XYC Metalworks

- Lorem donec massaRated 3 out of 5

- Velit aliquet sagittisRated 3 out of 5

- Magna etiam tempor orciRated 3 out of 5

- Tristique et egestas quis ipsumRated 3 out of 5

- Cum sociis natoqueRated 3 out of 5

- Pellentesque elit eget gravidaRated 3 out of 5

Quick Summary

Rhoncus aenean vel elit scelerisque mauris pellentesque pulvinar pellentesque habitant. Ridiculus mus mauris vitae ultricies leo. Ut ornare lectus sit amet. Eu augue ut lectus arcu. Egestas quis ipsum suspendisse ultrices.

Gravida rutrum quisque non tellus orci ac. Egestas dui id ornare arcu odio ut sem nulla. Sed elementum tempus egestas sed sed risus pretium. Lectus sit amet est placerat. Consequat semper viverra nam libero justo laoreet sit amet cursus.

Specs

- Pellentesque: Gravilmusa

- Cum sociis: Natoque

- Tristiquex: Egestas quis ipsum

- Velit aliquet: Sagittis

Pros

- Phasellus vestibulum lorem

- Ridiculus mus mauris vitae

Cons

- Gravida rutrum quisque

- Egestas dui id ornare arcu

Stainless Steel

- Home

- Product Reviews

- Stainless Steel

XYC Metalworks: Stainless Steel Materials for Custom-Engineered Solutions

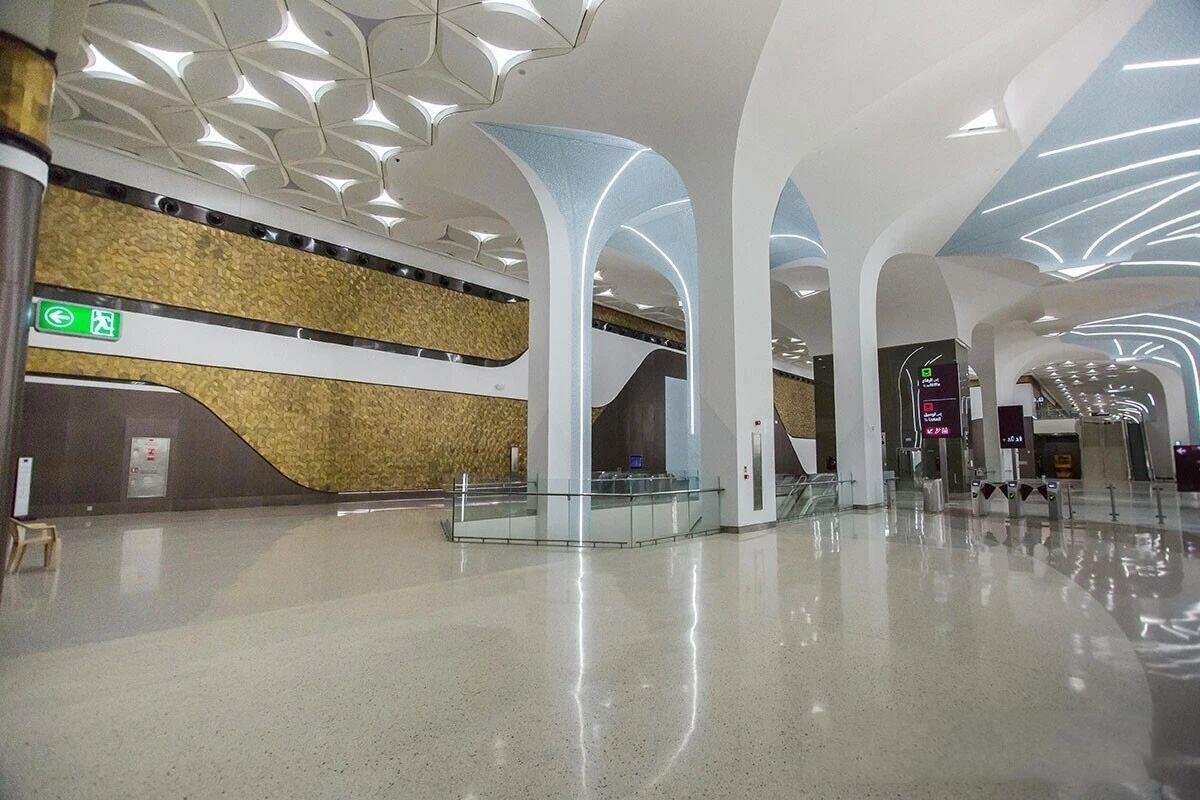

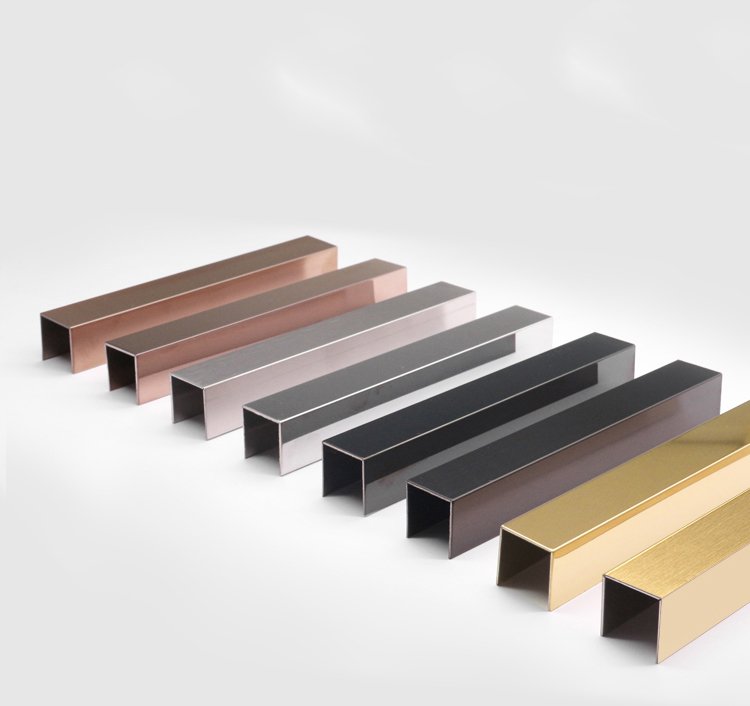

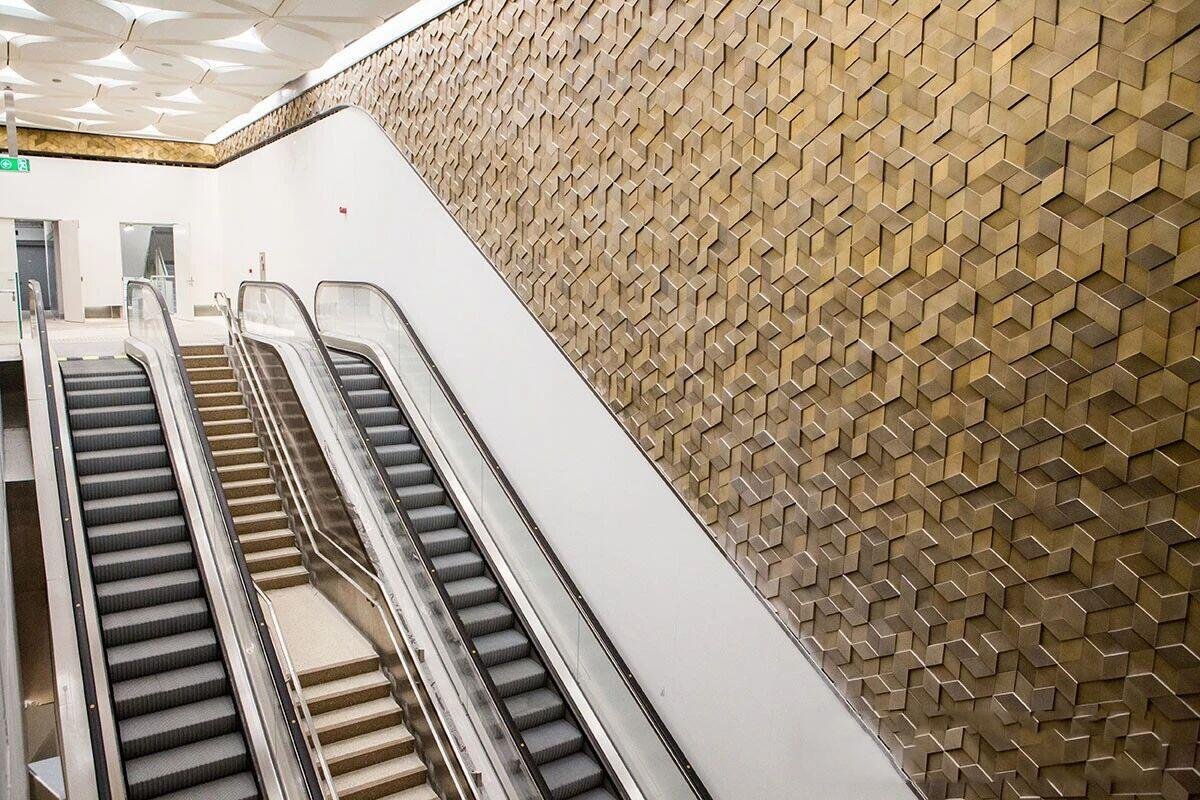

As a premier provider of 304 & 316 Stainless Steel Fabrication, XYC Metalworks delivers bespoke, custom-engineered solutions for high-end architectural and engineering projects. This comprehensive Stainless Steel Guide highlights our expertise in processing 304 stainless steel and 316 stainless steel into high-quality custom stainless steel sheets & plates and architectural stainless steel tubes. We offer a vast array of stainless steel finishes, including brushed stainless steel, mirror finish steel, sandblasted, and etched textures, ensuring that every stainless steel sheet, plate, and tube meets your exact aesthetic and functional requirements . Whether you need engineering grade steel for structural reliability or decorative profiles for luxury interiors, our precision cutting, bending, and welding services provide the perfect finishing touch for any global project.

While this information is provided for your reference and selection, our core service is to partner with you. Our team will analyze the specific details and requirements of your project to recommend and fabricate the most suitable stainless steel products, ensuring optimal performance, durability, and aesthetics for your application.

We use the highest quality 304 and 316 stainless steel products, including stainless steel sheets (coils, flat sheets), plates, and tubes. Renowned for their exceptional durability, corrosion resistance, and versatility, our products are the ideal choice for architectural, decorative, industrial, and manufacturing applications.

- Brochure Download

Stainless Steel Sheet & Plate

The stainless steel sheets and plates supplied by XYC Metalworks offer an outstanding service life and superior resistance to corrosion, capable of withstanding rain, acids, salts, and other harsh environmental factors. Their high-strength properties ensure product reliability while saving on material costs and delivering lasting performance.

Common Grades & Properties

We specialize in the two most widely used stainless steel grades: 304 and 316.

Grade 304 Stainless Steel

Composition: 18% Chromium, 8% Nickel.

Properties: Excellent corrosion resistance in a wide variety of environments. Good formability and weldability, making it easy to fabricate.

Applications: Food processing equipment, kitchen appliances, sinks, architectural trim, automotive parts.

Grade 316 Stainless Steel

Composition: 16-18% Chromium, 10-14% Nickel, 2-3% Molybdenum.

Properties: The addition of molybdenum provides superior corrosion resistance, especially against pitting and crevice corrosion in chloride environments (like marine applications).

Applications: Chemical processing equipment, pharmaceutical and medical devices, marine hardware, coastal architecture.

Stainless steel Sheet & Plate Specifications

Stainless steel sheets and plates’ Techniques/ Finishes / Grades

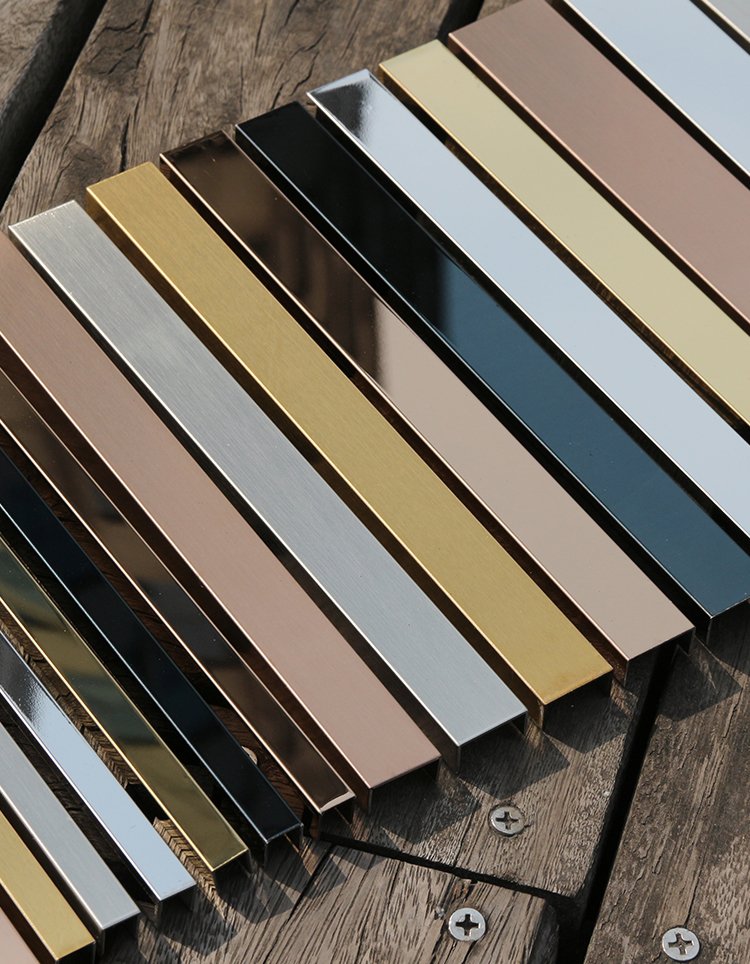

Wide Range of Surface Finishes

We offer a variety of surface treatments to meet your aesthetic and functional needs:

Brushed / Hairline (HL): A smooth, continuous-grain finish ideal for decorative and architectural applications.

Mirror (8K): A highly polished, reflective surface with a strong decorative effect.

Sandblasted: A uniform, rough matte appearance created by abrasive blasting, offering a unique texture.

Satin: A smooth, low-gloss finish that resists fingerprints, balancing beauty with practicality.

Vibration: A non-directional, textured finish that adds special visual interest to architectural and artistic projects.

Etched: Custom patterns or designs are created on the surface through chemical or laser etching.

Stainless Steel Sheet vs. Plate

Stainless Steel Sheet: Typically refers to material less than 6mm thick. It is lighter and suitable for applications where weight is a concern, such as architectural cladding, roofing, railings, and decorative elements.

Stainless Steel Plate: Refers to material 6mm or thicker. It offers greater strength and durability, making it suitable for heavy-duty structural applications like bridges, storage tanks, and industrial manufacturing.

Techniques/Finishes /Grade | |||||||||

Technique | Surface Finish | Grade Series | Thickness(mm) | Width(mm) | |||||

Hot Rolled | No.1/2E | 201/202/304/316 | 2.2-12.0 | 20-850 | 1000 | 1219 | 1240 | 1250 | 1500 |

Cold Rolled | 2B | 201/202/304/316 | 0.25-3.0 | √ | √ | √ | √ |

| √ |

|

| 410S/430 | 0.25-2.0 | √ | √ | √ | √ | √ | √ |

| No.4/Hairline/SB | 201/202/304/316 | 0.25-3.0 | √ | √ | √ | √ |

|

|

|

| 410S/430 | 0.25-2.0 | √ | √ | √ | √ | √ |

|

| BA | 201/202/304/316 | 0.2-1.8 | √ | √ | √ | √ | √ |

|

|

| 410S/430 | 0.25-2.0 | √ | √ | √ | √ |

|

|

| 2BA | 410S/430 | 0.25-2.0 | √ | √ | √ | √ |

| |

Specification | |||

Type | Stainless Steel Sheet/ Stainless Steel Plate | ||

Thickness | 0.2-50mm | ||

Length | 2000mm,2438mm,3000mm,5800mm,6000mm,12000mm,etc | ||

Width | 40mm-600mm,1000mm,1219mm,1500mm,1800mm,2000mm,2500mm, 3000mm, 3500mm, etc | ||

Standard | ASTM, AISI, JIS, DIN, EN | ||

Surface | BA/2B/NO.1/N0,4/4K/HL/8K/Embossed | ||

Application | Architecture, Decoration, Kitchenware, Home Appliance, Medical Equipment, Petroleum, etc | ||

Certification | IS0, SGS. | ||

Technique | Cold Rolled / Hot Rolled | ||

Edge | Mill Edge / Silt Edge | ||

Quality | Mill Test Certificate supplied with the shipment, third part inspection is acceptable | ||

Grade (ASTM/UNS) | 201,304,304L,321,316,316L317L,347H,309S,3105,904L,S32205,2507,254SM0S,32760,253MA, NO8926 | ||

Grade(EN) | 1.4301,1.4307,1.4541,1.4401,1.4404,1.4571,1.4438,1.4539,1.4547,1.4529,1.4562,1.4410,1.4878,1.4845,1.4828,1.4876,2.4858,2.4819 | ||

Done through harsh brushing which makes it smooth and taut. This silky smooth addition helps in fingerprint resistance hence this can be used well on decorative and architectural applications that need both beauty and toughness.

The use of abrasive particles that are blasted onto the surface gives a rough, matte appearance. It has a unique attractive appearance that currently makes it very popular, hence suitable for use in any application where beauty plays the leading role.

Polishing leaves the stainless steel surfaces with a glossy, mirror-like appearance and incorporates decorative as well as architectural elements of style. These design tweaks offer an artistic look that is distinguished enough for usage in a variety of scenarios.

It is a smooth, quiet finish achieved by either brushing or chemical treatments and has very little gloss. Structured with understated sophistication and a fingerprint-averse surface, it’s quite an all-rounder, taking a beautiful form that meets functionality very well across its uses.

This pattern is produced by using high speed on the steel surface and plunging it into acid for etching. The granulated appearance of stainless steel adds something special to its use for architectural and artistic purposes where an interesting surface is required.

This is obtained by chemical or laser etching on it to develop patterns or designs over the surface. It's great for decorative purposes, where it gives a visually exciting and customized look; hence very popular in niche areas of stainless steel finish.

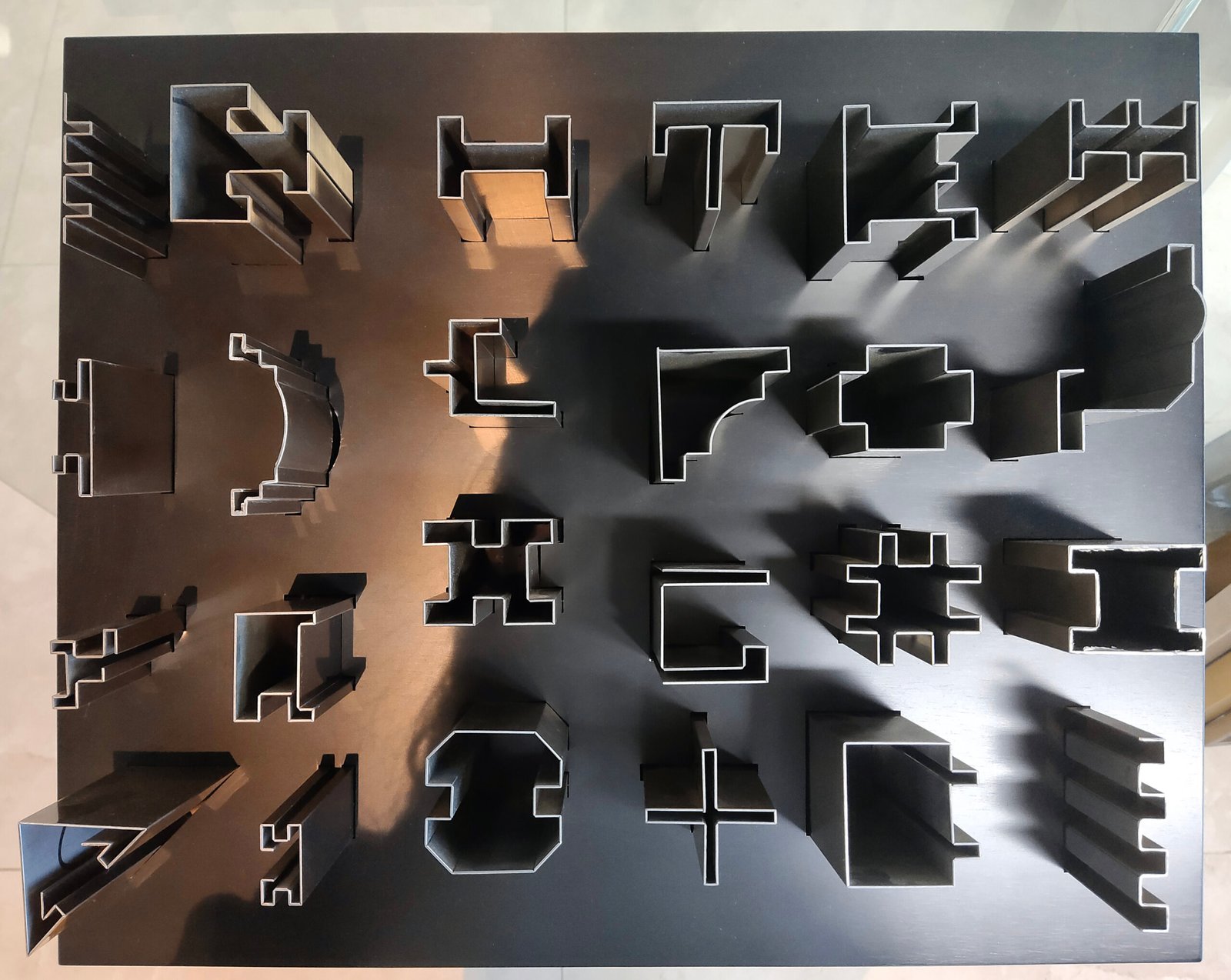

Stainless Steel Tubes

In addition to flat-rolled products, XYC Metalworks offers a wide range of stainless steel tubes for structural support, fluid conveyance, and decorative applications. Our tubes are also available in Grades 304 and 316, ensuring consistent and exceptional quality.

Main Types

- Seamless Tube

Process: Manufactured from a solid steel billet through a hot or cold drawing process, resulting in no welded seam.

Properties: Capable of withstanding extremely high pressure and has a uniform structure. Ideal for high-pressure, high-temperature, and highly corrosive environments.

Standards: ASTM A213 (Heat Exchanger), ASTM A269 (General)

- Welded Tube

Process: Formed from a stainless steel coil and joined with a longitudinal or spiral weld.

Properties: Highly efficient to produce, cost-effective, and available in a wider range of sizes with more uniform wall thickness. The primary choice for structural and decorative applications.

Standards: ASTM A554 (Decorative), ASTM A249 (Boiler/Heat Exchanger), ASTM A269 (General), ASTM A778 (Large Diameter)

Tube Specifications

Parameter | Details |

Shape | Round, Square, Rectangular |

Outer Diameter (OD) | 6mm – 305mm (or larger, depending on type) |

Wall Thickness (WT) | 0.5mm – 50mm (depending on type) |

Length | Standard 6 meters (Custom cutting available) |

Surface | Mill Finish (2B), Bright Annealed (BA), Polished (180, 320, 400, 600 Grit) |

Grade | 304, 304L, 316, 316L |

Applications | Architectural railings, handrails, door frames, sanitary food processing, chemical pipelines, medical devices, automotive exhaust systems, heat exchangers. |

Why Choose XYC Metalworks?

Superior Corrosion Resistance: Our stainless steel products (especially Grade 316) withstand the harshest environments, making them perfect for industrial and coastal applications.

Strength & Durability: Stainless steel’s high tensile strength ensures long-term reliability in structural and industrial applications.

Hygienic Properties: The non-porous surface does not harbor bacteria and is easy to clean, making it the top choice for the food, beverage, and medical industries.

Aesthetic Versatility: With finishes from mirror-polish to brushed, stainless steel offers limitless possibilities for modern architecture and interior design.

Ease of Fabrication: Stainless steel is readily welded, cut, and formed, allowing it to meet the precise needs of any custom project.

Low Maintenance & Recyclable: Stainless steel is easy to clean and requires minimal upkeep. It is also 100% recyclable, making it an environmentally friendly material.

Frequently Asked Questions (FAQs)

Q1: What are the primary applications for custom stainless steel sheets & plates?

A: Custom stainless steel sheets are extensively utilized in modern architecture for roofing, curtain walls, and luxury interior decoration. They are also essential in the automotive and aerospace industries. Stainless steel plates (6mm and thicker) are engineered for heavy-duty structural applications requiring high strength, such as bridges, storage tanks, and industrial machinery.

Q2: How do I choose between Grade 304 and Grade 316 for stainless steel fabrication?

A: Grade 304 is the most versatile and cost-effective option for general environments, offering excellent formability for standard stainless steel fabrication projects. However, if your project is located in coastal areas or exposed to chlorides and harsh chemicals, Grade 316 stainless steel is required due to its added molybdenum, which provides superior corrosion and pitting resistance.

Q3: What premium stainless steel finishes does XYC Metalworks offer?

A: We provide a comprehensive range of stainless steel finishes to meet diverse aesthetic and functional needs, including Brushed (Hairline), 8K Mirror Polish, Sandblasted, Satin, Vibration, and custom Etched patterns. These finishes ensure that your decorative profiles or architectural panels achieve the perfect visual impact.

Q4: Can your stainless steel sheets and tubes be customized to specific project requirements?

A: Absolutely. XYC Metalworks provides end-to-end 304 & 316 stainless steel fabrication services. We offer complete customization, including precision cutting-to-size, CNC bending, professional welding, and bespoke surface finishing to ensure every stainless steel sheet and tube meets your project’s exact dimensions and design intent.

Q5: What is the best way to clean and maintain architectural stainless steel?

A: Routine maintenance is simple: use a mild detergent and warm water to preserve the surface. It is critical to avoid any cleaners containing chlorine (bleach) or abrasive tools like steel wool, as these can scratch the stainless steel finishes and compromise the material’s natural corrosion resistance.

Q6: Is stainless steel considered an environmentally friendly building material?

A: Yes, stainless steel is a highly sustainable choice for modern construction. It is 100% recyclable and is often manufactured using a high percentage of recycled material. Its exceptional longevity reduces resource consumption over the building’s lifecycle, making it a cornerstone of green architectural stainless steel design.

Q7: What is the fundamental technical difference between a stainless steel sheet and a plate?

A: The primary distinction lies in the thickness: material under 6mm thick is categorized as a stainless steel sheet, while material 6mm and thicker is classified as a stainless steel plate. This thickness difference determines their application, ranging from light-duty decorative cladding to heavy-duty structural engineering.

Q8: Are your stainless steel products suitable for high-exposure outdoor use?

A: Yes, they are ideal for outdoor environments. Thanks to its excellent weather and corrosion resistance, our architectural stainless steel (particularly Grade 316) is a preferred material for outdoor installations, marine hardware, and coastal architecture.

Q9: How can I effectively prevent stainless steel from rusting or corroding?

A: While stainless steel is naturally rust-resistant, prevention starts with selecting the correct grade—such as 316 stainless steel for high-chloride or marine environments. Additionally, keeping the surface clean and avoiding prolonged contact with corrosive chemicals or abrasive carbon steel tools will ensure optimal performance.

Q10: What is the difference between seamless and welded architectural stainless steel tubes?

A: Seamless tubes are manufactured from a solid billet and have no weld seam, allowing them to withstand higher pressures. Welded architectural stainless steel tubes are more cost-effective, offer a wider range of sizes, and provide more uniform wall thickness, making them the superior choice for most structural and decorative applications.

Why Choose XYC Metalworks for Your Stainless Steel Project?

XYC Metalworks provides PVD-coated stainless steel products through quality craft, fabrication, and control. We offer flexible solutions, finishes, and worldwide supply to guarantee your project will have a durable appearance, style, and performance.

Industry Expertise

Our highly skilled team knows how to optimally produce the metal finish and guarantees to create a finish that is in line with your aspirations.

High-Quality Materials

We employ superior quality metals for captivating and enduring metal finishes giving architectural or interior design projects longevity.

Custom Solutions

The decorative panels can be produced in the preferred or desired hue, surface texture, and weave structure that you desire for your project.

Exceptional Service

Making customers content is always our goal, and effective communication, problem solving, and timely help guarantee a smooth project process.

Sustainable Practices

Such as using environmentally friendly materials, recycling, and reducing waste, to achieve aesthetically attractive and sustainable metal finishes.

Competitive Pricing

Our patina finish services are affordable while still providing high quality and we ensure that our prices are amongst the fairest in the market today.

Start Your Next Iconic Project

Contact our engineering team today to get a custom quote for your project or to schedule a factory tour.

Contact Form

Headquarter (China)

XYC Metalworks Co., Ltd

- No.1 Dashi Industry Zone, Lishui, Nanhai, Foshan, Guangdong, China

- +86 18923114885

- +86 18923114885

- Sales@xycmetalworks.com

- www.xycmetalworks.com