XYC Metalworks

Why We Build it Twice: The Critical Role of the 1:1 Mock-up in Our Process

- Home

- Insights

- Behind the Scenes

- Why We Build it Twice: The Critical Role of the 1:1 Mock-up in Our Process

Table of Contents

In architectural fabrication, the most expensive mistake is the one made on-site. For complex, visionary designs, the leap from a 3D model to a physical landmark is filled with risk. How do you guarantee that a complex, dual-curved facade or a 50,000-piece interior system will install flawlessly?

At XYC Metalworks, our philosophy is simple: We build it twice.

We build it first as a full-scale, 1:1 mock-up in our factory. Only after we’ve solved every problem there, do we build it the second time—for your final project.

Build #1: The Factory Mock-up (De-Risking the Vision)

The 1:1 mock-up is not a “sample”; it’s a dress rehearsal for the entire project. It is the single most important step in translating an architect’s vision into a fabrication-ready plan.

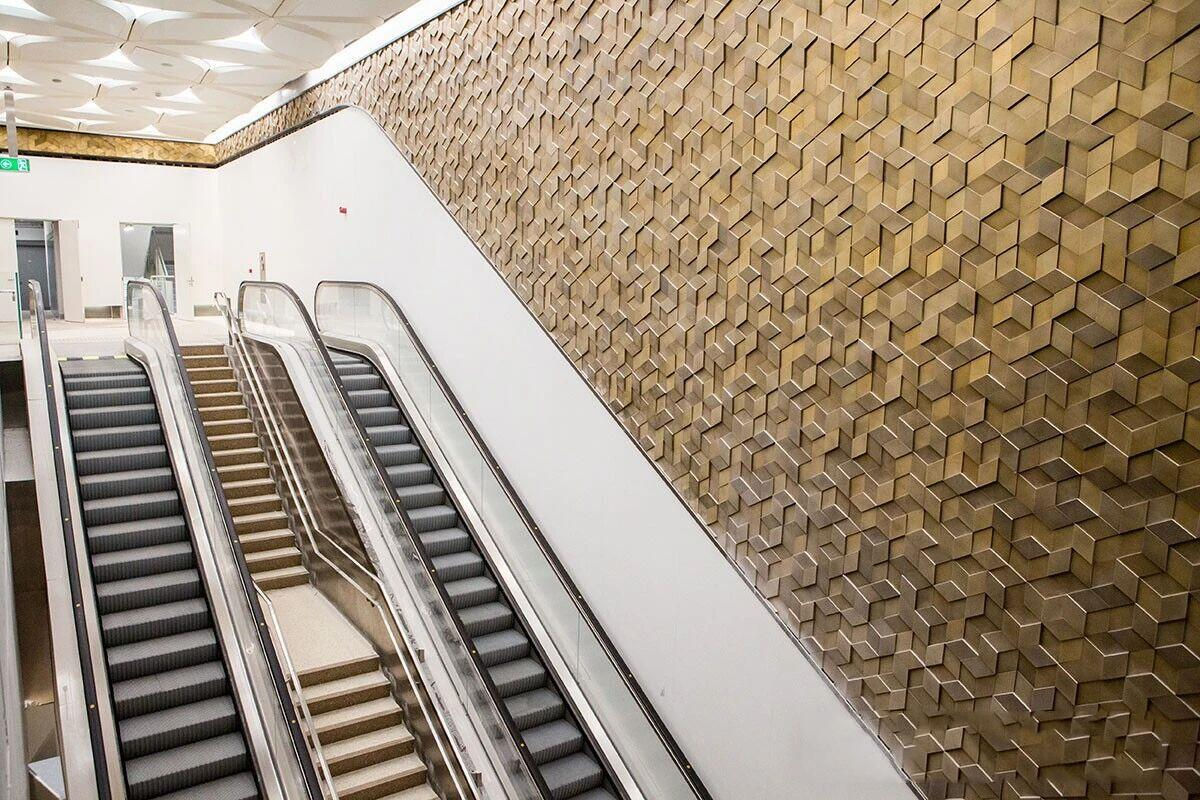

Take the 3D geometric panel system for the Doha Metro. Before any of the 50,000+ panels were mass-produced, we fabricated a 1:1 mock-up in our factory.

This factory build allowed us, the architect, and the general contractor to:

Validate the Shop Drawings: We confirmed that the digital model (深化设计) translated perfectly into a physical product.

Test the Installation System: We tested the mounting brackets, the alignment, and the load-bearing capacity in a controlled environment.

Perfect the Seams & Tolerances: We identified and solved potential alignment issues at complex junctions before they could become an on-site problem.

Finalize Aesthetics: The client could see and approve the true reflection of the PVD finish and the visual impact of the panel-to-panel seams.

Every challenge we solve in the factory is a problem we prevent from happening on-site.

Build #2: The Final Installation (A Predictable Success)

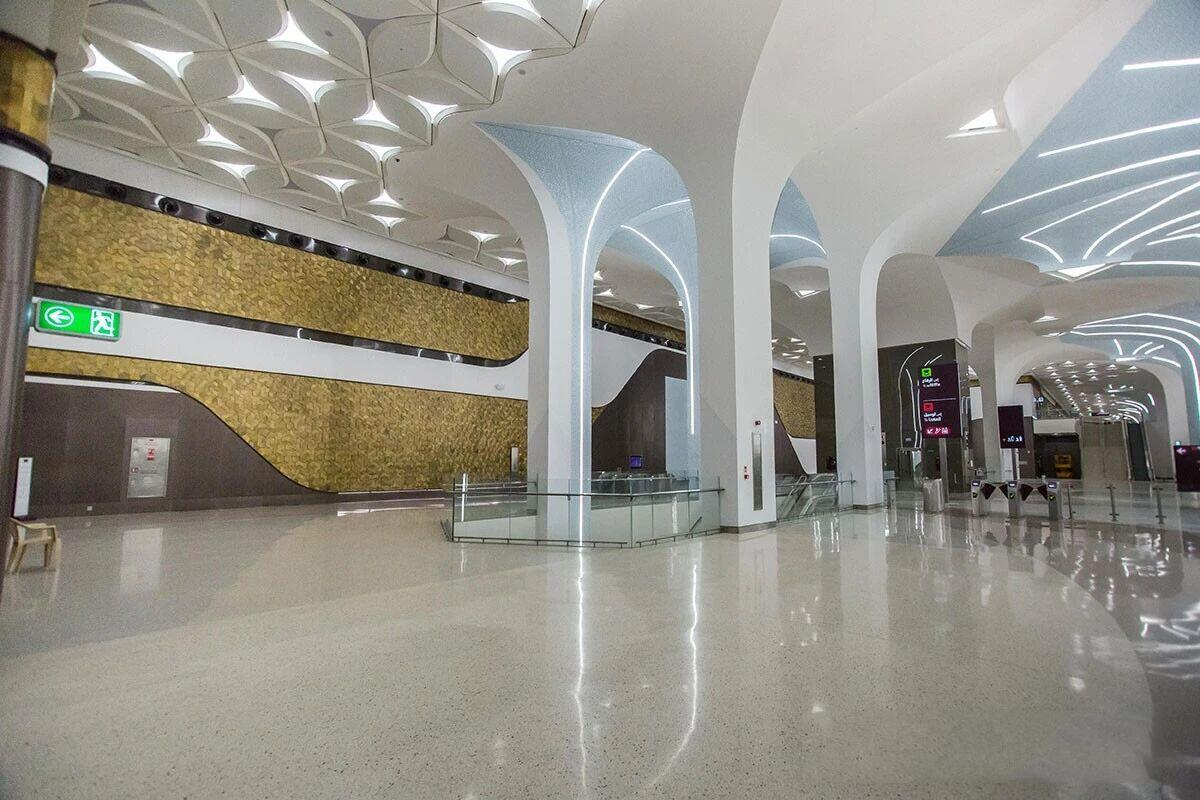

Because of the rigorous mock-up process, the final on-site installation in Doha was a matter of execution, not experimentation.

Our installation teams arrived with a proven, pre-verified system. The 50,000+ panels fit together as designed because every challenge—from the complex corner joints to the mounting hardware—had already been solved weeks before in our factory.

The result is a flawless final installation, delivered on time and without costly on-site errors or delays.

Conclusion: More Than a Sample, It’s Your Project Insurance

The 1:1 mock-up is the critical bridge between ambitious design and precision engineering.

For the architect, it guarantees your vision is buildable. For the contractor, it guarantees a predictable, reliable, and efficient installation. For us, it’s simply the correct way to be a premier fabrication partner. It’s not an extra step; it’s our promise of reliability.

Search

Recent Comments

Recent Posts

- An Architect’s Guide to PVD Coating: Why It’s the Superior Finish for High-Traffic Luxury Spaces November 21, 2025

- From 0 to 50,000+: The Quality Control & Mass Production of 3D Gold Panels for the Doha Metro November 21, 2025

- From Mock-up to Masterpiece: A Case Study in Precision Metalwork for the NBK HQ November 21, 2025

- More Than a Cover: How Column Cladding is Redefining Commercial Lobbies November 21, 2025

- Why We Build it Twice: The Critical Role of the 1:1 Mock-up in Our Process November 21, 2025