XYC Metalworks

- Lorem donec massaRated 3 out of 5

- Velit aliquet sagittisRated 3 out of 5

- Magna etiam tempor orciRated 3 out of 5

- Tristique et egestas quis ipsumRated 3 out of 5

- Cum sociis natoqueRated 3 out of 5

- Pellentesque elit eget gravidaRated 3 out of 5

Quick Summary

Rhoncus aenean vel elit scelerisque mauris pellentesque pulvinar pellentesque habitant. Ridiculus mus mauris vitae ultricies leo. Ut ornare lectus sit amet. Eu augue ut lectus arcu. Egestas quis ipsum suspendisse ultrices.

Gravida rutrum quisque non tellus orci ac. Egestas dui id ornare arcu odio ut sem nulla. Sed elementum tempus egestas sed sed risus pretium. Lectus sit amet est placerat. Consequat semper viverra nam libero justo laoreet sit amet cursus.

Specs

- Pellentesque: Gravilmusa

- Cum sociis: Natoque

- Tristiquex: Egestas quis ipsum

- Velit aliquet: Sagittis

Pros

- Phasellus vestibulum lorem

- Ridiculus mus mauris vitae

Cons

- Gravida rutrum quisque

- Egestas dui id ornare arcu

Gratings

- Home

- Product Reviews

- Gratings

We offer precision-engineered stainless steel grating and aluminum grating systems where form follows function. Our custom-made SS grating products are designed for functionality, performance, and visual integration, taking the durability and versatility of industrial and architectural applications one step further.

Whether for industrial flooring, architectural detailing, or drainage systems, our metal gratings are built to last. We strive to achieve grating solutions that combine innovation with practicality, exceeding standards in strength and corrosion resistance to remain durable even under the harshest conditions.

- Brochure Download

Why Professionals Trust Our Grating Systems

We provide solutions to the industry’s most common challenges:

Challenge | Our Solution |

High-load areas with exposure to wear | Welded and swaged grating with reinforced load-bearing capacity. |

Demanding design or size constraints | Fully customizable widths, lengths, and bar configurations. |

Risk of corrosion in marine/chemical zones | 304/316 stainless steel or anodized aluminium options available. |

Safety and drainage requirements | Slip-resistant surface treatments and open-grid formats for fluid flow. |

Project deadlines and volume supply | Efficient manufacturing and batch delivery with labeled packaging. |

Why Choose Us for Custom Grating?

Expertise

With years of experience, we are a leading name in the industry, popular for our integrity and competence in custom-made stainless steel gratings tailored to performance and appearance.

Customization

Immerse in endless possibilities. Choose exact bar spacing, size, pattern, finish, and load-bearing capacity to meet your specific structural and aesthetic goals.

Quality Assurance

Our dedication to quality is displayed in our finicky production process. All gratings undergo multi-stage inspections for weld quality, surface integrity, and tolerance control.

Durability

Engineered for longevity. Our gratings are made to last, resisting corrosion, rust, and abrasion. They deliver long-term reliability in wet, hot, corrosive, and high-load conditions.

On-Time Delivery

We understand that deadlines are critical. Our efficient manufacturing, modular production, and smooth logistics supply your custom grating on time, minimizing potential project delays.

Client Support

Customer satisfaction is our number one goal. We strive to exceed your expectations at all stages, from first consultation to post-delivery follow-up.

Sustainability

Sustainability is our priority. Our gratings are made from 100% recyclable materials, supporting LEED, green building goals, and ensuring project sustainability.

Technical Features at a Glance

Slip-resistant top surface for safety

Available in flat bar, I-bar, or serrated types

Load-bearing bar spacing per EN/ASTM standards

Finished in brushed, bead-blasted, PVD, or anodized

Bolt-down, weldable, or clip-in mounting options

Grating Product Categories

Explore our wide range of SS Grating products that offer different features appropriate for varied situations.

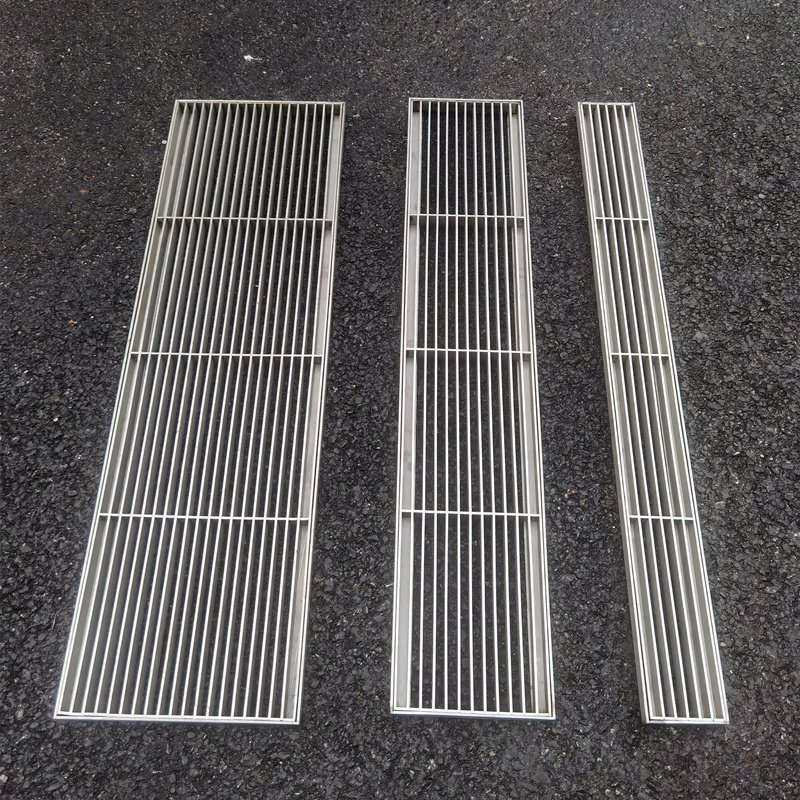

Stainless Steel Welded Grating

Ideal for industrial and heavy-load zones, welded gratings are extremely strong and stable. The welded construction promotes durability and resists deformation, which is important for walkways, platforms, and all high-traffic areas requiring super load-bearing capacity.

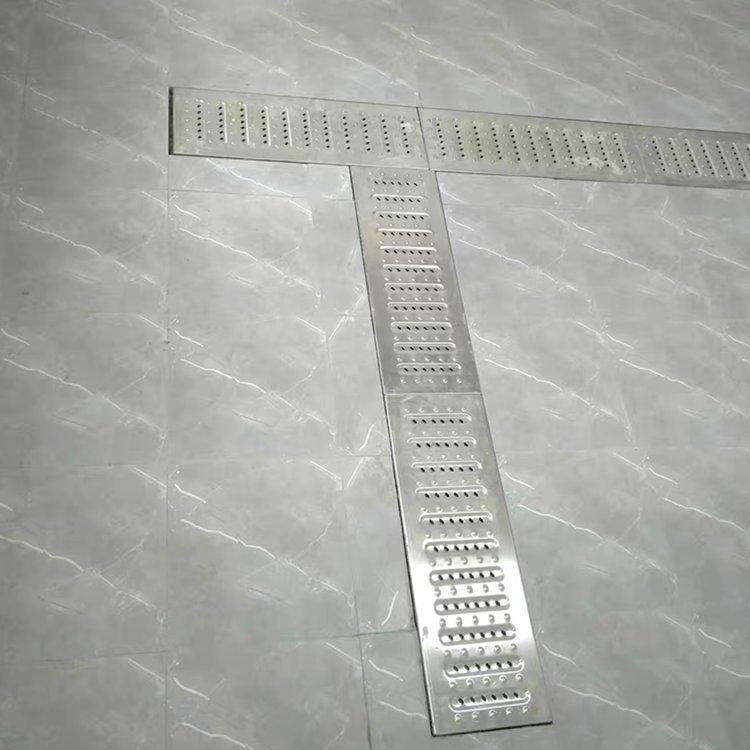

Stainless Steel Press-Locked Grating

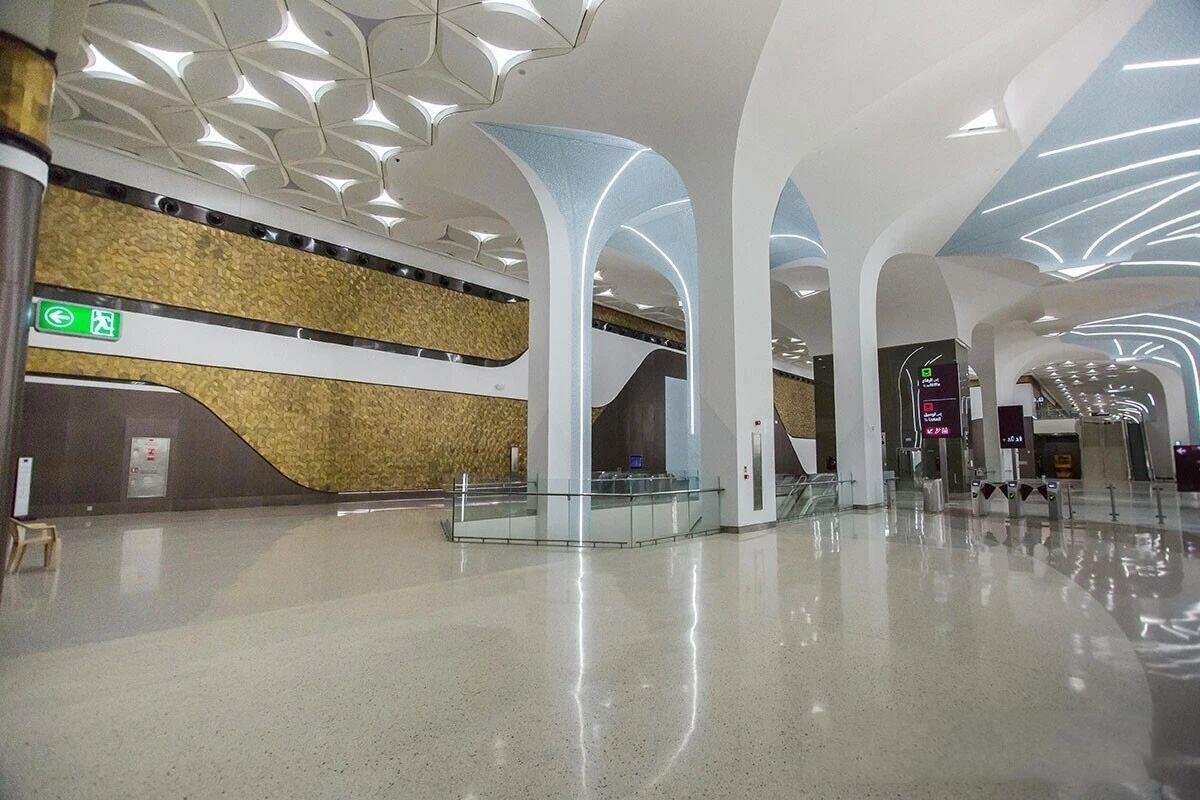

Designed for architectural spaces and urban infrastructure, this grating uses a clean, flush-locking design and robust connection method. Popular for modern elements and decorative accents in commercial and public spaces when sophistication is in demand.

Stainless Steel Swaged Grating

This type combines a lightweight structure with high strength, balancing weight and performance. It provides superior resistance to shearing forces and torsion, making it suitable for catwalks, walkways, and structural platforms demanding versatility.

Aluminium Grating

Lightweight and corrosion-resistant. Perfect for coastal projects, rooftops, ventilation areas, and any space requiring a high strength-to-weight ratio.

Application Areas

The versatility of stainless steel grating makes it valuable to a wide array of industries.

Industrial Flooring: Non-slip or perforated gratings used in plants, factories, and refineries, providing a solid walking surface that allows for ventilation and drainage.

Food & Beverage: Corrosion-proof and easy-to-clean flooring, drainage, and machine access decks for commercial kitchens and food processing plants.

Water Treatment: Walkways, catwalks, and platforms above tanks, basins, and treatment zones, offering resistance to chemicals and wet environments.

Marine Environments: Used on piers, docks, bridges, and ship decks, offering ideal resistance to saltwater corrosion and heavy-weather conditions.

Architecture & Construction: Used as steps, fences, partitions, handrails, and decorative grilles, harmonizing form and function in modern design.

Oil & Gas: Stair treads, platforms, and walkways on offshore rigs, refineries, and petrochemical plants where exposure to corrosive substances is common.

Transportation: Used in bridges, highways, tunnels, and airports for walkways, drains, and safety barriers.

Security Sites: Used for security fencing and perimeter barriers in high-security establishments due to its toughness and strength.

Power Plants: Access zones, walkways, and platforms near turbines, boilers, and electrical rooms that operate under high-temperature conditions.

Frequently Asked Questions (FAQs)

Q1: What is stainless steel grating?

A1: Stainless steel grating is a versatile mesh structure made of stainless steel bars, widely used in industrial, commercial, and architectural environments for flooring, platforms, walkways, and drainage systems.

Q2: What are the advantages of stainless steel grating?

A2: Its primary advantages are extreme durability, high strength, and superior resistance to corrosion, rust, and chemicals. It is also low-maintenance, long-lasting, and 100% recyclable.

Q3: What are the different types of stainless steel grating?

A3: The main types are Welded (for heavy industrial loads), Press-Locked (for architectural and public spaces), and Swaged (for a high strength-to-weight ratio, like catwalks).

Q4: How do I choose the right grating for my project?

A4: You should consider factors like load-bearing requirements, environmental conditions (e.g., chemicals, saltwater), aesthetic goals, and safety needs (like slip-resistance). A consultation with a grating specialist can help you select the right type.

Q5: What environments are best for stainless vs aluminium grating?

A5: Stainless steel is best for heavy-duty industrial, chemical, marine, and food-grade applications. Aluminium is ideal for lightweight needs or coastal designs where corrosion resistance is key but the load is lower.

Q6: Can stainless steel grating be customized?

A6: Absolutely. We offer full customization of dimensions, bar spacing, thickness, patterns, finishes, and load-bearing capacities to match your specific needs and design inclinations.

Q7: How is grating installed?

A7: Installation methods vary. Gratings can be bolted down, welded into place, or attached using specific clips and fasteners, depending on the floor type and structural needs.

Q8: What maintenance is required for stainless steel grating?

A8: Minimal. Regular cleaning with mild detergent and water is usually all that is needed to maintain its appearance and function. Frequent checks for any damage can help extend its lifespan.

Q9: Are the gratings slip-resistant?

A9: Yes. We offer serrated or embossed top surfaces for enhanced anti-slip performance, which is critical in wet or oily environments.

Q10: What is the lifespan of stainless steel grating?

A10: With proper installation and material selection (e.g., 316L for coastal use), stainless steel grating can easily last 20 to 50 years, depending on the exposure and use.

Bring Your Vision to Life

Whether you’re designing a landmark for a city plaza, commemorating a legacy, or adding bold elegance to your space, our custom metal sculptures offer the perfect blend of artistry, engineering, and endurance.

Contact us today to begin your sculpture project—and make a statement that lasts generations.

Industry Expertise

Our highly skilled team knows how to optimally produce the metal finish and guarantees to create a finish that is in line with your aspirations.

High-Quality Materials

We employ superior quality metals for captivating and enduring metal finishes giving architectural or interior design projects longevity.

Custom Solutions

The decorative panels can be produced in the preferred or desired hue, surface texture, and weave structure that you desire for your project.

Exceptional Service

Making customers content is always our goal, and effective communication, problem solving, and timely help guarantee a smooth project process.

Sustainable Practices

Such as using environmentally friendly materials, recycling, and reducing waste, to achieve aesthetically attractive and sustainable metal finishes.

Competitive Pricing

Our patina finish services are affordable while still providing high quality and we ensure that our prices are amongst the fairest in the market today.

Start Your Next Iconic Project

Contact our engineering team today to get a custom quote for your project or to schedule a factory tour.

Contact Form

Headquarter (China)

XYC Metalworks Co., Ltd

- No.1 Dashi Industry Zone, Lishui, Nanhai, Foshan, Guangdong, China

- +86 18923114885

- +86 18923114885

- Sales@xycmetalworks.com

- www.xycmetalworks.com