XYC Metalworks

FAQS

- Home

- FAQS

Frequently Asked Questions (FAQs)

Get Answers to Your Common Questions

Get Answers to Your Common Questions

The Frequently Asked Questions (FAQ) section of XYC Metalworks is now open for your review. Here below, we answer some of our most asked questions about our services, products, and company conditions. Our support team remains available for response when you need additional help.

Q1: What does XYC METALWORKS specialize in?

A: XYC METALWORKS specializes in custom architectural and decorative metal fabrication. We produce high-quality stainless steel, aluminum, brass, bronze, and other metal products for commercial buildings, hospitality projects, luxury residences, public spaces, and industrial applications.

Q2: Which industries do you serve?

A: We serve architects, contractors, developers, designers, and manufacturers across hospitality, transportation, commercial real estate, retail, landscape architecture, and public infrastructure.

Q1: What types of metal products do you offer?

A: Our product range includes:

Stainless steel sheet and profiles

Decorative metal panels (laser-cut, perforated, embossed, expanded, woven)

Balustrades, railings, handrails

Metal cladding and façade panels

Architectural screens, partitions, and feature walls

Customized structural and decorative metal components

Q2: Do you offer custom design and fabrication?

A: Yes. We provide full customization including bespoke patterns, surface finishes, complex shapes, structural components, and project-specific engineering solutions. You may submit drawings, sketches, or even design concepts—we’ll turn them into manufacturable products.

Q3: What materials do you commonly work with?

A: Stainless steel 304/316/316L, aluminum alloys (5000/6000 series), brass, bronze, copper, galvanized steel, and specialty metals depending on project requirements.

Q4: What material grades do you commonly use for stainless steel fabrication?

A: We primarily use 304, 304L, 316, and 316L stainless steel for architectural applications. For coastal or highly corrosive environments, 316L is recommended due to its low carbon content and enhanced corrosion resistance. Material certificates (MTC 3.1) can be provided on request.

Q5: What aluminum grades are available for façade and cladding projects?

A: We work with 5052, 5083, 5754, 6061, and 6063 depending on structural and forming requirements.

5-series (Mg-based): excellent for bending, rolling, and marine environments

6-series (Mg-Si-based): suitable for structural frames, CNC machining, and extrusion

Q6: What thickness range do you support?

A:

Stainless steel sheets: 0.5–20 mm

Aluminum sheets/panels: 1.5–8 mm

Perforated/laser-cut panels: 1–6 mm

Custom structural components: based on project design

Q7: What surface finishes can you provide for stainless steel?

A:

No.4 satin / Hairline

No.8 mirror polish

Bead-blast matte finish

Vibration finish

PVD Titanium coating (gold, black, bronze, champagne, etc.)

Etching / embossing / water ripple texture

Q8: What coatings are recommended for aluminum on façade applications?

A:

PVDF coating : excellent UV and corrosion resistance

Powder coating: durable and cost-effective for interior & light exterior use

Anodizing: architectural-grade AA15–AA25 for anodized colors or metallic finish

Q1: What is your minimum order quantity (MOQ)?

A: MOQ varies by product type and complexity. Standard items require lower MOQ, while bespoke architectural components may require higher quantities. Small samples or mock-ups can be produced on request.

Q2: How can I request a quotation?

A: Send us your drawings (PDF/CAD), material requirements, finish preference, quantities, and any technical details. Our engineering and sales team will review the information and provide a detailed quotation within 24 hours.

Q3: Do you provide samples or mock-ups?

A: Yes. Sample pieces or full-size mock-ups are available for surface finish confirmation, structural evaluation, and project approvals. Sample cost varies depending on complexity and materials.

Q4: Can you assist with shop drawings?

A: Absolutely. We can prepare shop drawings, fabrication drawings, installation diagrams, and technical documents for approval before production begins.

Q5: What fabrication processes do you support?

A: Our capabilities include:

CNC laser cutting, fiber laser cutting

CNC bending, forming, rolling (up to large-radius curves)

TIG/MIG welding, robotic welding

Metal stamping, punching, embossing

Surface finishing: brushing, mirror polishing, bead blasting, powder coating, anodizing, PVD coating

Assembly of complex architectural modules

Q6: What are your tolerances for architectural metalwork?

A: Standard tolerances follow ISO 2768-m or GB/T 1804-m unless otherwise specified.

Typical values:

Cutting tolerance: ±0.2–0.5 mm

Bending tolerance: ±1.0 mm

Panel flatness: ≤ 2 mm / meter (depending on material and thickness)

Q1: Do you support international shipping?

A: Yes. We export worldwide and can coordinate sea freight, air freight, or express delivery. We handle packaging, documentation, and export procedures to ensure smooth delivery.

Q2: What is your general production lead time?

A: Lead time depends on order volume and complexity:

Standard items: 1–3 weeks

Custom metalwork: 3–8 weeks

Large façade or architectural projects: lead time varies and will be confirmed during quotation

Q1: Do you provide installation services?

A: We provide installation assistance, technical guidance, and on-site support for large projects. We also work with qualified installation partners when full installation services are required.

Q2: How do I maintain metal products?

A: Maintenance depends on the material and finish:

Stainless steel: Clean routinely with mild detergent; avoid abrasive cleaners.

Aluminum: Rinse with water; protect coated or anodized surfaces from scratching.

Copper & brass: Natural patina is normal; polishing is optional if a bright finish is desired.

We can provide a maintenance guide for each project.

Q3: Do you provide structural calculations for cladding and railing systems?

A: Yes. We can support wind-load analysis, panel thickness recommendations, bracket spacing, and fixing system design based on local building codes and engineering requirements.

Q4: Do you fabricate sub-frame and fixing systems?

A: Yes, we provide full systems including:

Aluminum / stainless steel subframes

Adjustable brackets

Anchor plates

Rivet, bolt, and concealed fixing systems

Our systems are compatible with concrete, block walls, structural steel, and composite substrates.

Q5: Can your panels accommodate integration with MEP, fire systems, or lighting?

A: Yes. We can include openings, stiffeners, access panels, and support brackets for lighting, speakers, sprinklers, ventilation grilles, and fire-rated assemblies.

Q1: How do you ensure product quality?

A: We follow a strict quality control system including material inspection, precision fabrication, welding checks, surface finishing control, and final QC before packing. Testing reports can be provided upon request.

Q2: What if the products do not match my expectations?

A: If any product does not conform to approved drawings or samples, we will provide replacement, rework, or other solutions. Customer satisfaction is our priority.

Q3: How can I contact XYC METALWORKS for support?

A: You can reach us via email, phone, WhatsApp, or our website contact form. Our team responds within 24 hours for all technical and commercial inquiries.

Architectural Metal Works

Serve projects with innovative design and premium quality

As a leading global stainless steel and metal manufacturer for architectural applications, TBK Metal provides luxury decorative parts that enhance architectural aesthetics. Everything ranging from basic to complex is made with the concept of a piece for everyone to look elegant.

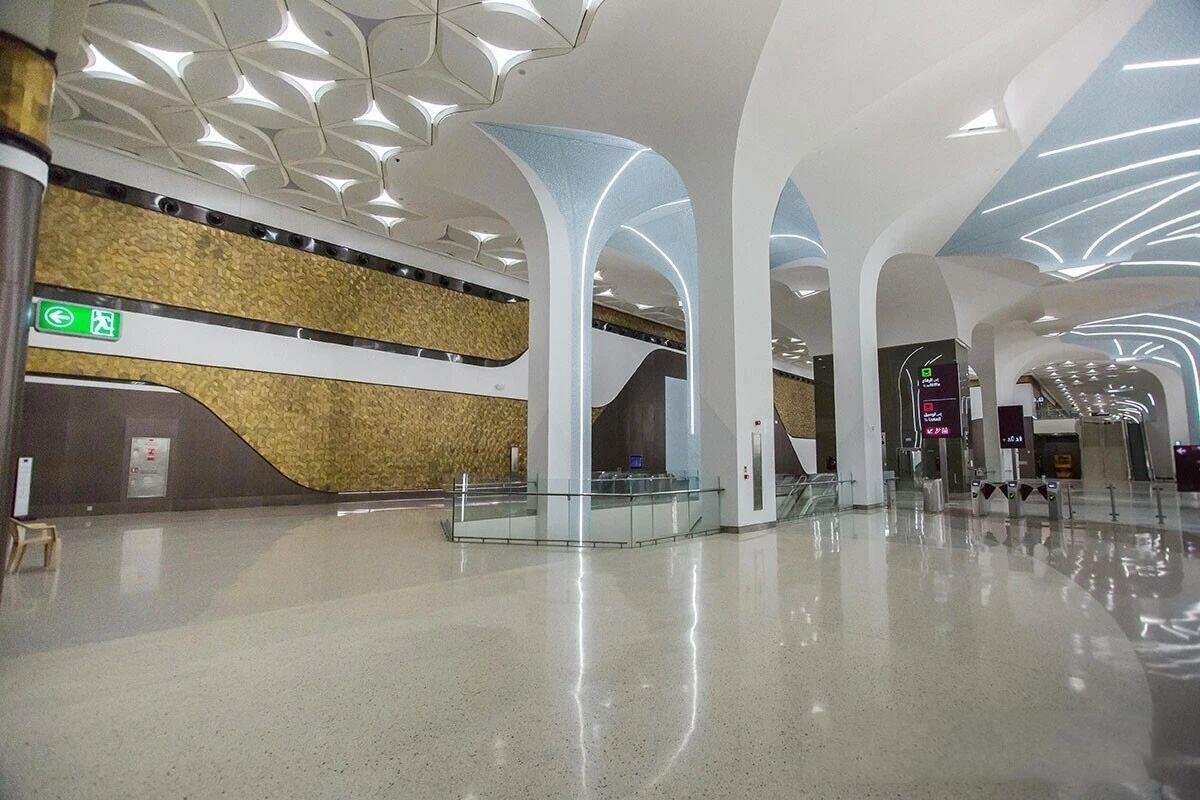

Superior Visual Impact Our wall systems transform interior spaces from standard to exceptional. Whether applied as a dramatic Modern Metal Feature Wall or a complete lobby finish, the luster, texture, and color of metal dramatically enhance a space's sophistication. This is the essence of Luxury Interior Wall Cladding.

We offer advanced, bespoke metal ceiling systems engineered to enhance both form and function within the world's most demanding architectural environments. Our solutions are not just products; they are engineered partnerships for performance, safety, acoustics, and design harmony, specified for premier commercial buildings...

Custom Metal Sculptures and Architectural Artworks are defining elements that create identity, inspire awe, and establish a focal point in public and private spaces. At XYC Metalworks...

Fabricated from high-grade stainless steel, these column enclosures are engineered to withstand corrosion, impact, and weather extremes, delivering enduring performance in both indoor and outdoor environments5 ...

we offers a premium range of stainless steel components designed to enhance both the functionality and aesthetics of elevator interiors and escalator systems. Upgrade your space with top-grade …

Architectural staircases and stainless steel railing systems are far more than structural barriers or vertical pathways—they are central design statements that unite safety with sophistication.

Architectural stainless steel interior doors and custom pull handles are far more than mere functional elements; they are transformative design statements that define a space's character. From a grand...

In any luxury hotel, corporate lobby, or high-end retail space, the custom metalwork defines the brand's physical identity. These are the critical touchpoints—from the monolithic reception desk a guest first ...