XYC Metalworks

- Lorem donec massaRated 3 out of 5

- Velit aliquet sagittisRated 3 out of 5

- Magna etiam tempor orciRated 3 out of 5

- Tristique et egestas quis ipsumRated 3 out of 5

- Cum sociis natoqueRated 3 out of 5

- Pellentesque elit eget gravidaRated 3 out of 5

Quick Summary

Rhoncus aenean vel elit scelerisque mauris pellentesque pulvinar pellentesque habitant. Ridiculus mus mauris vitae ultricies leo. Ut ornare lectus sit amet. Eu augue ut lectus arcu. Egestas quis ipsum suspendisse ultrices.

Gravida rutrum quisque non tellus orci ac. Egestas dui id ornare arcu odio ut sem nulla. Sed elementum tempus egestas sed sed risus pretium. Lectus sit amet est placerat. Consequat semper viverra nam libero justo laoreet sit amet cursus.

Specs

- Pellentesque: Gravilmusa

- Cum sociis: Natoque

- Tristiquex: Egestas quis ipsum

- Velit aliquet: Sagittis

Pros

- Phasellus vestibulum lorem

- Ridiculus mus mauris vitae

Cons

- Gravida rutrum quisque

- Egestas dui id ornare arcu

PVDF Coated

- Home

- Product Reviews

- PVDF Coated

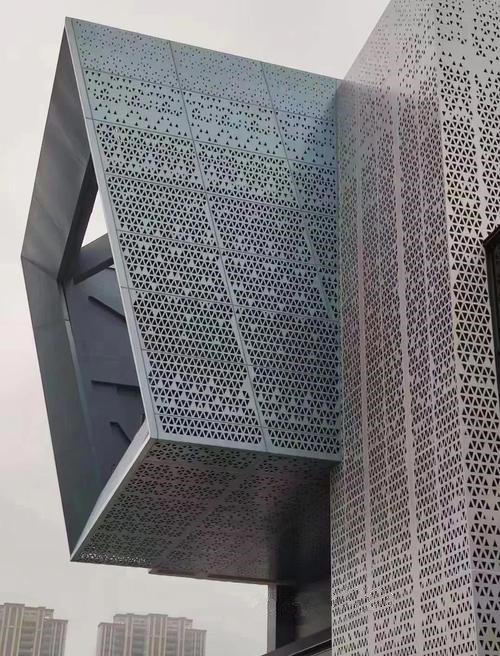

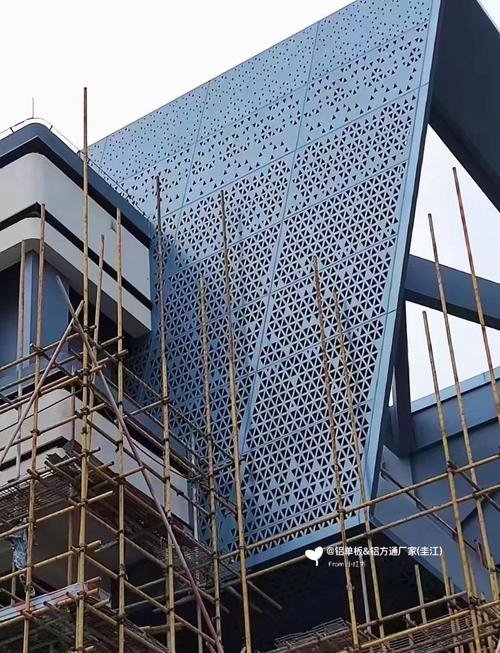

XYC Metalworks: High-Performance Custom PVDF Coated Aluminium Sheets for Architectural Excellence

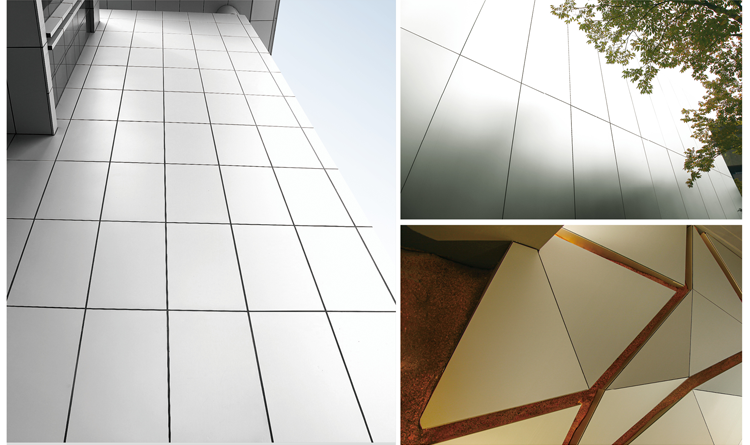

As a leading provider of custom PVDF coated aluminium sheets, XYC Metalworks combines the structural strength of high-grade aluminium with the advanced protection of fluorocarbon paint. Our architectural aluminium cladding solutions are engineered to withstand extreme weathering and UV radiation for over 20 years, making them the premier choice for modern façades, roofing, and curtain walls in challenging environments.

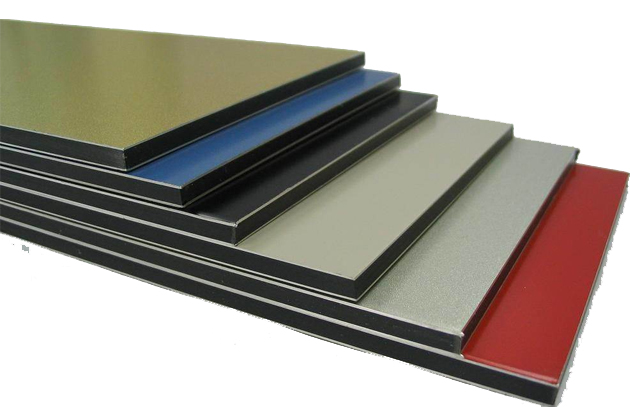

Compared to standard PE-coated aluminium, PVDF-coated sheets typically last over 20 years, making them a durable and reliable material choice for exterior and interior architectural applications. Manufactured in thicknesses from 0.8mm to 5mm, these lightweight yet rigid aluminium sheets are highly versatile and customizable in color, finish, shape, and size to meet the needs of both commercial and residential design projects.

- Brochure Download

Applications

Versatility That Meets Demanding Design Needs

PVDF-coated aluminium sheets are trusted across a wide range of industries due to their excellent formability, weather durability, chemical resistance, and aesthetic flexibility. From building facades and roofing to signage and transportation (including rolling stock like trains and buses), these sheets ensure structural integrity and visual appeal in harsh environments.

PVDF-coated aluminium is a preferred material for exterior wall cladding and façade systems. The coating offers long-term protection against environmental degradation while maintaining a sleek, modern finish.

Roofing Systems

Engineered for resilience, PVDF-coated aluminium roofing sheets offer excellent UV resistance and a long service life. They are ideal for commercial and industrial roofing systems where exposure to the elements is constant.

The high color retention and surface integrity of PVDF coatings make these sheets ideal for vibrant, long-lasting signage and advertising displays.

Modern architectural curtain wall systems benefit from PVDF aluminium’s corrosion resistance, lightweight construction, and superior weatherproofing, ensuring lasting aesthetics and minimal maintenance.

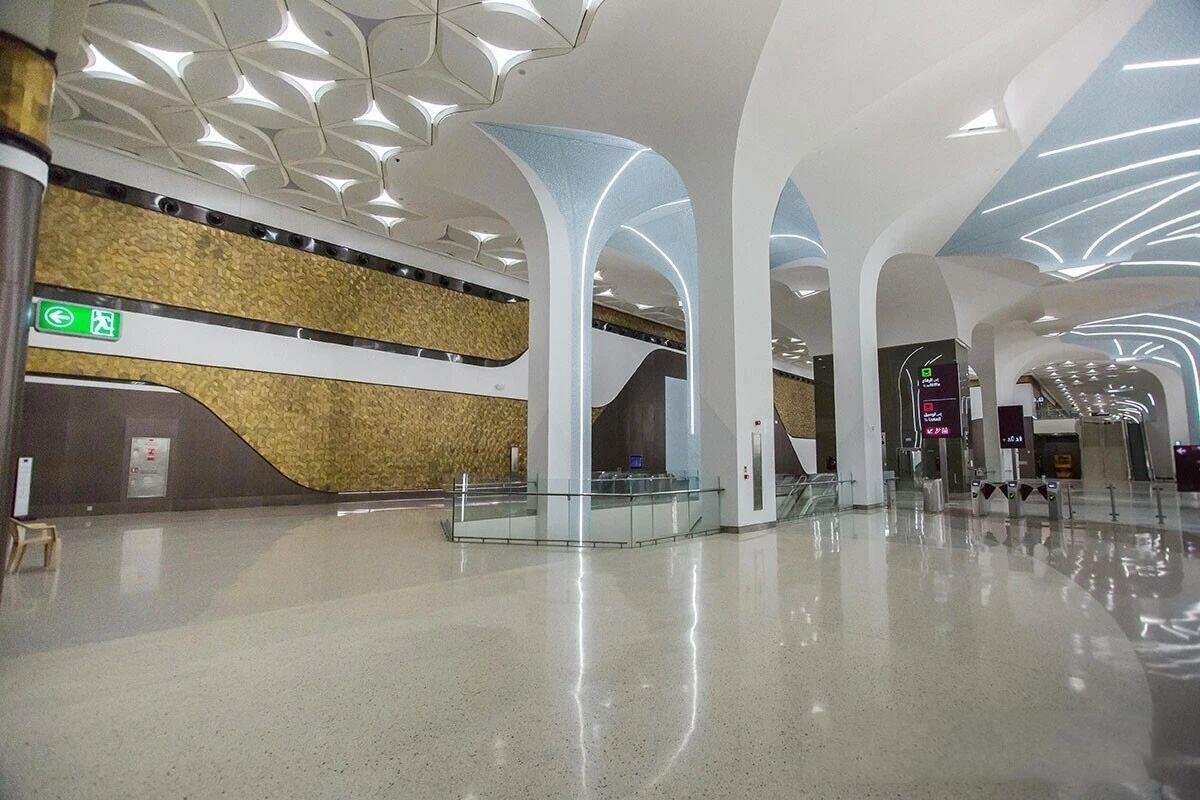

Though commonly used outdoors, PVDF aluminium panels are equally suited for indoor decorative cladding. They offer smooth surfaces and modern aesthetics for lobbies, halls, and feature walls, fitting in with many interior decorations.

PVDF-coated ceiling panels provide long-term durability with minimal discoloration or dirt adhesion, making them ideal for commercial ceilings in offices, airports, and public buildings.

Lightweight, corrosion-resistant, and visually appealing, PVDF-coated aluminium is increasingly used in designer furniture, especially for outdoor settings or high-humidity areas.

Electronic Appliance Panels

For home appliances and electronic enclosures, PVDF coating provides both an elegant, “fancy” finish and enhanced protection against corrosion and environmental exposure.

Product Specifications

Parameter | Details |

Standard | GB/T 24001-2016, GB/T 19001-2016, ASTM, JIS, EN |

Thickness | 0.8mm – 3.0mm |

Width | 30mm – 1850mm (customizable) |

Length | 1220mm – 3000mm (customizable) |

Tolerance | ±1% |

Alloy Grades | 1050, 1060, 1100, 3003, 3105, 5052 |

Processing | Cold Rolled |

Finish | PVDF Powder Coating |

Colors | Champagne, Black, Blue, Silver, Gold, Rose Gold, etc. |

Edge Type | Mill Edge, Slit Edge |

Applications | Facades, Ceilings, Interior Walls, Decorations |

Packaging | PVC film + Waterproof paper + Wooden crate |

Color & Finish Options

Customization to Match Any Design Vision

PVDF-coated aluminium sheets are available in an extensive palette, including solid, metallic, matte, gloss, textured, and brushed finishes. Whether you’re aiming for a modern, industrial look or a warm, decorative tone, our coating technologies can achieve the visual effect you need.

The coating’s durability ensures vivid colors stay bright, resisting fading, chalking, peeling, and scratching. This makes them ideal for projects requiring both high design appeal and long-lasting performance.

Compatible Base Metals

Material Flexibility for a Wide Range of Applications

While aluminium is the most common base metal for PVDF coating due to its light weight and corrosion resistance, the process is also compatible with other substrates to meet various performance and aesthetic needs:

Steel

Applying a PVDF coating to steel surfaces enhances rust resistance and helps them last longer, making it a great solution for structural building use and industrial factory parts.

Stainless Steel

When stainless steel, already loved for its corrosion resistance, receives a PVDF coating, it becomes even more resistant to dangerous environmental conditions and guarantees steady results in hard situations.

Copper

PVDF coating enhances copper’s decorative richness and shine while providing a strong defense against oxidation, significantly increasing the lifespan of copper components.

Galvanized Steel

This combination merges the zinc protection of galvanized steel with the high performance of a PVDF coating. This double-layer approach adds extra strength and makes it robust for a wide range of outdoor applications.

Other Non-Ferrous Metals

The flexibility of PVDF coating extends to other non-ferrous metals, including adding durability and aesthetic finishes to bronze, brass, and nickel for custom design needs.

Key Benefits of PVDF Coated Aluminium Sheets

Superior Weather Resistance: Engineered to endure extreme weather without degradation.

UV Radiation Protection: Ideal for long-term exposure to sunlight.

Architectural Aesthetics: Sleek finishes, rich colors, and modern visual appeal.

Durable Cladding Solution: Long-lasting performance for façades and roofing.

Low Maintenance: Stain-resistant, easy to clean, and fade-resistant, saving on long-term costs.

Versatile Application: From signage and curtain walls to solar energy systems and modern interiors.

High Chemical Resistance: Perfect for industrial, marine, or chemical-prone environments.

Sustainability: 100% recyclable, with a low environmental impact over its lifecycle, supporting green building practices.

Frequently Asked Questions (FAQs)

Q1: What is the main advantage of Custom PVDF Coated Aluminium Sheets over standard PE coating?

A1: PVDF (fluorocarbon) coatings offer significantly higher resistance to UV radiation, chemicals, and pollutants. While PE may fade, PVDF typically lasts over 20 years, ensuring long-term color stability for architectural aluminium cladding.

Q2: Are these sheets suitable for coastal or marine environments?

A2: Yes. Custom PVDF coated aluminium sheets are ideal for marine or industrial areas because the coating provides an exceptional chemical barrier against salt spray and corrosive environmental factors.

Q3: Can XYC Metalworks match specific project colors for PVDF coatings?

A3: Absolutely. We provide an extensive palette including metallic, matte, and gloss finishes, and can custom-match colors to align with your specific branding or architectural vision.

Q4: Is the PVDF coating process environmentally friendly?

A4: Yes. Aluminium is $100\%$ recyclable and the PVDF coating does not affect its recyclability. Our processes support green building practices and energy conservation.

Q5: What are the primary applications for architectural aluminium cladding?

A5: It is widely used for exterior wall façades, curtain wall systems, commercial roofing, and high-visibility signage where durability and aesthetics are critical.

Q6: Can you apply PVDF coating to other metals besides aluminium?

A6: While aluminium is most common, we can apply PVDF coatings to steel, stainless steel, and copper to enhance their corrosion resistance and aesthetic life .

Q7: How much maintenance is required for PVDF coated facades?

A7: Maintenance is minimal. The coating’s smooth surface resists dirt adhesion and staining, requiring only periodic cleaning with water to maintain its “day one” look.

Q8: What thickness is recommended for exterior wall panels?

A8: Depending on the wind load and span, we typically manufacture architectural panels in thicknesses ranging from $2.0\text{ mm}$ to $5.0\text{ mm}$ to ensure rigidity and flatness.

Q9: Does PVDF coating protect against "chalking" and peeling?

A9: Yes. High-quality PVDF resins are specifically designed to resist chalking, peeling, and scratching even after decades of intense solar exposure.

Q10: Is this material suitable for interior high-traffic areas?

A10: Yes. Although engineered for outdoors, its sleek finish and chemical resistance make it a popular choice for luxury lobbies, ceiling systems, and decorative interior features.

Partner with XYC Metalworks

Contact XYC Metalworks today to discuss your project requirements and discover how our PVDF-coated aluminium solutions can deliver long-lasting performance and exceptional aesthetics for your next project.

Industry Expertise

Our highly skilled team knows how to optimally produce the metal finish and guarantees to create a finish that is in line with your aspirations.

High-Quality Materials

We employ superior quality metals for captivating and enduring metal finishes giving architectural or interior design projects longevity.

Custom Solutions

The decorative panels can be produced in the preferred or desired hue, surface texture, and weave structure that you desire for your project.

Exceptional Service

Making customers content is always our goal, and effective communication, problem solving, and timely help guarantee a smooth project process.

Sustainable Practices

Such as using environmentally friendly materials, recycling, and reducing waste, to achieve aesthetically attractive and sustainable metal finishes.

Competitive Pricing

Our patina finish services are affordable while still providing high quality and we ensure that our prices are amongst the fairest in the market today.

Start Your Next Iconic Project

Contact our engineering team today to get a custom quote for your project or to schedule a factory tour.

Contact Form

Headquarter (China)

XYC Metalworks Co., Ltd

- No.1 Dashi Industry Zone, Lishui, Nanhai, Foshan, Guangdong, China

- +86 18923114885

- +86 18923114885

- Sales@xycmetalworks.com

- www.xycmetalworks.com