XYC Metalworks

- Lorem donec massaRated 3 out of 5

- Velit aliquet sagittisRated 3 out of 5

- Magna etiam tempor orciRated 3 out of 5

- Tristique et egestas quis ipsumRated 3 out of 5

- Cum sociis natoqueRated 3 out of 5

- Pellentesque elit eget gravidaRated 3 out of 5

Quick Summary

Rhoncus aenean vel elit scelerisque mauris pellentesque pulvinar pellentesque habitant. Ridiculus mus mauris vitae ultricies leo. Ut ornare lectus sit amet. Eu augue ut lectus arcu. Egestas quis ipsum suspendisse ultrices.

Gravida rutrum quisque non tellus orci ac. Egestas dui id ornare arcu odio ut sem nulla. Sed elementum tempus egestas sed sed risus pretium. Lectus sit amet est placerat. Consequat semper viverra nam libero justo laoreet sit amet cursus.

Specs

- Pellentesque: Gravilmusa

- Cum sociis: Natoque

- Tristiquex: Egestas quis ipsum

- Velit aliquet: Sagittis

Pros

- Phasellus vestibulum lorem

- Ridiculus mus mauris vitae

Cons

- Gravida rutrum quisque

- Egestas dui id ornare arcu

Woven Mesh

- Home

- Product Reviews

- Woven Mesh

At XYC Metalworks, our Woven Wire Mesh is manufactured by interweaving fine metal wires to form various regular mesh patterns (such as plain, twill, or Dutch weave). This process creates a product with uniform apertures, stable structure, high flexibility, and broad applicability.

Woven mesh is renowned for its high tensile strength, superior corrosion resistance, and refined appearance. It is available in stainless steel, carbon steel, and aluminum options. Its unique mesh precision makes it the perfect choice for high-accuracy filtration, security protection, and high-end architectural decoration.

- Brochure Download

Versatile Applications of Woven Wire Mesh: Redefining Modern Design with Precision and Texture

Woven wire mesh unlocks new creative possibilities across architectural and industrial design due to its distinctive mesh texture and precise structure.

Woven Mesh Architectural Facades: Infuse your buildings with elegant texture and a modern geometric aesthetic. These systems provide solar shading and visual softening while maintaining ventilation and natural light diffusion.

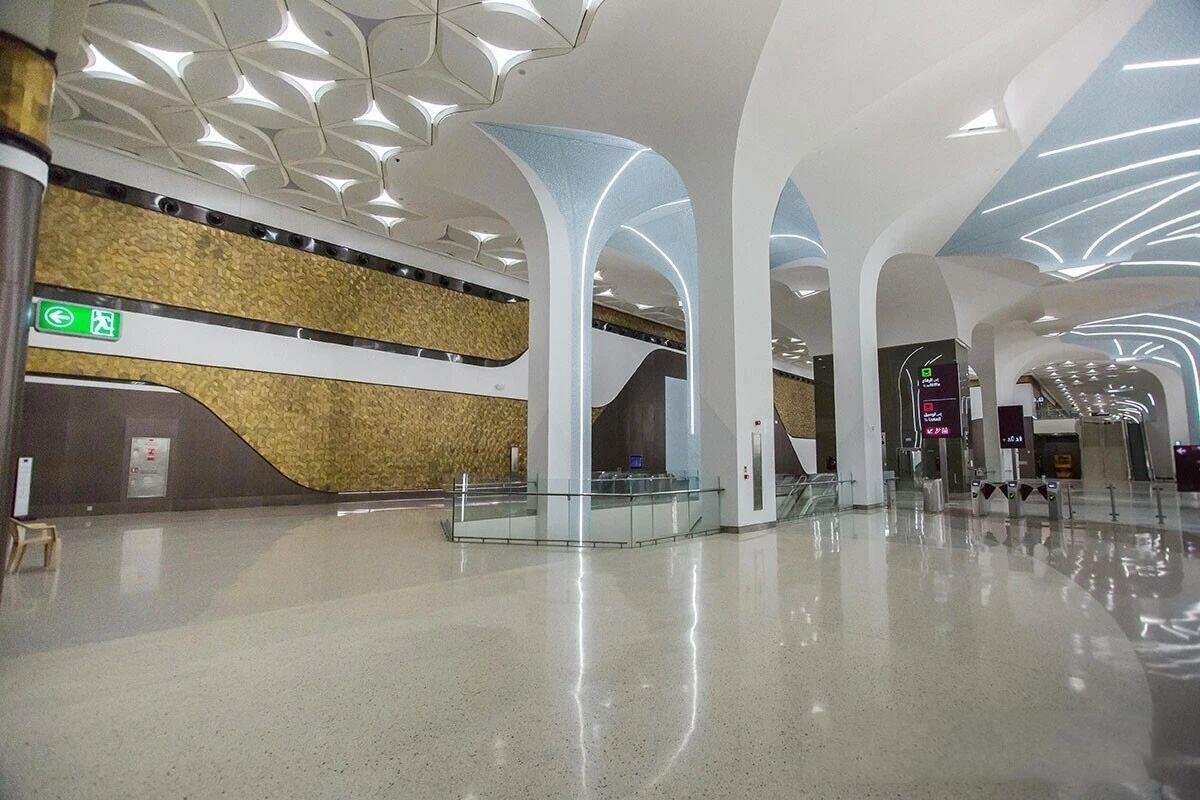

Decorative Ceilings & Suspended Ceilings: Used as ceiling panels, woven mesh offers a smooth texture, concealing utilities while maintaining optimal airflow and acoustic performance.

Interior Partitions & Screens: The flexible mesh design is ideal for interior zone division, stair balustrades, and furniture panels, adding layers and semi-transparency to spaces.

Industrial Filtration & Sieving: Due to its precise aperture sizes, woven mesh is the ideal material for efficient filtration, separation, and sieving in the chemical, food processing, and manufacturing industries.

Security Solutions: Its high tensile strength and durability make it suitable for security fencing, window guards, and protective enclosures.

Product Specifications: Tailored for Technical and Architectural Needs

Parameter | Specification |

Standards | JIS, AiSi, ASTM, GB, DIN, EN (Customizable) |

Wire Diameter/Thickness | 0.3 mm – 3.0 mm |

Width | 300mm – 1850mm (Customizable) |

Length | 300mm – 3000mm (Customizable) |

Tolerance | ±1% |

Materials | Stainless Steel (304, 316, 201, 430), Aluminum, Copper, Brass |

Weave Patterns | Plain Weave, Twill Weave, Dutch Weave |

Surface Finishes | Anodized, Powder Coated, PVD, Mirror Polished, Sandblasted, etc. |

Applications | Facades, Ceilings, Filtration, Security Fencing, Decorative Screens |

Packaging | PVC Film + Waterproof Paper + Wooden Crate |

Surface Finishes: Enhancing Form and Function

Elevate the aesthetics and durability of woven metal mesh with our range of advanced surface treatments:

Powder-Coated Finish: Achieve vibrant, weather-resistant color and added corrosion protection. Electrostatic application ensures a uniform coating suitable for indoor and outdoor architectural use.

Anodized Finish: Add a refined metallic appearance with improved resistance to oxidation and wear. Anodizing enhances durability while maintaining a sleek, modern, metallic look.

PVD-Coated Finish: For a premium, scratch-resistant surface, our PVD (Physical Vapor Deposition) finish delivers rich metallic tones with unmatched longevity, color stability, and toughness.

Material Comparison: Aluminum vs. Stainless Steel Woven Mesh

Selecting the right material depends on your design goals and environmental conditions:

Aluminum Woven Mesh: Lightweight, highly formable, and naturally corrosion-resistant. It is ideal for weight-sensitive installations or projects requiring complex, curved designs, maintaining structural reliability.

Stainless Steel Woven Mesh: Built for durability, stainless steel expanded mesh resists harsh weather and corrosive environments. It offers superior mechanical strength, making it ideal for security applications, industrial filtration, and marine environments.

Choosing the Right Fit: Aluminum suits lightweight, economical projects; stainless steel excels in strength and durability in demanding environments. Both options can be customized with various finishes to meet your performance and aesthetic needs.

Performance Benefits in Architectural and Industrial Applications

Woven metal mesh is an intelligent choice for modern architecture and industry, delivering exceptional visual impact and long-term performance:

High Mesh Precision: The woven structure ensures a highly consistent aperture size, providing high efficiency for industrial filtration and separation.

Dynamic Texture & Aesthetics: The woven patterns add unique texture and depth to facades and interior spaces, creating a sophisticated translucent effect.

Enhanced Ventilation & Light Control: The open mesh structure supports natural airflow and heat dissipation, while achieving soft daylight diffusion.

Superior Durability: Made from stainless steel or aluminum, it withstands harsh climates, UV exposure, and corrosion.

Customizability: Choose from a wide array of weave patterns, wire diameters, mesh sizes, edge treatments, and finishes to fit any design need.

Security & Privacy: Ideal for partitions, barriers, and fencing, offering visual screening while maintaining strength and visibility.

Sustainability: Both stainless steel and aluminum are highly recyclable. Their use in passive ventilation and daylight control supports sustainable building strategies and energy efficiency.

Frequently Asked Questions (FAQs)

Q1: What are the main differences between Woven Wire Mesh and expanded mesh?

A: Woven wire mesh is manufactured by interweaving individual metal wires to create precise and uniform apertures.

In contrast, expanded mesh is produced by slitting and stretching a single solid sheet, offering high structural strength but less mesh precision than woven wire mesh.

Q2: What common weave patterns are available for Woven Wire Mesh?

A: At XYC Metalworks, we offer several precision patterns, including Plain Weave (the most common for uniform apertures), Twill Weave (offering higher strength for finer meshes), and Dutch Weave (specifically designed for high-precision filtration).

Q3: How do I choose between SS Grade 304 and 316 Woven Wire Mesh?

A: Grade 304 is the standard choice for general and indoor architectural applications.

However, for marine environments, chemical processing, or humid outdoor settings, Grade 316 woven wire mesh is recommended due to its superior corrosion resistance and anti-chloride capabilities.

Q4: Is Woven Wire Mesh suitable for outdoor architectural facades and security?

A: Yes, woven wire mesh made from stainless steel or aluminum is exceptionally durable and weather-resistant.

Its high tensile strength makes it an ideal barrier for security screens and fencing, while its aesthetic texture provides elegant solar shading for building facades.

Q5: What maintenance is required to keep Woven Wire Mesh looking new?

A: Woven wire mesh is a low-maintenance material.

For most architectural applications, regular cleaning with mild soap and water is sufficient to remove surface dust and maintain its refined appearance over time.

Q6: What surface finishes can be applied to decorative Woven Wire Mesh?

A: We provide advanced surface treatments including Powder Coating for vibrant colors, Anodizing for a sleek metallic look, and PVD Coating (Physical Vapor Deposition) for premium, scratch-resistant metallic tones with unmatched longevity.

Q7: Should I choose Aluminum or Stainless Steel Woven Wire Mesh for my project?

A: Aluminum woven wire mesh is lightweight and highly formable, making it perfect for weight-sensitive or curved designs.

Stainless steel woven wire mesh excels in extreme environments requiring maximum mechanical strength and superior durability.

Q8: Can Woven Wire Mesh improve building energy efficiency?

A: Absolutely. Used as architectural facades or window guards, the open structure of woven wire mesh supports natural ventilation and heat dissipation while achieving soft daylight diffusion, which contributes to sustainable building strategies.

Q9: What are the primary industrial applications for precision Woven Wire Mesh?

A: Beyond decoration, its precise aperture sizes make it the ideal material for high-accuracy filtration, separation, and sieving in industries such as food processing, chemical manufacturing, and pharmaceutical production.

Q10: Can XYC Metalworks provide custom specifications for Woven Wire Mesh?

A: Yes. We manufacture woven wire mesh tailored to your technical needs, including customizable wire diameters (0.3 mm – 3.0 mm), mesh patterns, and dimensions that comply with international standards like ASTM, JIS, and EN.

XYC Metalworks — Your Expert Manufacturer of Woven Wire Mesh

At XYC Metalworks, we bring innovation and precision manufacturing to woven wire mesh production. With advanced weaving technology, expert craftsmanship, and a commitment to quality, we deliver reliable solutions for architectural, commercial, and industrial applications.

Partner with XYC Metalworks to realize your design vision with materials built for excellence.

Would you like me to now generate a list of the image file names and their corresponding clean English descriptions (Long-Tail Name and Description) for the Woven Mesh page?

Industry Expertise

Our highly skilled team knows how to optimally produce the metal finish and guarantees to create a finish that is in line with your aspirations.

High-Quality Materials

We employ superior quality metals for captivating and enduring metal finishes giving architectural or interior design projects longevity.

Custom Solutions

The decorative panels can be produced in the preferred or desired hue, surface texture, and weave structure that you desire for your project.

Exceptional Service

Making customers content is always our goal, and effective communication, problem solving, and timely help guarantee a smooth project process.

Sustainable Practices

Such as using environmentally friendly materials, recycling, and reducing waste, to achieve aesthetically attractive and sustainable metal finishes.

Competitive Pricing

Our patina finish services are affordable while still providing high quality and we ensure that our prices are amongst the fairest in the market today.

Start Your Next Iconic Project

Contact our engineering team today to get a custom quote for your project or to schedule a factory tour.

Contact Form

Headquarter (China)

XYC Metalworks Co., Ltd

- No.1 Dashi Industry Zone, Lishui, Nanhai, Foshan, Guangdong, China

- +86 18923114885

- +86 18923114885

- Sales@xycmetalworks.com

- www.xycmetalworks.com