XYC Metalworks

Interior

- Home

- Product Reviews

- Interior

Welcome to XYC Metalworks’ line of custom interior metal fabrication solutions.

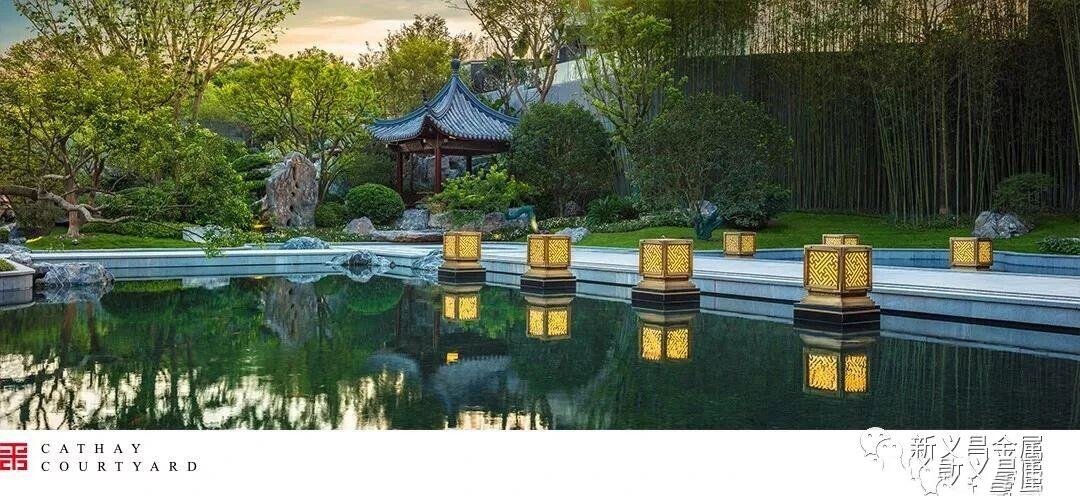

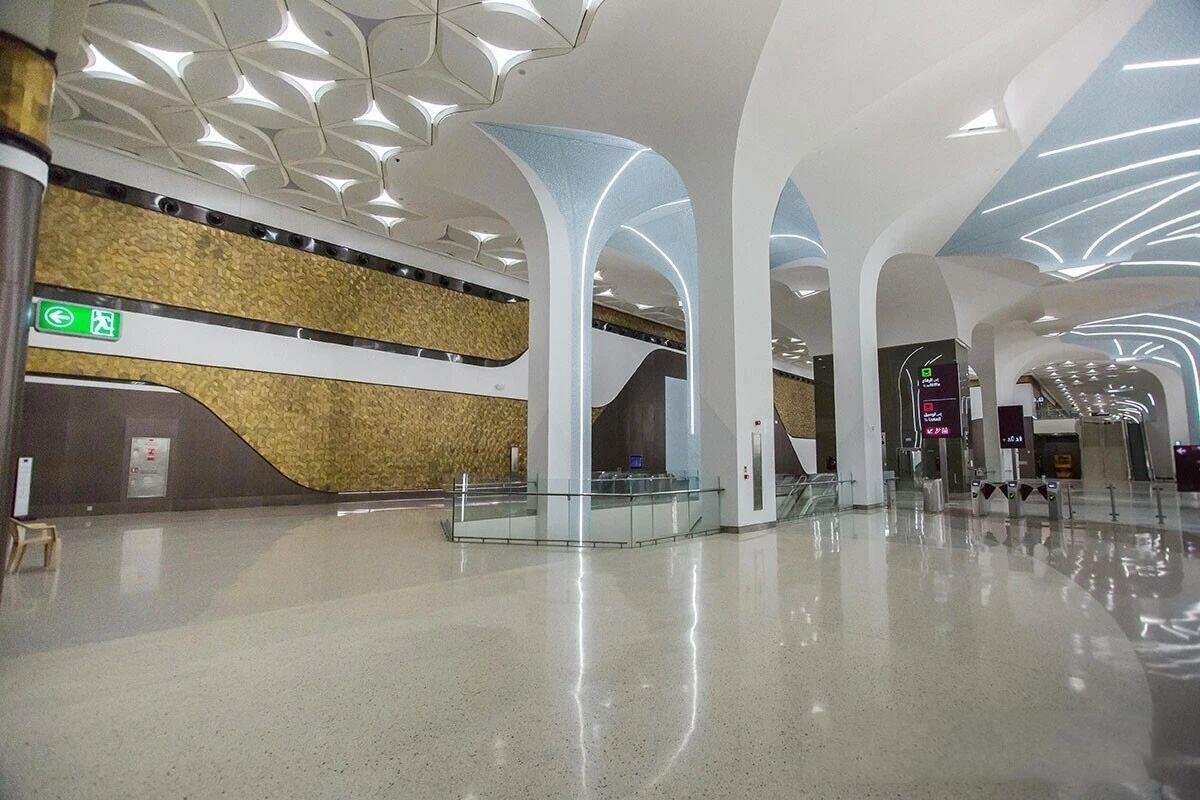

As a leading international manufacturer in architectural metal fabrication , we specialize in transforming high-quality architectural metals—tainless steel, aluminum, and brass, bronze & copper—into sophisticated, custom metal solutions. Our products and engineering services are widely applied in iconic interior projects globally, including luxury hospitality, high-end commercial, retail & office spaces, and high-end residential developments.

We are committed to providing comprehensive, turnkey solutions. Through superior design, precision fabrication, and patented technology, we transform the visions of architects and designers into perfect metal art pieces.

Core Product Categories

We offer a full spectrum of custom interior metal products. Below is a detailed look at our primary product range:

Pattern Options

A Wide Range of Pattern Options

Architectural metal panels having a variety of patterns will not only impress the opulent looks but also can work functionally for architectural projects. Let us take a closer glance at all the designs that a designer possesses, having those open for architects and designers enables them to integrate functional features with the help of creative expression.

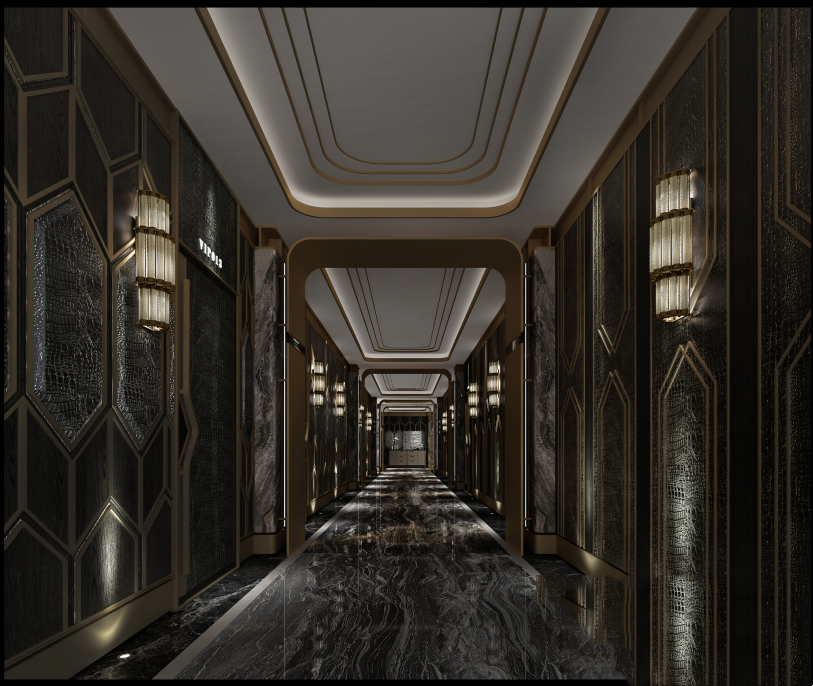

Superior Visual Impact Our wall systems transform interior spaces from standard to exceptional. Whether applied as a dramatic Modern Metal Feature Wall or a complete lobby finish, the luster, texture, and color of metal dramatically enhance a space's sophistication. This is the essence of Luxury Interior Wall Cladding.

We offer advanced, bespoke metal ceiling systems engineered to enhance both form and function within the world's most demanding architectural environments. Our solutions are not just products; they are engineered partnerships for performance, safety, acoustics, and design harmony, specified for premier commercial buildings...

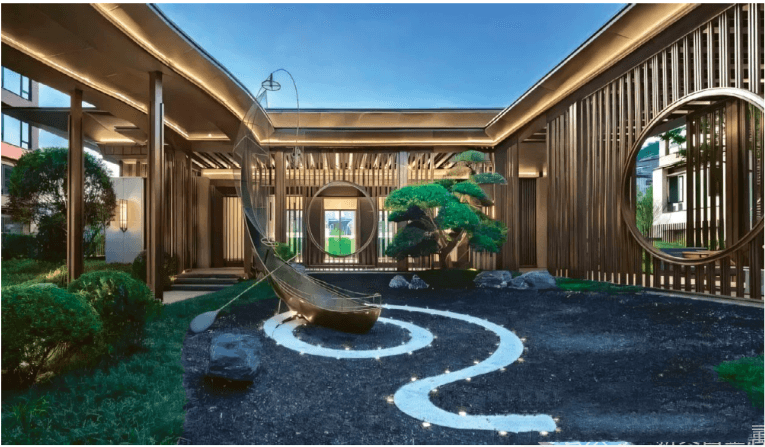

Custom Metal Sculptures and Architectural Artworks are defining elements that create identity, inspire awe, and establish a focal point in public and private spaces. At XYC Metalworks...

Fabricated from high-grade stainless steel, these column enclosures are engineered to withstand corrosion, impact, and weather extremes, delivering enduring performance in both indoor and outdoor environments5 ...

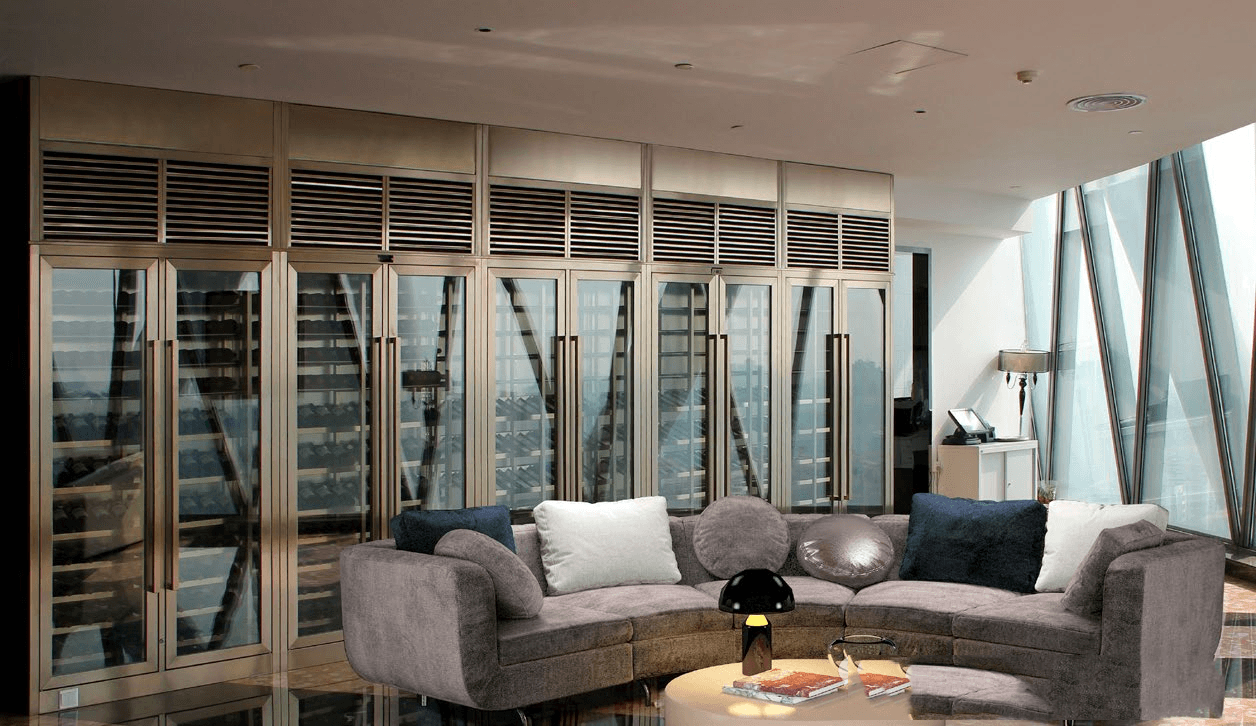

we offers a premium range of stainless steel components designed to enhance both the functionality and aesthetics of elevator interiors and escalator systems. Upgrade your space with top-grade …

Architectural staircases and stainless steel railing systems are far more than structural barriers or vertical pathways—they are central design statements that unite safety with sophistication.

Architectural stainless steel interior doors and custom pull handles are far more than mere functional elements; they are transformative design statements that define a space's character. From a grand...

In any luxury hotel, corporate lobby, or high-end retail space, the custom metalwork defines the brand's physical identity. These are the critical touchpoints—from the monolithic reception desk a guest first ...

Architects and designers can achieve multiple design objectives such as harmony in facades beauty and performance in addition to the existing trend in customization utilizing flexibility in patterns of metals. This provides different projects with the opportunity to express their personalities and styles through our distinctive pattern applications.

Manufacturing Edge & Materials

Core Materials

Stinless Steel:Exceptional corrosion resistance and strength, ideal for high-demand and luxury environments.

Aluminum:Lightweight yet strong, suitable for large-scale ceilings and complex custom shapes.

Brass, Bronze, & Copper : Offers a luxurious, warm aesthetic that is ideal for high-end decorative elements, and develops a beautiful, stable patina over time.

Patented Process Guarantee

The quality of our interior products is underpinned by pioneering innovation, which holds over 20 patents.

- Seamless Welding:A proprietary process to create monolithic metal structures with no visible seams, achieving a flawless aesthetic as if carved from a single block.

- Precision Forming:Patented V-grooving and bending for perfectly sharp, zero-radius corners—a hallmark of luxury aesthetics.

- Advanced Surface Finishes:Patented nano anti-fingerprint and self-cleaning coatings that ensure installations remain pristine and low-maintenance.

Surface Finishes

The finishing process defines the final aesthetic and tactile quality of the metal. We offer a comprehensive range of industry-leading finishes to meet any design requirement, all maintained with our patented anti-fingerprint technology.

The utilization of our brushed metal sheets will elevate the quality and sophistication of your project. Refined, the finish harmoniously fits in with any design style. Select brushing, satin, or vibration finishes that would reflect a sense of class.

Transform surfaces using sandblasted metal sheets creating a visually appealing and tactile effect. These sheets are suitable for accent, gracing both interior and exterior areas with one–of–a–kind characters that transfigure into something unique.

To bring decadence back into your places, use mirror-polished metal sheets. Reflective surface increases luxury, so they are ideal for accent pieces as well as high-end applications that epitomize timeless and classy charm.

A perfect balance between classiness and remaining understated is our satin-brushed metal sheets. Smooth and high quality, lends a touch of elegance to architectural and design elements in its application in a wide range.

Bring vibrant energy into your projects because we have metal sheets that are brushed to regular density for optimal performance. The textured effect gives a visually vibrant appearance ensuring they are perfect for businesses desiring an energetic and modern look.

Our etched metal sheets allow the personalization of surfaces through unique designs and diverse patterns. Perfect for branding, way-finding, and creative purposes these sheets offer a bespoke solution to reinforce your artistic integrity.

Increase durability and weather performance without much work using our PVDF-coated metal sheets. Designed specifically to stand up against the elements in outdoor applications, they make a superb selection where architectural features must withstand extended exposure.

To prolong life and liveliness, use anodized metal sheets for upgrade. The product anodized with precision developed a protective layer giving durability and at the same time offering to pick from innovative colors for their architectural uses as well as decorative purposes.

A high-tech coating process that bonds vibrant color and superior durability to metal surfaces. PVD finishes offer excellent resistance to wear and corrosion, maintaining a flawless, premium aesthetic for the most demanding applications.

Patterns & Textures

Beyond simple surface finishes, we offer complex patterning to give metal surfaces a three-dimensional effect and unique character.

The corrugated metal sheets provide a classic taste to your space, yet they synchronously provide intense strength together with visual appeal. They are ideal for roofing and cladding applications, both indoors and outdoors; they demonstrate the timelessness of modernity.

Our perforated metal enables you to achieve a perfect balance between functionality and aesthetics, applying them widely for screening as well as shading purposes. Customize the perforation pattern to suit certain project demands, styling in harmony with utility.

We manufacture embossed metal sheets that are meant to enrich texture and depth, thus creating a palette of tactile richness for many design projects. Discover a wealth of patterns that help you achieve an exclusive hand-crafted design peculiar to your vision.

Learn about the flexibility of our enlarged metal sheets, with unmatched construction durability and transparency. Useful for fencing, grating, and many other architectural applications these sheets offer a rigid as well as lightweight alternative solution.

Our laser-cut metal sheets open up endless design options for unleashing your creativity. Whether elaborate patterns or custom shapes, these sheets allow projects to achieve highly complex details and accurate finished craftsmanship.

We offer water ripple metal sheets, and your spaces will be immersed in beautiful visual movements. Designed specifically for use in architectural and design settings, these sheets enable a unique fluidity to surfaces that become expressive canvases of art.

Your Partner in Metal Engineering

We simplify the realization of complex metal visions through a structured, collaborative process:- Inquiry & Concept Review:We begin with a detailed review of your architectural drawings and design specifications.

- Design Consultation & Material Selection:Our engineering team provides expert advice on material suitability, finish durability, and structural feasibility, focusing on value engineering.

- Detailed Engineering & Shop Drawings:We produce comprehensive 3D models and precise shop drawings for your final approval, integrating our patented connection and installation systems.

- Precision Fabrication & QA:Utilizing our ISO-certified facilities and advanced CNC equipment, fabrication adheres to strict quality control, including multiple checkpoints and dry-fit assembly.

- Secure Logistics & Installation Support:Products are professionally packaged and shipped worldwide, with optional on-site technical support provided by our expert installation team to ensure perfect assembly.

Frequently Asked Questions (FAQ)

| Question | Answer |

| Q1: Can you match the finish to an existing sample? | Yes. We specialize in custom finish development and sample matching to ensure seamless consistency with your project’s existing material palette. |

| Q2: What is the typical lead time for a custom project? | Lead times vary based on complexity and volume. Generally, after shop drawing approval, fabrication takes 4–8 weeks, with additional time for specialized finishes like PVD coating. |

| Q3: How are the products installed? | We use proprietary mounting systems (often concealed clips or anchors) and our patented joining techniques to ensure a seamless look and rapid on-site installation, reducing labor time and cost. |

| Q4: Is specialized maintenance required for mirrored finishes? | Our surfaces, especially those with anti-fingerprint coating, only require simple cleaning with mild soap and a soft cloth to maintain their shine and integrity. |

| Q5: What are your customization limits (size, shape, complexity)? | We specialize in transforming complex visions into reality. Our advanced in-house machinery (including CNC bending and laser cutting) allows us to produce virtually any geometric or organic shape, including large-scale monolithic panels and intricate bespoke structures. |

| Q6: How do you ensure the chosen material and finish are suitable for the environment (e.g., humid areas)? | Our engineering team provides detailed material consultation. For high-humidity or high-traffic areas, we recommend specific alloys like 316L stainless steel and finishes with our patented anti-corrosion or nano anti-fingerprint coatings to guarantee longevity. |

| Q7: Can you handle the logistical planning for international projects? | Yes. We have proven experience in global project delivery1. Our services include professional export crating, international logistics planning, and providing necessary structural guidance for on-site assembly worldwide. |

| Q8: Can your interior products be integrated with lighting or media systems? | Absolutely. We frequently integrate features like internal LED lighting systems for wall cladding and ceiling panels, or engineer structural support behind display furniture to allow seamless integration of screens and media equipment. |

Related Projects

Explore our portfolio of successful interior metal projects, from intricate elevator lobbies in luxury hotels to expansive wall cladding systems in commercial headquarters.