XYC Metalworks

Table of Contents

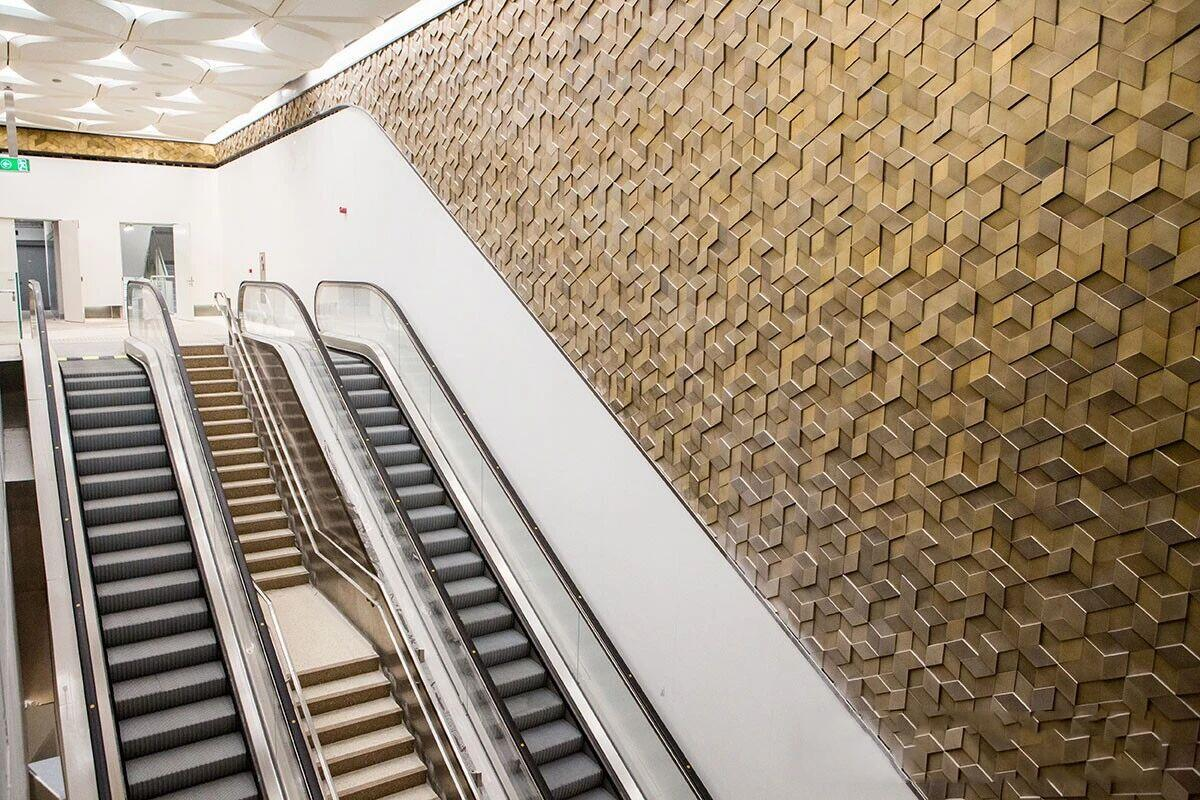

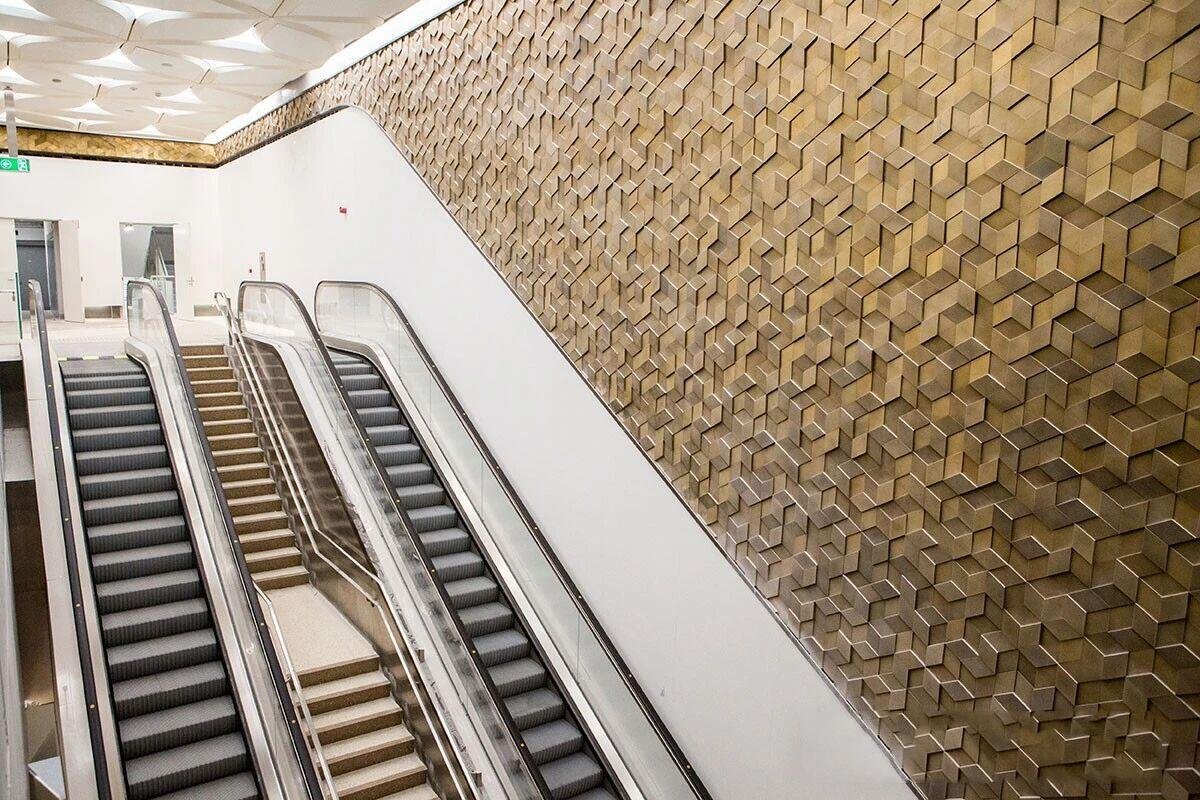

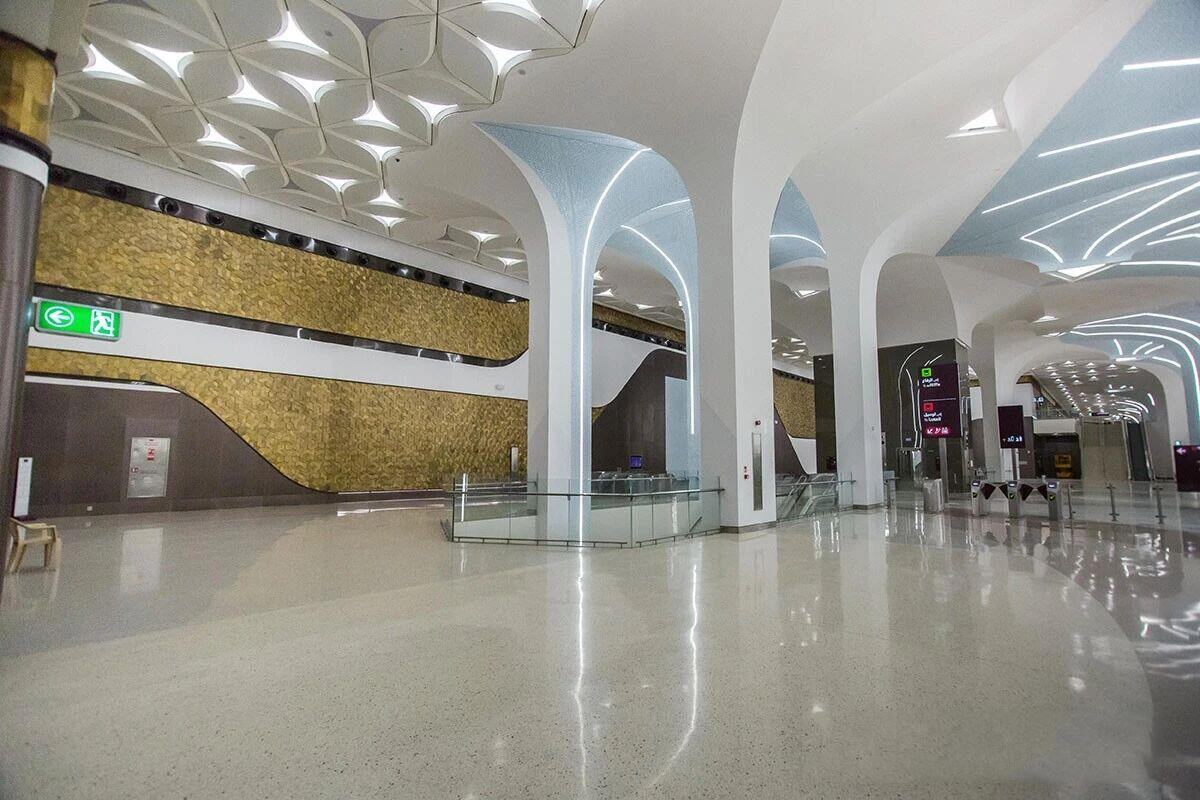

The Doha Metro is more than a transportation system; it’s a statement of national vision, defined by its vaulted, palatial interiors. As premier fabrication partners for this landmark project, XYC Metalworks was tasked with manufacturing and supplying over 50,000 individual 3D geometric wall panels. This wasn’t a challenge of complexity—it was a challenge of scale meeting perfection. How do you ensure that panel #49,872 has the identical precision and finish as panel #1? This is the story of quality control in mass production.

The Challenge: From a Single Panel to an Acre of Cladding

For architects and designers, the greatest vision can be undermined by the smallest inconsistency. The core challenge for the Doha Metro’s 3D panels was maintaining absolute uniformity across a staggering quantity.

Geometric Precision: Each panel features a complex, multi-faceted 3D geometry. Any deviation in angle or depth would be instantly visible when panels were tessellated.

Finish Consistency: The PVD gold finish needed to be perfectly consistent in color, sheen, and texture across thousands of square meters, under varying lighting conditions.

Logistical Scale: This volume required a fabrication plan that was part-artisan, part-assembly line.

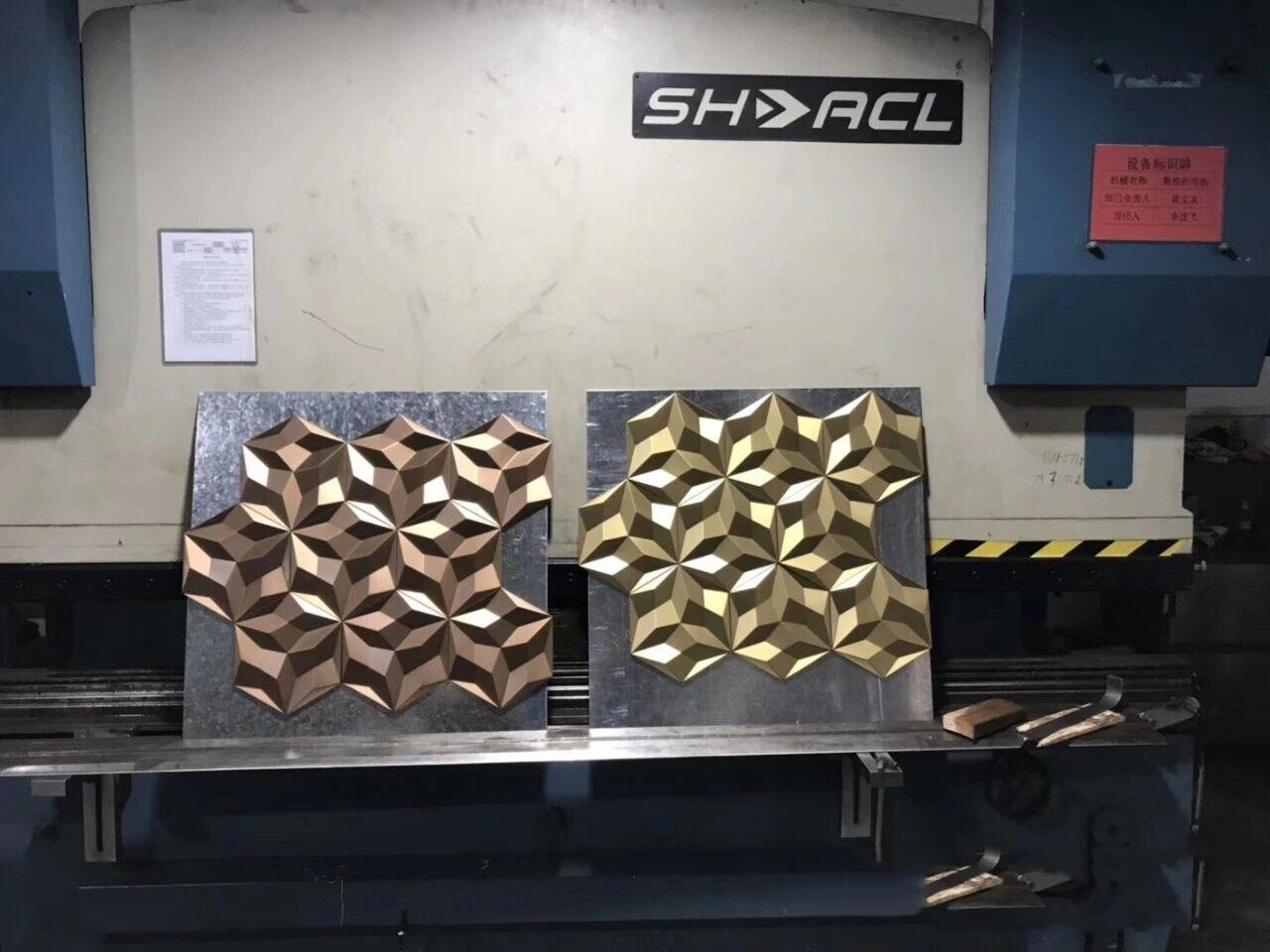

Perfecting the “0”: Prototyping and QC Benchmarks

Before a single panel was mass-produced, we perfected the “zero.” Our process began with rigorous prototyping and 1:1 mock-ups.

We fabricated initial reference panels, testing everything from the aluminum substrate to the folding precision and the PVD coating adhesion. These “benchmark panels” became the non-negotiable standard against which every subsequent piece would be measured. This phase allowed us to refine our shop drawings and develop custom jigs and tooling to guarantee precision, moving from a craftsman’s prototype to a fabrication-ready plan.

Scaling to “50,000+”: The Art of Industrialized Precision

This is where XYC’s core strength in precision engineering merged with industrial-scale logistics.

Dedicated Production: We established dedicated production lines with stations for laser cutting, CNC bending, and finishing.

Relentless QC: A “pass/fail” QC check was implemented at every stage. Our technicians (and the client’s) inspected panels not just for defects, but for microscopic geometric and color deviations against the approved benchmark.

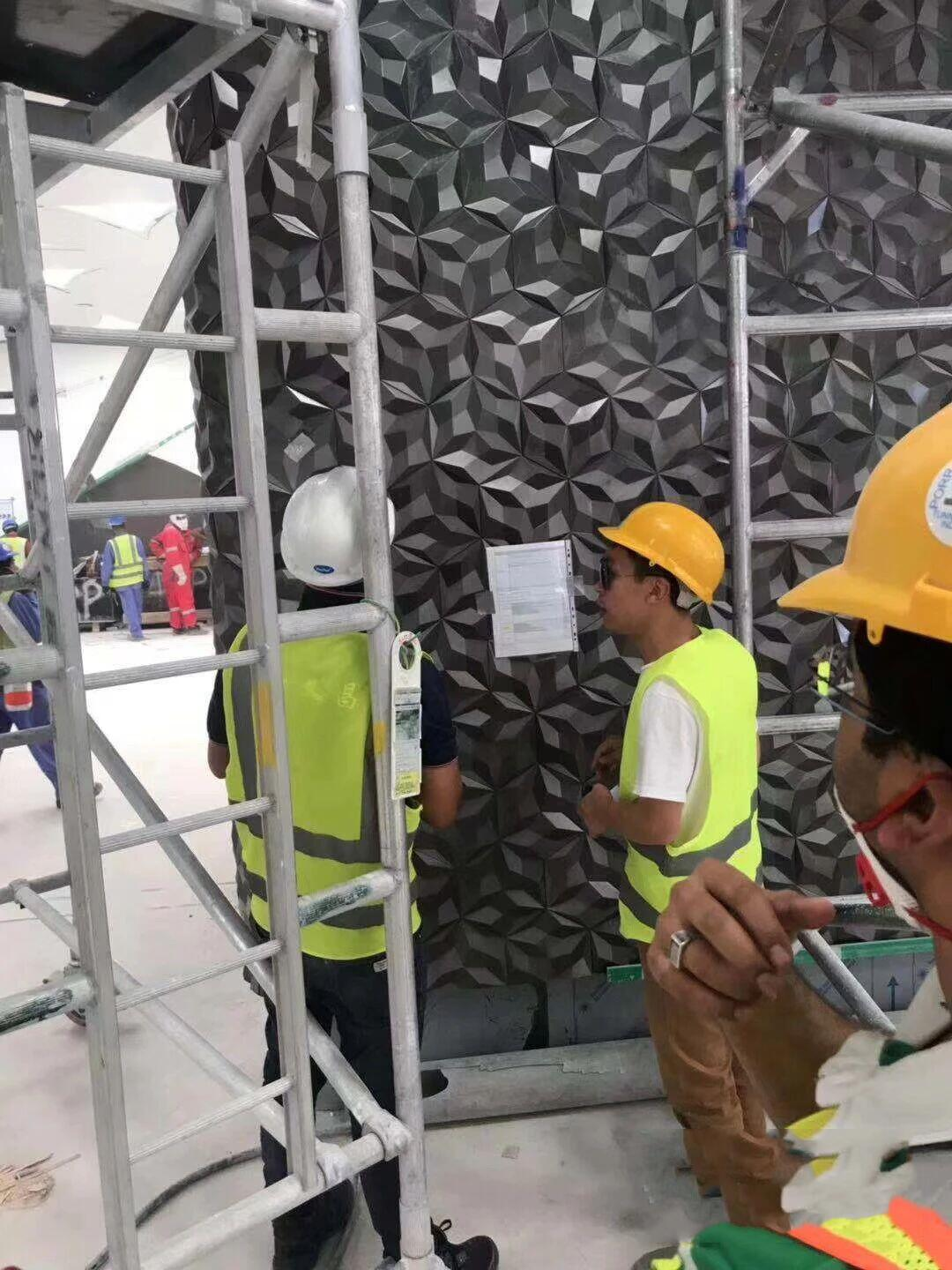

Intelligent Labeling: Each panel was individually labeled with its exact location (Station, Wall, Row, Position) to streamline the complex on-site installation.

This meticulous process ensured that the panels arriving in Doha were not just components, but a pre-verified, puzzle-piece system ready for assembly.

From Factory to Landmark: A Seamless Installation

The final “test” of our quality control was the installation. Thanks to the precision-engineered panels and the detailed on-site shop drawings, the installation teams could efficiently mount the panels, creating the vast, seamless, and shimmering surfaces that define the project.

The result is a public space that feels as luxurious and meticulously crafted as a five-star hotel lobby, proving that high-design and high-volume can coexist. For architects, this project serves as a case study: your most ambitious, large-scale designs are not only possible, but they can be executed with the precision of a single, perfect piece—50,000 times over.

Search

Recent Comments

Recent Posts

- An Architect’s Guide to PVD Coating: Why It’s the Superior Finish for High-Traffic Luxury Spaces November 21, 2025

- From 0 to 50,000+: The Quality Control & Mass Production of 3D Gold Panels for the Doha Metro November 21, 2025

- From Mock-up to Masterpiece: A Case Study in Precision Metalwork for the NBK HQ November 21, 2025

- More Than a Cover: How Column Cladding is Redefining Commercial Lobbies November 21, 2025

- Why We Build it Twice: The Critical Role of the 1:1 Mock-up in Our Process November 21, 2025