XYC Metalworks

- Lorem donec massaRated 3 out of 5

- Velit aliquet sagittisRated 3 out of 5

- Magna etiam tempor orciRated 3 out of 5

- Tristique et egestas quis ipsumRated 3 out of 5

- Cum sociis natoqueRated 3 out of 5

- Pellentesque elit eget gravidaRated 3 out of 5

Quick Summary

Rhoncus aenean vel elit scelerisque mauris pellentesque pulvinar pellentesque habitant. Ridiculus mus mauris vitae ultricies leo. Ut ornare lectus sit amet. Eu augue ut lectus arcu. Egestas quis ipsum suspendisse ultrices.

Gravida rutrum quisque non tellus orci ac. Egestas dui id ornare arcu odio ut sem nulla. Sed elementum tempus egestas sed sed risus pretium. Lectus sit amet est placerat. Consequat semper viverra nam libero justo laoreet sit amet cursus.

Specs

- Pellentesque: Gravilmusa

- Cum sociis: Natoque

- Tristiquex: Egestas quis ipsum

- Velit aliquet: Sagittis

Pros

- Phasellus vestibulum lorem

- Ridiculus mus mauris vitae

Cons

- Gravida rutrum quisque

- Egestas dui id ornare arcu

Sandblasted Finish

- Home

- Product Reviews

- Sandblasted Finish

Sandblasted stainless steel sheets—also known as bead-blasted stainless steel—feature a smooth, uniform matte finish achieved through high-pressure abrasion with fine, inert media such as glass beads. This non-directional, low-reflective surface enhances both visual appeal and functional performance, making it an excellent choice for architectural, interior, industrial, and artistic applications.

At XYC Metalworks, we offer this finish in a wide range of thicknesses and premium grades. Thinner sheets are ideal for detailed decorative work, while thicker panels are used where structural integrity is required.

- Brochure Download

Key Applications

Versatile, Durable, and Visually Striking

Bead-blasted stainless steel sheets are prized for their subtle texture, refined aesthetics, and long-lasting performance. From iconic architectural facades to custom signage and furniture, this finish delivers style without compromising strength.

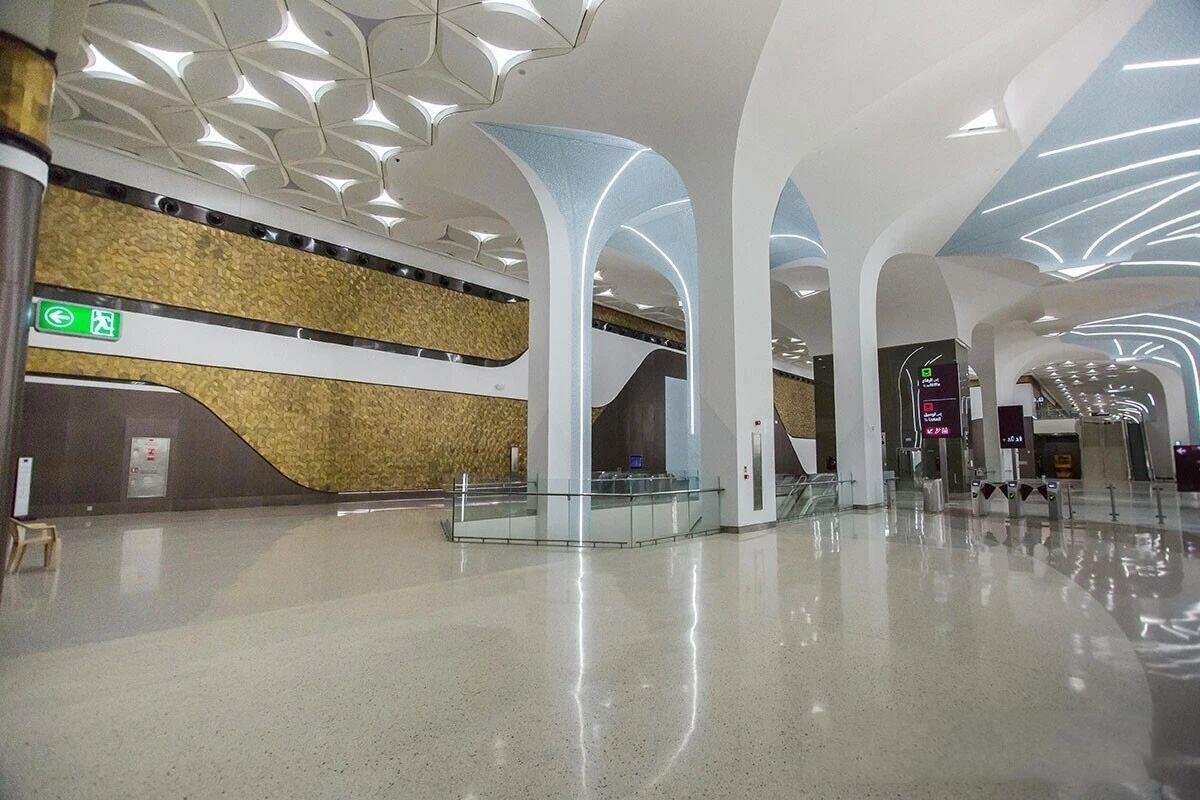

Architectural Cladding: Frequently specified for both interior and exterior architectural cladding. Its muted sheen enhances modern, minimalist, and industrial designs while maintaining corrosion resistance.

Interior Design: Used for wall accents, backsplashes, or feature panels, the textured surface adds depth and sophistication to residential and commercial interiors.

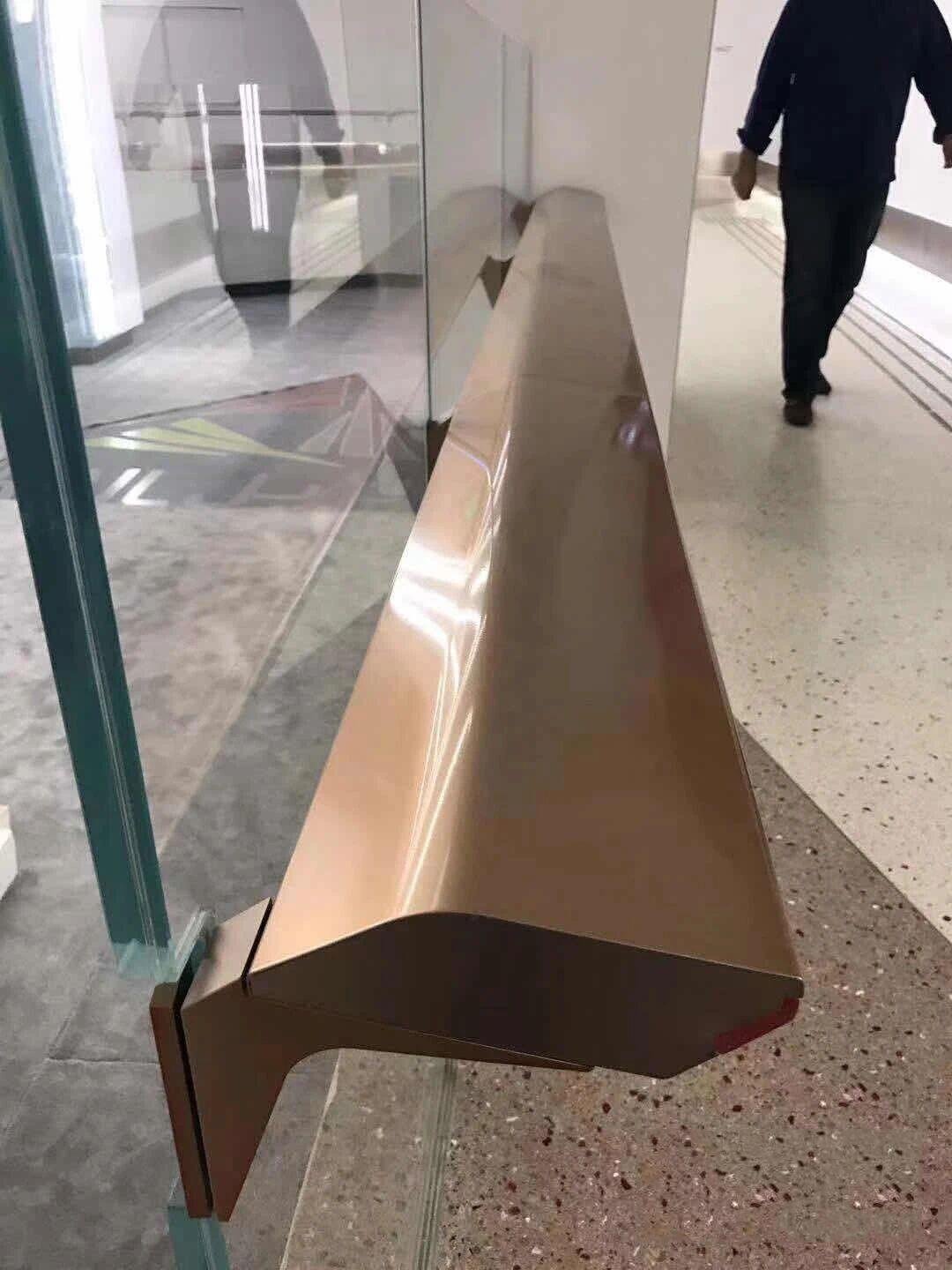

Furniture Fabrication: Favored for its sleek, satin-like appearance and tactile comfort. The finish complements contemporary styles and provides added durability to tabletops and decorative trims.

Signage & Branding: Custom signs and logos made from sandblasted stainless steel exude elegance and professionalism, offering a distinct, eye-catching look.

Art & Sculpture: Embraced by artists for its uniform finish and subtle light diffusion, providing a refined backdrop for contemporary metal art.

Industrial Applications: Suitable for machine housings, enclosures, and heavy-duty panels. The textured surface also reduces glare and wear in industrial environments.

Lighting Fixtures: The diffused surface interacts uniquely with light, reducing harsh reflections and adding dimensionality, making it ideal for custom lighting designs.

Exterior Decorative Elements: For gates, railings, and decorative facades, the matte finish offers visual appeal while minimizing maintenance, oxidation, and weather-induced wear.

Product Specifications

Property | Details |

Standards | “JIS, AISI, ASTM, GB, DIN, EN” |

Thickness | 0.3 mm – 3.0 mm (up to 6 mm available) |

Width | “1000 mm, 1219 mm, 1250 mm, 1500 mm, or custom” |

Length | “2000 mm, 2438 mm, 2500 mm, 3000 mm, 3048 mm, or custom” |

Tolerance | ±1% |

Grades | “201, 304, 316, 430 stainless steel, or aluminum” |

Technique | Cold Rolled |

Finish | Sandblasted (Bead-Blasted) |

Available Colors | “Silver, Gold, Rose Gold, Champagne, Copper, Black, Blue” |

Edge Types | “Mill Edge, Slit Edge” |

Applications | “Cladding, Partitions, Ceilings, Elevators, Interiors” |

Packaging | PVC + Waterproof Paper + Wooden Pallet |

Color Options

Design Freedom in Every Hue

The sandblasted surface’s matte texture reduces glare and allows colors to appear more saturated and refined. Available in a spectrum from neutral silver to bold tones like black, blue, and copper, these finishes (often achieved with PVD coating) support a wide range of aesthetic goals—from modern minimalism to bold contemporary statements.

Material Comparison: 304 vs. 316 Stainless Steel

Choosing the Right Alloy for Your Application

304 Stainless Steel

304 is the most commonly used stainless steel for bead-blasting. It offers excellent corrosion resistance, weldability, and formability, making it suitable for most architectural and decorative applications.

316 Stainless Steel

316 offers enhanced resistance to corrosion—especially in marine, coastal, or chemical-prone environments. It is the preferred choice where performance in harsh conditions is critical.

Other Available Finishes

Beyond bead-blasting, XYC Metalworks also offers:

Brushed (Hairline) Finish: For a linear grain texture with a modern feel.

Satin Finish: Smooth, low-gloss, and fingerprint-resistant.

Mirror Finish: High reflectivity for decorative and luxury applications.

Embossed or Patterned: For 3D visual interest and anti-slip functions.

Key Benefits of Bead-Blasted Stainless Steel

✔ Smooth, Uniform Matte Finish: Achieved through precision glass bead treatment.

✔ Low Reflectivity: Reduces glare and hot spots, enhancing visual comfort.

✔ Scratch Concealment: The non-directional texture helps mask minor scuffs and wear.

✔ Tactile Appeal: An inviting surface that looks and feels refined.

✔ Durability: Maintains structural integrity and corrosion resistance.

✔ Customizable Finish: Varying bead size and intensity for different surface effects.

✔ Low Maintenance: Hides fingerprints and smudges, making it easy to clean.

✔ Versatile Design Compatibility: Fits both contemporary and industrial aesthetics.

Maintenance Tips

How to Keep Your Bead-Blasted Surface Looking Its Best

Clean Regularly: Use a soft cloth and mild detergent.

Avoid Abrasive Tools: Do not use steel wool; use microfiber or a soft sponge.

Prevent Water Spots: Dry the surface thoroughly after cleaning.

Use Neutral Cleaners: Avoid harsh, acidic, or alkaline chemicals.

Apply Protective Coatings: Consider this for installations in corrosive environments.

Remove Stains Promptly: Clean spills immediately to prevent discoloration.

Proper care ensures the beauty and longevity of the sandblasted finish for years to come.

Frequently Asked Questions (FAQs)

Q1: What is sandblasted stainless steel?

A: Sandblasted stainless steel is a material treated with high-speed abrasive media, such as glass beads, to create a uniform, matte, and non-reflective finish with enhanced texture and visual appeal. This process is also commonly referred to as bead-blasting.

Q2: What are the main advantages of bead-blasted finishes?

A: Key benefits include a sophisticated modern matte aesthetic, significantly reduced glare and hot spots, excellent scratch concealment, a refined tactile feel, and high design versatility across contemporary and industrial styles.

Q3: Is sandblasted stainless steel resistant to corrosion and scratches?

A:Yes, particularly when using 304 or 316 grades, the surface offers high corrosion resistance. Furthermore, the non-directional matte texture is highly effective at masking minor scuffs, everyday marks, and wear.

Q4: Can the surface texture of sandblasted sheets be customized?

A: es, variables such as bead size, blasting pressure, and post-processing treatments like PVD coloring allow for a wide range of custom surface textures, intensities, and visual effects tailored to your design vision.

Q5: How does a sandblasted finish compare to mirror or brushed finishes?

A: Unlike highly reflective mirror finishes or linear-grained brushed textures, sandblasted stainless steel provides a uniform, non-directional matte surface that diffuses light softly, making it ideal for subtle or minimalist designs.

Q6: What are the common applications for sandblasted stainless steel?

A: It is widely specified for interior and exterior architectural cladding, decorative wall panels, elevator interiors, signage, bespoke furniture fabrication, and high-end lighting fixtures .

Q7: Is it difficult to clean and maintain sandblasted surfaces?

A: No, the matte finish hides fingerprints and smudges exceptionally well. Routine maintenance simply requires cleaning with mild soap, warm water, and a soft microfiber cloth to preserve its beauty.

Q8: Which stainless steel grades are available for sandblasting?

A: XYC Metalworks provides sandblasted finishes in 304, 316, 201, and 430 stainless steel grades. 304 is ideal for most architectural uses, while 316 is recommended for harsh or coastal environment.

Q9: Does XYC Metalworks offer colored sandblasted stainless steel?

A: Yes, we offer an extensive palette including Silver, Gold, Rose Gold, Champagne, Copper, Black, and Blue. These long-lasting colors are typically achieved using advanced PVD (Physical Vapor Deposition) coating technology.

Q10: What factors should I consider when specifying this finish?

A: ou should consider the project environment (indoor vs. outdoor to choose 304 or 316), the required sheet thickness (from 0.3 mm to 6 mm), and whether custom PVD colors are needed for your specific branding or design goals.

Need help choosing the right finish for your next project?

Contact XYC Metalworks for expert consultation, samples, or custom fabrication support.

Industry Expertise

Our highly skilled team knows how to optimally produce the metal finish and guarantees to create a finish that is in line with your aspirations.

High-Quality Materials

We employ superior quality metals for captivating and enduring metal finishes giving architectural or interior design projects longevity.

Custom Solutions

The decorative panels can be produced in the preferred or desired hue, surface texture, and weave structure that you desire for your project.

Exceptional Service

Making customers content is always our goal, and effective communication, problem solving, and timely help guarantee a smooth project process.

Sustainable Practices

Such as using environmentally friendly materials, recycling, and reducing waste, to achieve aesthetically attractive and sustainable metal finishes.

Competitive Pricing

Our patina finish services are affordable while still providing high quality and we ensure that our prices are amongst the fairest in the market today.

Start Your Next Iconic Project

Contact our engineering team today to get a custom quote for your project or to schedule a factory tour.

Contact Form

Headquarter (China)

XYC Metalworks Co., Ltd

- No.1 Dashi Industry Zone, Lishui, Nanhai, Foshan, Guangdong, China

- +86 18923114885

- +86 18923114885

- Sales@xycmetalworks.com

- www.xycmetalworks.com