XYC Metalworks

Doha Metro Project, Qatar

- Home

- Projects

- Transportation

- Doha Metro Project, Qatar

Doha Metro Project, Qatar

Project Case Study: Doha Metro, Qatar

Elevating Public Transport with Bespoke Architectural Metal Solutions

The Doha Metro stands as a testament to modern engineering and ambitious architectural vision, creating one of the most advanced public transport systems in the world. This landmark project, defined by its signature “vaulted spaces” inspired by traditional Bedouin tents, required an extraordinary level of precision, durability, and aesthetic excellence in all its components.

Our company was honored to be a key supplier, fabricating and delivering a comprehensive range of bespoke architectural metal products that define the stations’ interiors, exteriors, and the metro cars themselves. Our work met the project’s stringent demands for both luxury finishes and transportation-grade durability.

Key Metalwork Solutions Provided:

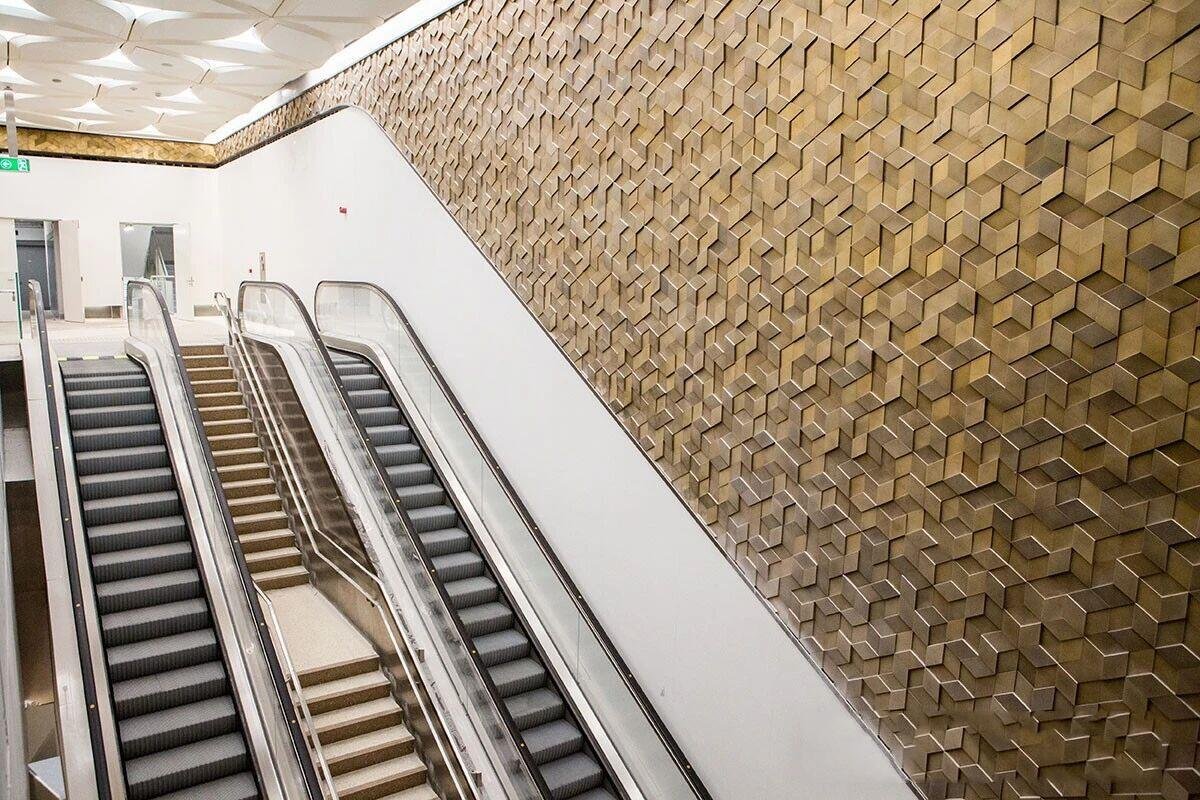

3D Geometric Wall Cladding: The project’s most iconic interior feature. We manufactured the custom 3D metal wall panels in both gold and bronze PVD finishes. These tessellated, diamond-pattern tiles cover vast expanses of the station walls, creating a dynamic play of light and shadow that enhances the “vaulted space” concept.

Architectural Ceiling & Archway Systems: We produced the intricate perforated metal ceiling panels with complex geometric patterns, contributing to the stations’ unique acoustics and modern Islamic-inspired aesthetic. This included fabricating curved metal archways and decorative ceiling trim that integrate seamlessly with the futuristic lighting.

Transportation-Grade Handrails & Balustrades: Safety and high-traffic durability were paramount. We supplied extensive stainless steel handrail systems for all escalators and station stairways. This also included bespoke profiled metal handrails in a bronze finish, which cap the glass balustrade systems throughout the concourses.

Metro Car Interior Components: Our work extended directly into the metro cars. We manufactured the high-polish stainless steel grab poles, vertical passenger handrails, and other durable metal fixtures essential for passenger safety and comfort.

Specialized Cladding & Finishing: We provided a variety of specialized cladding solutions, including patterned stainless steel elevator cladding and robust column covers (both round and curved profiles). Our scope also included functional items like stainless steel floor grates, tactile paving strips, and skirting boards, ensuring a cohesive and high-quality finish across the entire project.

From the grand concourse walls to the handrails inside the train cars, this project showcases our capability to execute complex, large-scale architectural metal contracts for the world’s most demanding infrastructure projects.