellas architectural perspective.

Metal wall facade cladding is excellent to provide architectural projects with structural functionalities and aesthetic elements. Facade cladding systems by TBK Metal include …

With our fabricating expertise and innovative design, we provide metal ceiling systems with outstanding performance and stunning styles, and offer overall solutions with flexibility …

With your unlimited and endless creative ideas, decorative metal screen panels can be customized with a wide variety of styles and designs. Metal screen panels provide exclusive patterns …

The architectural sculptures manufactured by TBK Metal are supposed to lift the identity of various spaces. Our work fills the scene visually, culturally, and practically, whether ...

A huge variety of sheet metal finishes and patterns reveals a universe that provides both architectural and design wonders. Whether embracing the delicate refinement of Brushed Metal or defying limitations through bonded metal, our range lets you create spaces in harmony with smartness and aesthetics.

FAQs: Sheet Metal Surface Finishes

Q1: What are the most common finishes for stainless steel and aluminium?

A: Common stainless steel finishes include brushed, mirror, satin, and vibration. Aluminium often features mill, anodized, PVDF-coated, and powder-coated finishes.

Q2: How do finishes affect corrosion resistance?

A: While stainless steel is inherently corrosion-resistant, mirror and satin finishes can enhance its performance. Anodized and PVDF-coated aluminium also offer excellent protection in harsh environments.

Q3: Can finishes be customized?

A: Yes. You can personalize finishes through color, pattern, and texture variations—ideal for creating a signature aesthetic.

Q4: What’s the difference between brushed and polished stainless steel?

A: Brushed finishes feature fine, directional lines for a matte look, while polished finishes are highly reflective and smooth like a mirror.

Q5: Are these finishes suitable for outdoor use?

A: Absolutely. Many finishes are engineered for exterior performance, particularly anodized aluminium and PVDF-coated surfaces.

Q6: How do I maintain metal finishes?

A: Regular cleaning with mild soap and water usually suffices. Avoid abrasives and harsh chemicals to preserve the integrity of the finish.

Q7: Can finishes be applied to complex shapes?

A: Yes. The flexibility of stainless steel and aluminium allows for finishing on curves, angles, and 3D forms without sacrificing quality.

Q8: What’s the difference between anodized and powder-coated aluminium?

A: Anodizing creates a metallic, corrosion-resistant layer, while powder coating forms a durable, colorful film. Both offer excellent weather protection.

Q9: Are metal finishes environmentally friendly?

A: Yes. Many are low-VOC, recyclable, and comply with green building standards. Finishes like anodizing and powder coating are considered sustainable.

Ready to Start Your Project with XYC Metalworks?

XYC Metalworks delivers sheet metal products backed by expert workmanship and a contemporary outlook, making us a leader in industrial and architectural fabrication.

Final Thoughts

Whether you seek timeless elegance, industrial texture, or ultra-modern brilliance, XYC Metalworks’ stainless steel and aluminium sheet metal finishes offer the versatility, resilience, and beauty to elevate any architectural vision. With a wide spectrum of styles and technical strengths, these finishes not only protect but also define the visual language of your space—turning materials into meaningful design.

Industry Expertise

Our highly skilled team knows how to optimally produce the metal finish and guarantees to create a finish that is in line with your aspirations.

High-Quality Materials

We employ superior quality metals for captivating and enduring metal finishes giving architectural or interior design projects longevity.

Custom Solutions

The decorative panels can be produced in the preferred or desired hue, surface texture, and weave structure that you desire for your project.

Exceptional Service

Making customers content is always our goal, and effective communication, problem solving, and timely help guarantee a smooth project process.

Sustainable Practices

Such as using environmentally friendly materials, recycling, and reducing waste, to achieve aesthetically attractive and sustainable metal finishes.

Competitive Pricing

Our patina finish services are affordable while still providing high quality and we ensure that our prices are amongst the fairest in the market today.

Start Your Next Iconic Project

Contact our engineering team today to get a custom quote for your project or to schedule a factory tour.

Contact Form

Headquarter (China)

XYC Metalworks Co., Ltd

- No.1 Dashi Industry Zone, Lishui, Nanhai, Foshan, Guangdong, China

- +86 18923114885

- +86 18923114885

- Sales@xycmetalworks.com

- www.xycmetalworks.com